Renesas Has a Dual-source Manufacturing Strategy for Both Back-end and Front-end Manufacturing in MCU Supply

In his REcent Live Market Briefing, Hackenberg reviews the timeline and various causes of how the microcontroller supply chain – typically 90% of all semiconductors shipped – arrived at its current state of imbalance. Among the reasons he cites are:

·Pre-pandemic geopolitical conflicts, mostly over tariffs and stockpiling

·Catastrophic weather events and accidents

·Workforce shutdowns due to COVID

·Pandemic-induced reductions – then unexpected increases in demand for components

·Retooling of foundries to accommodate demand for specialized MCUs

·Unpredictability of delivery due to COVID-related shipping congestion

·UnchaRActeristic MCU price uptick of more than 10-15% to accommodate premium foundry services

Only five semiconductor companies produce 80% of the world's MCUs, says Hackenberg, and Renesas, we’re proud to report, is at the top of the supplier list with 19% of the market.

Right about now you might be wondering, “Wait. Wasn’t there a fire in Renesas’ Naka, Japan, fab this past summer? How is it even possible that Renesas is the top supplier of MCUs?”

In a word: Redundancy.Yes, the foundry fire was unfortunate and especially untimely, given the ongoing effects of COVID on the microcontroller supply chain. But disruptions can – and do – happen. Ten years ago, it was an earthquake that unleashed a tsunami and a resulting nuclear accident. Today, it’s the pandemic. Tomorrow, it may be something else.

Building Business Continuity

At Renesas,they have learned from these past experiences to navigate disruption. They use business continuity management best practices to prepare for disasters and manage risks. Their goals are to protect the safety of employees, and, of course, to fulfill responsibility to supply you with products and services. Part of that effort is building redundancy into production lines, and innovation into their product families.

Many Sources Eliminate Supply Failures

Renesas has a dual-source manufacturing strategy for both back-end and front-end manufacturing. Simply put, tthey use own fabs as well as third-party fabs. So if there’s an interruption on one line, they boost production on another.

For example, they fabricate their secure RA microcontrollers, high-performance RX microcontrollers and low-power RL78 microcontrollers among a network of three Renesas-owned foundries and three additional outsourced foundries. There’s simply no chance of a single point of failure.

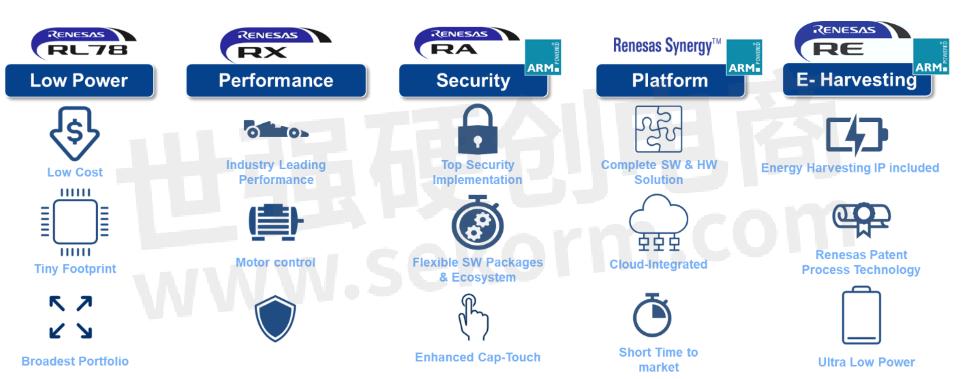

And they coordinate with semiconductor distributors who know first-hand your supply chain concerns. Their on-the-ground customer intelligence guides the short- and long-term product planning for five microcontroller families (Figure 1). So as your products become more sophisticated, you can be sure Renesas’ll have MCUs that support your future designs.

Figure 1: Renesas MCU product lineNo Need to Wait

Rather than wait for a supply chain reboot in 24 months, why not choose a safe bet now? Find the right MCU for your design with the easy-to-use MCU selection tool or download the Renesas MCU guide app and move your manufacturing forward today!

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.