Shindengen Newly Launch An Ideal Diode IC with Reverse Connection and Reverse Current Protection Which Reduces Conduction Dissipation by 55%

Shindengen Electric Manufacturing Co., Ltd. has begun sales of the MF2003SV IC V-DiodeTM ideal diode IC for reverse connection protection and reverse current protection applications.

By integrating a Pch MOSFET with a reverse connection protection and reverse current protection circuit, this product contributes to lower dissipation for electronic devices.

The product also contributes to downsizing through a reduced mounting area and number of components compared to conventional diodes.

■ Overview

Power consumption has increased in automobiles in recent years due to more advanced electronic devices, functional integration, and greater multi-functionality. Conventionally, diodes have been used for reverse connection protection and reverse current protection elements in ECU input parts, however, increased dissipation and heat generation from diodes resulting from increased current were impediments to equipment heat dissipation measures and downsizing. As a result there has been demand for reverse connection protection and reverse current protection elements which can control this dissipation and heat generation.

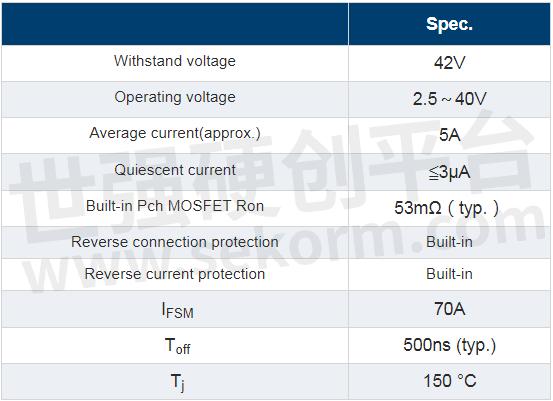

Compared to conventional diodes, this product reduces conduction dissipation by 55%, reduces temperature increases by 37%, and also reduces mounting area by 75%. This contributes to downsizing and lower dissipation in equipment which requires reverse connection and reverse current protection, such as automotive products, and output ORing applications.

■ Features

· Significant reduction of dissipation and temperature increases [Fig.1]

Use of a Pch MOSFET reduces conduction dissipation by 55% and temperature increases by 37% compared to convention diodes.

· Compact package which contributes to device downsizing [Fig.2]

Utilizes a WSON8 leadless package with wettable flanks to achieve a 75% reduction in mounting area compared to conventional diodes.

· Reduction of voltage drop during conduction

The use of a Pch MOSFET reduces voltage drop during conduction by 38% compared to conventional diodes※1.(Ron=53mΩ typ.)

· Allows for normal operation even under low input voltage

Protects the Pch MOSFET from negative surge voltage caused by steep fluctuations at the input side.

· Equipped with active clamp function

The Pch MOSFET can be switched on even if the input voltage drops during cranking.

· IC consumption current of 3μA during no load(MAX)

Reduces discharge by batteries when vehicles stop by minimizing unit dark current.

· Other features

AEC-Q100 compliance

42V withstand voltage in consideration of load dump testing.

High-speed transient response

※1:Compared to previous Shindengen products.

Fig.1 Significant reduction of dissipation and temperature increases

Fig.2 Compact package which contributes to device downsizing

■ Typical Applications

・Various vehicle installation ECU

Meters, heads-up displays, navigation systems, audio, USB modules, etc.

・Device inputs and outputs which require O-rings

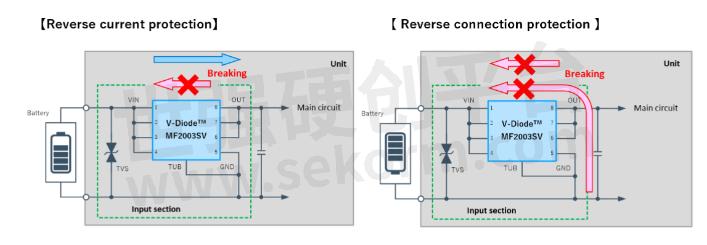

■Circuit examples

■Product Specifications

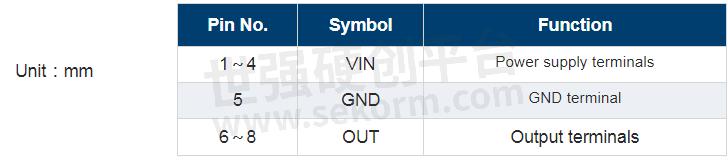

■ External Dimensions Diagram

■ Availability

May 2023.

■ Factory Location

Higashine Shindengen Co., Ltd. etc.

- 【Datasheet】MF2003SV Ideal Diode IC V-Diode™

- V-Diode™ MF2003SV

- 【Datasheet】MF2003SV Ideal Diode IC V-Diode™

- MF2003SV Ideal Diode IC V-Diode™ APPLICATION NOTE

- 【Datasheet】MF2003SV Ideal Diode IC V-Diode™

- 【Datasheet】MF2003SV: Ideal Diode IC V-Diode™

- 服务器的设备

- EPS, auxiliary motors, and other devices for three-phase brushless motors

- Shindengen(新电元)二极管/MOSFET/功率IC/功率模块选型指南

- Shindengen(新电元)二极管/MOSFET/功率IC/功率模块选型指南

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.