Why Do Molding Chokes Need Separate Bias Current Testing?

Given the steady growth of the global automotive market and its strict safety standards, the functions and specifications of automotive electronic components need more rigorous and complete testing. Take inductors as an example. Generally, manufacturers of inductors only conduct the inductor bias current test on a sampling basis. Recently, however, a major Tier 1 manufacturer of molding chokes has instead set this bias current test as a screening item for their entire production line.

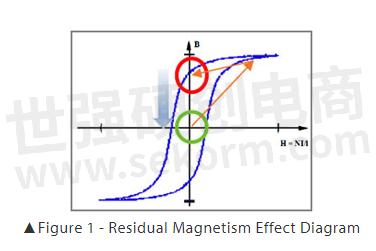

Nevertheless, after the inductor has undergone the bias current test, remanence will cause a momentary move in the B-H magnetic curve and prevent it from returning to the zero point (Figure 1). This will briefly affect the Ls/Q-value of the inductor. Common high-inductance products are more prone to such phenomena due to the use of higher magnetic permeability materials.

A magnetic material with higher remanence (higher μ) will have a temporary change in inductance or a lower Q-value due to differences in the characteristics of its magnetic field. It usually will recover after knocking, resting at a high temperature, or a long rest. Therefore, if the bias current test is integrated into the inductor test and packaging machine, the Ls/Q-value gets insufficient rest time after excitation from the bias current test, which then will cause production problems. This means that a test setup combining the bias current test and the Ls/Q-value test into one automatic test and packaging machine does not fit for certain inductors, necessitating a separate device purely for testing the bias current specifications. The main reasons are:

1.Reduced impact of the bias current test on the no-load Ls/Q-value.

2.No need to modify the design of existing test and packaging machinery to accommodate additional testing.

3.Additional pre-screening is limited to products that require bias current testing, reducing the amount of products that need to meet specific test requirements.

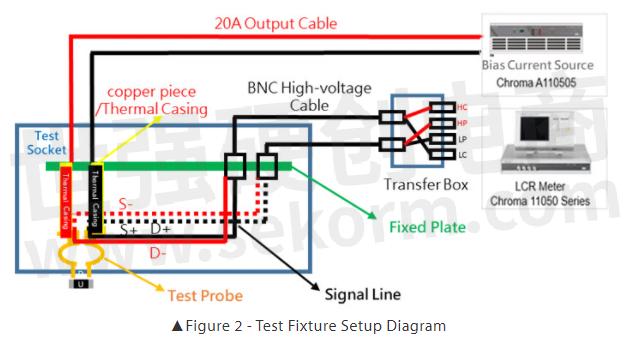

During the test, additional bias current must be applied to the test object. Therefore, the entire inductor bias current test station must be equipped with a test probe and conductor configuration developed for large withstand currents to ensure reliable and stable test results. CHROMA has specifically designed CHROMA 1871B Inductor Bias Current Automatic Test Machine with a test socket and test probe that can withstand large currents of >20A (Figure 2). The accurate and fast precision measurement instruments of Chroma 11050 Series HF LCR Meter and Chroma A110505 Bias Current Source are incorporated for better test reliability and stability. Moreover, the dedicated data collection software not only monitors the quality in real time, but also keeps focus on the set requirements for overall operating quality.

Recently, a major Tier 1 manufacturer of molding chokes has assessed the benefits of CHROMA 1871B Inductor Bias Current Automatic Test Machine. The test equipment not only saved them costs for setup changes and labor as well as improved their production capacity, but more importantly, also increased the accuracy of their test results. As a result, the manufacturer embedded Chroma 1871B in the production line and set the bias current tester to operate separately from the inductor test and packaging machine.

CHROMAprovides complete solutions for these and other inductor test applications. Feel free to ask us any questions you may have. We are happy to be of service.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.