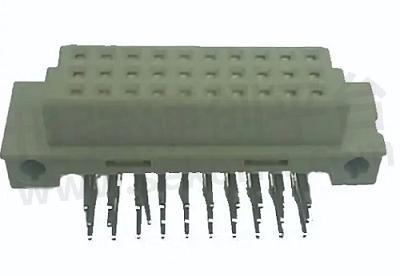

Introduction of Din41612 Connectors

DIN41612 connectors mainly have parallel connections and vertical connections. The connection form is a straight hole - curved needle, vertical connection of curved hole - straight needle, parallel connection of curved hole - curved needle. The number of contact points is 20, 30, 32, 40, 64, 96, 120, 128, 160, etc. The products are used in the connection between the backplane and the daughter board of optoelectronic equipment, the connection between the backplane and the daughter board of industrial control equipment, the industrial control of consumer electronics, the connection between the backplane and the daughter board of industrial control security control, etc. Its application industry: used in consumer electronics, monitors, computers, PCB boards, instrumentation, intelligent robots, electrical appliances, new energy vehicles, color TVs, air conditioners, photovoltaics, security, mobile phone industry, CNC, and other industries!

There are 2A, 6A, 15A, etc., signal types, power types,s and mixed types of different media, the product has a wide range of applications. There are four installation forms of backplane, parallel board, common panel, and wire-to-board, which can quickly connect and improve work efficiency.

Classification

Classified by working on current

Ordinary type (2A), high current type (6A), power type (15A).

Classified by Termination Form

Soldering type, crimping type, crimping terminal type, IDC piercing insulation type.

Din41612 connectors are generally used for signal or power connection below 3MHz, and are not suitable for signal connection above 10MHZ; when used for 3~10MHZ signal connection, an isolation method is required, and ground pins are inserted between each signal pin to avoid two Adjacent signals influencing each other, resulting in greater crosstalk.

There are two installation and fixing methods, one is the harpoon fixing method. In this method, the fixing pin will be welded to death during welding, which is not conducive to maintenance and disassembly. The other is the screw-fixing method. This method needs to be matched with screws, nuts, flat washers, and gaskets. The process operation is more complicated, and the advantage is that it is easy to disassemble. When the technological level reaches a high level, it is recommended to use a harpoon and a screw-fixing method is recommended at this stage. When the European connector has insulation requirements, the selection of electrical clearance and creepage distance should be considered.

- +1 Like

- Add to Favorites

Recommend

- What Are the Types of Backplane Connectors?

- Mission Critical: Maintain your RF cables and connectors 24 APR Mission Critical: Maintain your RF cables and connectors

- Summary of Three Common Fault Modes in Automotive Connectors

- What Are Connector Pitches?

- How Board-to-Board Connectors are Made Robust and Which Influencing Factors Affect the Connector

- What is the Difference Between FFC and FPC Connectors?

- Judgment Method of Waterproof Connector Quality

- Antenk Electronics Appeared in Guangzhou International Intelligent Manufacturing Exhibition with A Series of High-performance Connector Application Solutions

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.