Nidec Develops Technology to Achieve the World’s Highest Space Factor for Round Winding Wires

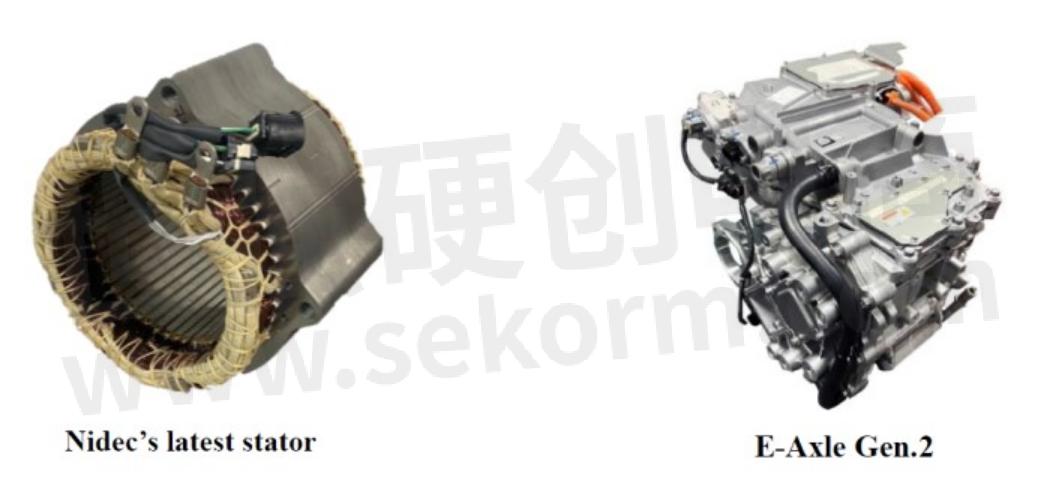

Nidec Corporation(“Nidec” or the “Company”) announced that it has achieved the world’s highest-level pace factor for round winding wires used for its traction motors, and has launched the mass production of motors by using the technology.

Weight saving is one of the critical elements in improving EVs’ electricity efficiency. In producing motors, it is an important mission to improve their efficiency and output to make them smaller and lighter, and making such motors essentially requires improving their coil space factors*1. Nidec’s second-generation E-Axle model (“E-Axle Gen. 2”), which has an optimized slot shape and uses newly developed unique coil insertion equipment, has successfully improved the coil space factor by 6% compared with its predecessor, E-Axle Gen. 1. In addition, the E-Axle Gen. 2 model, with enhanced output characteristics, has a motor section 10% smaller than the previous model.

A common way to improve the space factor is to use the hairpin method, which employs rectangular wires that can fit into a square slot more easily than round ones, though, on the other hand, this method requires a complex production process and a massive amount of capital investment. To counter this issue, Nidec, aiming to produce high-performance and yet low-price E-Axle units (the concept behind the development of E-Axle Gen. 2), continued to use inexpensive round winding wires, while developing a new wire-winding technology to reduce the loading application rate during coil insertion by 80% compared with the conventional technology. Thus, the Company successfully lessened the damage to the coil during its insertion process, achieving both high performance and low cost.

As the world’s leading comprehensive motor manufacturer, Nidec stays committed to fully utilizing its technologies to develop light, thin, short, and small, high-efficiency, and controllable products, and to propose, at an overwhelming speed, revolutionary solutions that contribute to the evolution of automobiles.

*1. Coil space factor: The rate of copper wires to a stator’s space (slot) to accommodate a coil. As part of a motor’s feature, its output increases, as does the number of copper wires inside its stator. However, to make the motor compact, a coil must be placed efficiently, without creating an empty space.

- +1 Like

- Add to Favorites

Recommend

- Nidec’s Traction Motor System, E-Axle 200kW Model, Drives the First Model of Geely Automobile Group’s Premium EV Brand, Zeekr

- The 250kW and 180kW Models of Nidec’s E-Axle Traction Motor System are Officially Adopted for the Car to Commemorate GAC New Energy Automobile’s Production of 20 Millionth Vehicle

- Nidec Power Train Systems Develops New EOP to Cool EV Traction Motor System E-Axle

- Nidec Launches Mass Production of its Second-generation EV Traction Motor System E-Axle Gen.2, which is Lighter and Quieter

- Nidec Machine Tool Launches ZFA Series, Global-standard Gear Grinders that Meet the Global Needs for High-precision Gear Machining

- Nidec Develops AC Servo Motor Equipped with Zignear® , the Location Detection Technology that Accommodates 17-bit Resolution, for the Industrial Robot Market

- Nidec and Renesas Collaborate on Semiconductor Solutions for Next-Generation E-Axle for EVs

- Nidec Launches a Lineup of VR Series Servo Motor Reducers for Food Machinery, Achieving a Torque of up to 80% of Standard Models

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.