DA Technology SMD big current fuse SF331 was successfully applied to the overcurrent protection of AGV

Automatic guided vehicle AGV (Automatic Guided Vehicles) is a kind of unmanned handling equipment and one of the important transportation tools in modern automated smart factories. With the rapid development of the global economy, modern automated production concepts are increasingly being valued by enterprises, and the application fields are also expanding, including the automobile industry, aircraft manufacturing, home appliance industry, tobacco industry, machining, warehouses, logistics, post and telecommunications, etc. This also provides an opportunity for the development of the automated guided vehicle industry.

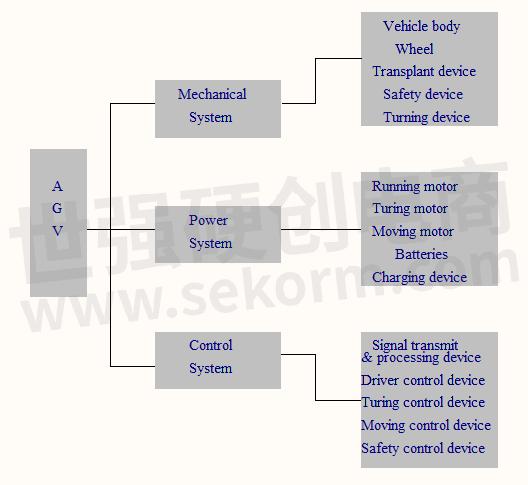

The structure of AGV is shown in the figure below

According to the guidance method ,AGV is classified into electromagnetic guidance, optical guidance, tape guidance, laser guidance, inertial guidance, two-dimensional code guidance, etc.The power supply of AGV is usually 24V or 48V DC lead-acid battery or lithium battery.

With the development of the lithium battery market and the decline in unit costs, the advantages of lithium batteries have become more and more obvious. Therefore, more and more charging and discharging equipment use multiple strings of lithium ion battery packs as power supply. However, because lithium ions are more sensitive to overcurrent, overvoltage, overtemperature, etc, it is usually necessary to add a BMS management circuit to detect and manage its charge and discharge.

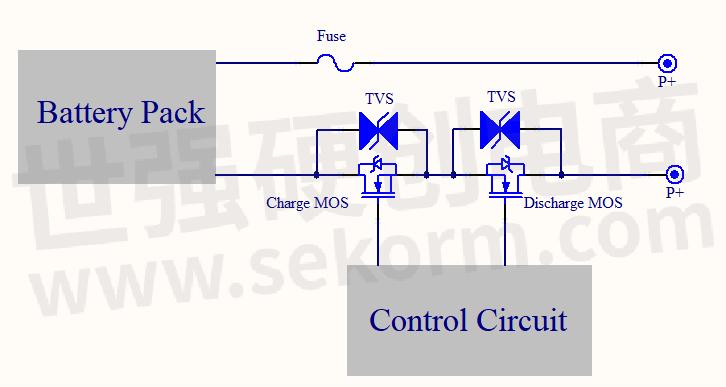

The typical management circuit is shown in the figure below

It is generally divided into two levels of protection. The first level of protection is controlled by MCU or the lithium battery management IC, to manage the charging and discharging MOS is turned on and off. The second level protection is usually connected fuse in series with the main circuit of the lithium battery. In order to prevent abnormal conditions such as over-current or short-circuit on the circuit when the control chip fails, the fuse is blown in time and the circuit is disconnected. If the fuse is not used to cut the circuit in time, the heat generated by the circuit is likely to cause damage to the equipment, or even fire.

The traditional fuse is connected in series on the secondary overcurrent protection circuit. A more prominent problem is that because the fuse is connected in series in the loop, a large current flows through the fuse, and due to the internal resistance of the fuse, thermal power will be generated on the fuse all the time , And then produce the problem of excessive temperature rise, which is brought another potential risk for product reliability.Thus the cold resistance of fuse is much more important to designer .

For this application, DA launched a medium-low voltage, high-current, ultra-low impedance chip fuse SF331 series. Their cold resistance is currently the lowest in the industry, so the temperature rise is also the lowest among the same products.

Its appearance is as shown below

Its characteristics are as follows:

1. Current ranging 15-100A

2. The voltage of SF331 is up to 72VDC (breaking capacity is 600A)

3. High I2T, ultra-low cold resistance (0.35mΩ/80A), low temperature rise, low voltage drop

4. Surface mount 11x4.5MM, UL certified ,file number is E509623

5. Wide operating temperature range -55℃ ~ +125℃

6. Rohs& halogen-free, silver&gold-plated terminals are optional

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.