Introduction to NOVOSENSE Sensor Solution Applied in xEV

Aiming at the important market segment of new energy vehicles, NOVOSENSE's rich sensor products enable automotive electronic solutions, including a magnetic current sensor in the battery, motor and electric control system of the new energy vehicle, magnetic angle sensor in the thermal management system, MEMS pressure sensor in BMS system, as well as various MEMS pressure sensors, oil pressure measuring sensors and signal conditioning chips for hybrid vehicles and traditional fuel vehicles.

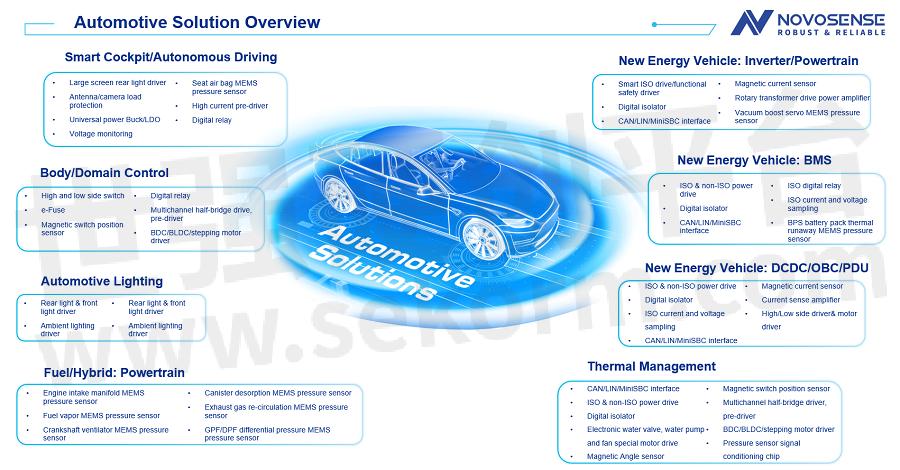

Caption 1: NOVOSENSE sensor solutions in new energy vehicles

The magnetic current sensor in the battery, motor, and electric control system of the new energy vehicle

The magnetic current sensor is mainly used in the battery, motor, and electric control system of the vehicle. OBC/DCDC uses a Hall current sensor, which can realize current feedback and overcurrent protection by current sampling on the PFC end of the OBC input side and the high voltage output end of DCDC. The detection current is generally tens of amps, the sampling delay is less than 3μs, and the sampling accuracy is about 3%. This application usually uses a wide-body SOIC-16-pin patch Hall current sensor.

In contrast, in electric drive systems, the current is usually up to hundreds of amps, so a linear Hall current sensor or linear Hall sensor module shall be used. NOVOSENSE offers the patch coreless linear Hall current sensor NSM2020 and the linear Hall current sensor NSM203x series. The next-generation products are also under development.

The NSM201x comes in five models, with the even-ending NSM2012 and NSM2016 being 8-pin packages, and the odd-ending NSM2011, NSM2013, and NSM2015 being 16-pin packages. The difference is that the NSM2012 does not have an overcurrent protection output pin, and supports proportional output and fixed output.

NSM2016 supports overcurrent protection output and fixed output; NSM2011 supports proportional output but does not support overcurrent protection output. NSM2013 supports fixed output and does not support overcurrent protection. NSM2015 supports both fixed output and overcurrent protected output.

OBC mainly uses chips with 16-pin packages, that is, NSM2011 and NSM2015. NSM2011 and NSM2011 are wide-body 16-pin packaged patch Hall current sensors with measuring ranges from 20A to 100A, supporting 3.3V or 5V power supply, with a bandwidth of 240kHz, and delay of 2.2μs. Due to the temperature compensation design and pre-delivery correction, the chip can achieve measurement accuracy of 2% in the whole temperature range, fully meeting the requirements of the OBC sensor; The chip can reach an insulation voltage of 5000V and basic insulation working voltage of 1550V.

In contrast, NSM2015 has a bandwidth of 320kHz, a delay of as low as 1.5μs, and a measurement accuracy of 2% in the full temperature range, with the same withstand voltage and reliability as those of NSM2011. The difference is that NSM2015 also supports overcurrent protection output and supports user overcurrent point configuration. Both NSM2011 and NSM2015 are compatible with mainstream competitive models in the market.

