Application of Linear Motors in Semiconductor Industry

Introduction

In China, the research and manufacture of linear motors can be traced back to the late 1950s. It is mainly based on the products used or developed by colleges and universities and scientific research institutions to study some devices; our country began mass production for linear motors from the late 1960s to the early 1970s, which have been put into use in various industries in the early 1970s; the production and research of linear motors have achieved breakthroughs from the mid-1970s to the mid-1980s; the finished products were in the development stage and high-performance electric motors new varieties are constantly being developed. Since the mid-1980s, a lot of research work has been done on the accurate model of linear motors, and various hybrid linear motors and drives have been widely used as products. For more than 20 years, direct-drive linear motors have significantly improved performance in numerous applications, including numerous high-tech industry applications. Today, direct drive technology is an advanced solution for the high productivity, high precision, and dynamic performance of modern machines.

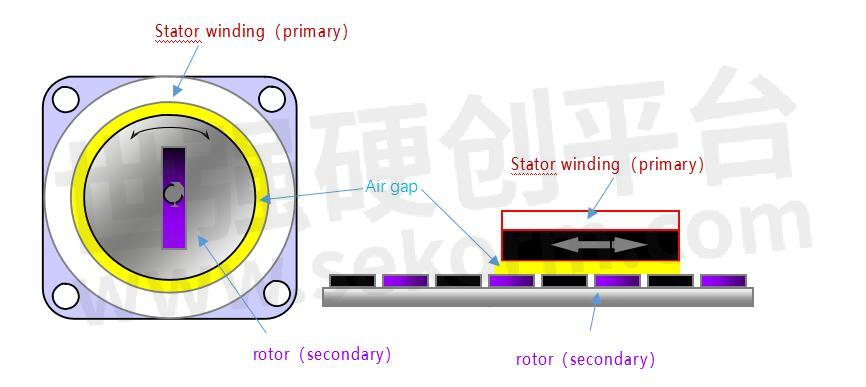

In real life, our common motors are basically induction motors with rotating motion, which are widely used in household appliances, automobiles, industrial equipment, and other industries. The principle of linear motors can be understood as a rotating motion induction motor cut in the direction of diameter and flattened into a linear motor. Taking the induction motor of rotating motion as a reference, in a linear motor, it is equivalent to the stator winding of the rotating motor (called the primary), and it is equivalent to the squirrel rotor of the rotating motor (called the secondary), and the secondary surface is equipped with permanent magnets. If the secondary is fixed, the primary passes alternating current and moves in a straight line along the secondary under the action of electromagnetic force. On the contrary, if the primary is fixed, then The secondary moves in a straight line along the primary.

The linear motor is a brushless synchronous motor, and the common linear motor is a flat structure or circular structure. By electromagnetic induction interaction between the primary (coil winding) and the secondary (permanent magnet), electrical energy can be efficiently converted into mechanical energy of linear motion. Since linear motors can generate large force at low speeds even at a standstill, in the definition of motor specifications, continuous force, and peak force are mainly defined, rather than power and torque as traditional motors are defined. The mounting holes of the moving parts of the flat linear motor can be directly connected to the load of the machine, which can make the machine compact, simplify the machine structure design, without backlash, and will not have failure parts with other transmission mechanisms, such as servo linear guide ball screws Lever, coupling, belt or other mechanical transmission parts. Finally, linear motor motion systems have wider bandwidth and higher rigidity, resulting in high accuracy and repeatability at high speeds. Based on the above advantages, linear motors can be widely used and developed in various major industries.

Several common structures of linear motors

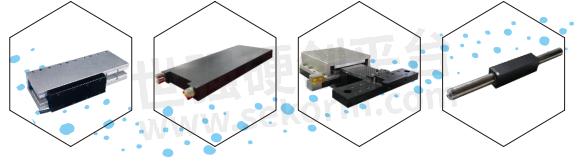

Iron core linear motor, ironless linear motor, slotless linear motor, magnetic axis linear motor (voice coil motor), tubular linear motor.

Semiconductor Industry Introduction

Affected by the global economy and the epidemic, the shortage of chips has become an important issue in various industries. Therefore, the semiconductor industry is one of the industries with rapid development in recent years, and it is one of the hot topics in the science and technology industry. Under the trend of global information, the information industry has become an extremely important industrial pillar of the global economy, and the semiconductor industry is equivalent to the heart of the information industry. The semiconductor industry has become an important part of people’s life. At present, semiconductor components have become indispensable elements in industries such as automobiles, home appliances, mobile phones, and industrial intelligent equipment.

