Next-Generation Power MOSFETs for Automotive Applications with a 25% Reduction in Mounting Area, Combining a Compact Package with High Current

Shindengen Electric Manufacturing has launched its next-generation power MOSFET "TOLL Package Series" for automotive applications.

With the rapid spread of electrified mobility in recent years, there is a demand for components that can withstand voltages of 100 to 200V and handle high currents, in line with the installation of high-voltage batteries. In addition, in order to increase the flexibility of the design and reduce the weight of the mobility, it is important to downsize the components installed.

In order to meet these needs, we are releasing the "TOLL Package Series" of 5th generation power MOSFETs that comply with the AEC-Q101 automotive reliability standard.

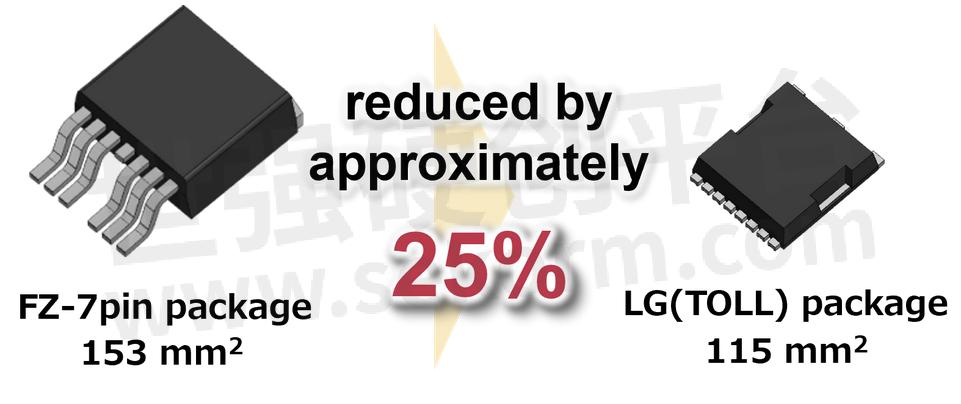

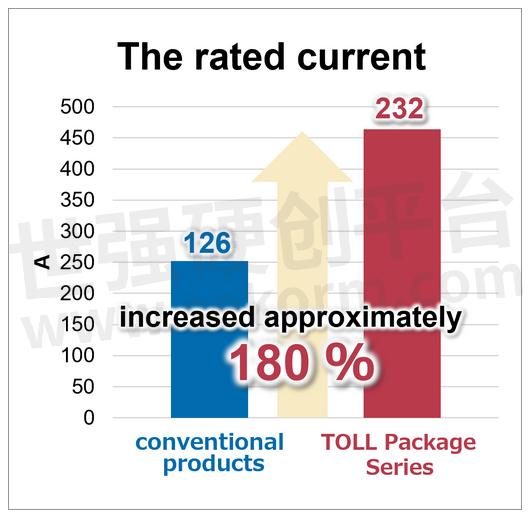

This product has reduced the mounting area by approximately 25% compared to previous products*1 by adopting a new package. In addition, by adopting next-generation chips with a shielded gate structure, the rated current has been increased to 232A, which is approximately 180% of conventional products*2, achieving both compactness and high current.

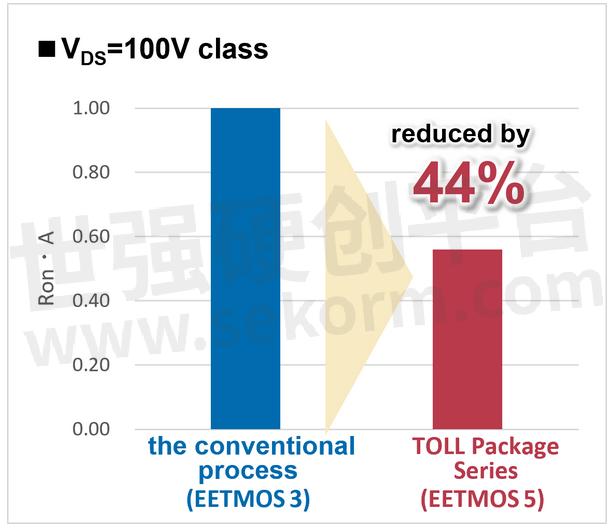

Furthermore, the Ciss/Crss characteristic is improved by approximately 44% compared to conventional products*2, significantly reducing the risk of self turn-on.