NSM203x Hall current sensors include NSM2031, NSM2031F, NSM2032, and NSM2033. NSM2031 and NSM2031F support 240kHz bandwidth and 2.2μs delay, and have the function of dynamic range OTP programming from 0.5 to 15mV/G. The NSM2031F supports overcurrent protection output, and the NSM2032 and NSM2033 support 400kHz bandwidth and 1.8us latency. Upgrading from OTP to MTP programming improves flexibility and helps customers improve batch production yield. NSM203x series adopts TO94 straight pin and folding pin package; The NSM2032 supports reference voltage output and the NSM2033 supports overcurrent protection output.

The parameters of the NSM2020 are similar to those of the NSM2033, but its TSSOP8 package makes it easier for OEMs to integrate current sampling capabilities, simplify system design and reduce overall cost. Because NOVOSENSE adopts the method of detecting the vertical magnetic field, the chip has a strong suppression ability to the common mode magnetic field and can realize the high-precision current detection without a shield.

For the above automotive-qualified magnetic current sensors, NOVOSENSE can provide an automotive-qualified AEC-Q100 test report, PPAP file, and safety certification.

Angle sensor in the thermal management system

The thermal management system of new energy vehicles requires water pumps and water valves to balance the temperature between different modules and components. For thermal management systems, NOVOSENSE has developed system solutions, including pump motor driver SoC, water valve feedback angle sensor, and BLDC motor commutation magnetic switch. NSM301x is a series of chips based on the Hall principle. It adopts the angle detection principle of four Hall disks and completes angle measurement with Cordic angle calculation. MTP supports zero output data configuration, 4-segment linear calibration, etc., and the output angle accuracy can reach 1 degree or even as low as 0.2 degrees after correction. NSM301x has various output forms, including analog, PWM, 3-wire SPI, UVW, and so on. At present, this series of sensor chips has been mass-produced.

MEMS pressure sensor for BMS

To solve the thermal runaway problem of automotive BMS (battery management system), NOVOSENSE introduces the MEMS pressure sensor for early pressure detection of thermal runaways. The NSPASx series MEMS pressure sensors support a measurement range of 10 to 400kPa with an accuracy of better than ±1%. The NSPASx series MEMS pressure sensors can also be used for airbag pressure detection in car seats to improve seat comfort for passengers, as well as vacuum detection of vacuum pumps in vacuum-assisted brake systems.

Sensors in hybrid/fuel car powertrain and fuel supply

Different from new energy vehicles, hybrid vehicles maintain the original fuel vehicle design. NOVOSENSE offers various types of MEMS pressure sensors, oil pressure measurement sensors, and signal conditioning chips, which can be pin-to-pin compatible with other solutions on the market, depending on the model and application scenario. In addition, NOVOSENSE has developed a complete product roadmap for both resistive and capacitive pressure sensor signal conditioning ASICs, with different series of products supporting different output types, including analog output, SENT, and LIN bus output, to meet different customer needs.

- +1 Like

- Add to Favorites

Recommend

- NOVOSENSE Launched NSM2015/NSM2016 Series Hall-effect Current Sensor Chip with High Isolation and Overcurrent Protection Function

- NOVOSENSE Launched the Automotive-qualified Integrated Current Sensor NSM2019 Featuring Low Impedance and High Isolation

- NOVOSENSE Has Launched Multiple Automobile-qualified Chips with Breakthrough Innovation Technology In the first half of 2022!

- Novosense Selects Tower Semiconductor for Volume Manufacturing of their Magnetic Sensor for the Automotive On-board Charger Market

- NOVOSENSE Assists the Formulation of LIN Transceiver Chip Standard, Promoting the High-quality Development of the Automotive Chip Industry

- NOVOSENSE Won VDE Premium Quality Award for High Quality Development

- Low Impedance, High Current Capacity, NOVOSENSE Introduces Integrated Current Sensor NSM2311 for Power Supply Applications

- Automotive Chip Provider NOVOSENSE Has Officially Become a Member of Automotive Electronics Council

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.