From the summary of various information, we know that semiconductor materials and equipment are supporting the industry of semiconductors, and they have become the top priority under the current international trade relationship. The semiconductor equipment is related to the semiconductor process technology. At present, the relatively mature process technology has a tight production capacity. Benefiting from the strong demand in new fields such as big data, 5G technology, intelligent driving, new energy vehicles, and AI, the wafer manufacturing market has multiplied growth, and advanced manufacturing processes will play an important role, thus it has higher demands on semiconductor equipment.

The entire processing process of semiconductor products is relatively complex, including various precise processing, mainly including wafer manufacturing (Front-End) and packaging (Back-End) test. With advanced packaging technology, the processing link between manufacturing and packaging is called the Middle-End.

The wafer production line can be divided into seven independent production areas: Thermal Process, Photo-lithography, Etch, Dielectric Deposition, CMP, and Metalization.

Traditional packaging (back-end) testing is roughly divided into eight production processes, including backside thinning, wafer dicing, SMD, wire bonding, molding, electroplating, cutting, forming, and final testing. Simple, less technically difficult, and less demanding than wafer manufacturing for a process environment, equipment, and materials.

Due to there are many processing steps of semiconductor products, a large number of semiconductor equipment is required in the manufacturing process, such as lithography machines, etcher machines, plastic film packaging and testing, wire bonding machines, die bonding machines, and sorting machines, and laser marking machine, dicing machine, etc. Semiconductor equipment has continuously put forward higher requirements for high-speed, high-precision, high-performance, and high-speed; the transmission and its control have higher dynamic characteristics and control accuracy, higher speed and acceleration, and lower wear and tear.

Therefore, high precision and high repeatability linear motors are more suitable for becoming an important part of semiconductor processing equipment.

Application of Linear Motor

Linear motors have been applied to different degrees in different processing and manufacturing fields. At the same time, they provide more process options for various processing methods, directly or indirectly participating in technological changes. In other words, linear motors also satisfy the needs of the semiconductor industry, and linear motor technology can improve the performance of semiconductor equipment. The semiconductor industry has introduced the application of linear motors for a long time due to their characteristics of positioning movements and frequent rotations. Semiconductor equipment may contain a linear motor stage or multiple linear motor modules, so as to meet different operation instructions and complete the production of semiconductor components.

Mainly Applications:

1. XZ axis stage in the high-speed high precision mounting machine- U-type linear motor is used for X-axis positioning, and voice coil motor is used for Z-axis to quickly pick and place chips, it is suitable for equipment that requires force control. The application of linear motors can meet the requirements of high acceleration, high speed, high precision, and high frequency.

2. XY axis stage in the Die bonder is the key equipment for the subsequent packaging process of the semiconductor, which realizes the die automatic pick up from the wafer and placing it on the lead frame. Due to process and efficiency requirements, the XY axis has extremely high motion speed and acceleration. Linear motors on both sides are used for X-axis positioning, and wafer positions are used for Y-axis positioning.

3. XYZ axis stage in wire bonding machine, the linear motor system is used in the wire bonding machine which provides high-speed motion along different X-aixs, Y-aixs, Z-aixs, and the linear motor has a long stroke, which can provide a larger wire bonding platform to meet the wide range of welding needs.

4. Linear motor and voice coil motor double workpiece stage in lithography machine, linear motor is one of the core systems of the lithography machine, main function is to carry the wafer to perform high-speed ultra-precision motion according to the specified motion trajectory, including loading and unloading, alignment, wafer profile measurement, and exposure, etc. The lithography machine has two workpiece tables, that is there are two workpiece tables that carry wafers in one lithography machine. The two workpiece tables are independent of each other but run at the same time. When the wafer on one workpiece table is exposed, the other workpiece table makes preparation work before exposure such as measurement of the wafer. When the exposure is completed, the two workpiece tables exchange positions and functions, and thus achieve high productivity of the lithography machine in circles.

In addition to the application fields mentioned above, linear motors are also widely used in various semiconductor equipment, such as PCB drilling machines, semiconductor wafer handling robots, semiconductor wafer polishing platforms, wafer cutting, wafer testing, wafer packaging, etc. It can be considered that linear motors are already an important part of semiconductor equipment.

Summary

With the fast development of the semiconductor industry, the demand for semiconductor components has also continued to grow with diversified requirements, and there will be higher requirements for semiconductor equipment; linear motors and motor stages have provided high-speed and high repeatability performance in semiconductor equipment, thereby promoting the development of semiconductor industry.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.