We are currently developing 200V-rated products, and we will continue to expand our lineup of high-current power MOSFETs that can be used in vehicles to meet market needs.

※1 Compared to "FZ-7pin(TO-263-7pin)"

※2 Compared to "P126FP10SNK"

Features

1. Reduced the mounting area by approximately 25% [Fig.1]

This product has reduced the mounting area by approximately 25% compared to previous products*1 by adopting a new package.

2. The rated current has been increased to 232A [Fig.2]

by adopting next-generation chips with a shielded gate structure, the rated current has been increased to 232A, which is approximately 180% of conventional products*2.

3. Significantly reducing the risk of self turn-on [Fig.3]

The Ciss/Crss characteristic is improved by approximately 44% compared to conventional products, significantly reducing the risk of self turn-on.

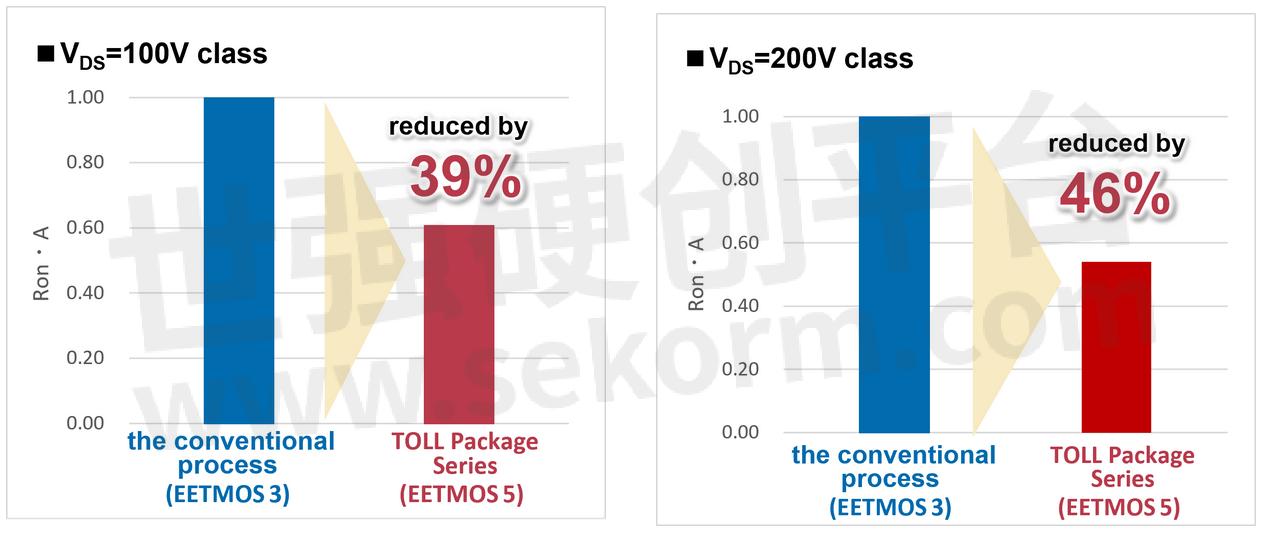

4. Low Ron、low noise product [Fig.4]

Compared to the conventional process, Ron·A was reduced by 39% in the VDS=100V class and by 46% in the VDS=200V class.

5. Other features

Wettable Flank structure

Tch=175℃

※1 Compared to "FZ-7pin(TO-263-7pin)"

※2 Compared to "P126FP10SNK"

Fig.1 Package size comparison

Fig.2 Rating current comparison

Fig.3 Ciss/Crss comparison

Fig.4 Ron comparison

Typical Applications

Large-capacity motor drive

On-board ECU

Reverse contact, reverse flow prevention, etc.

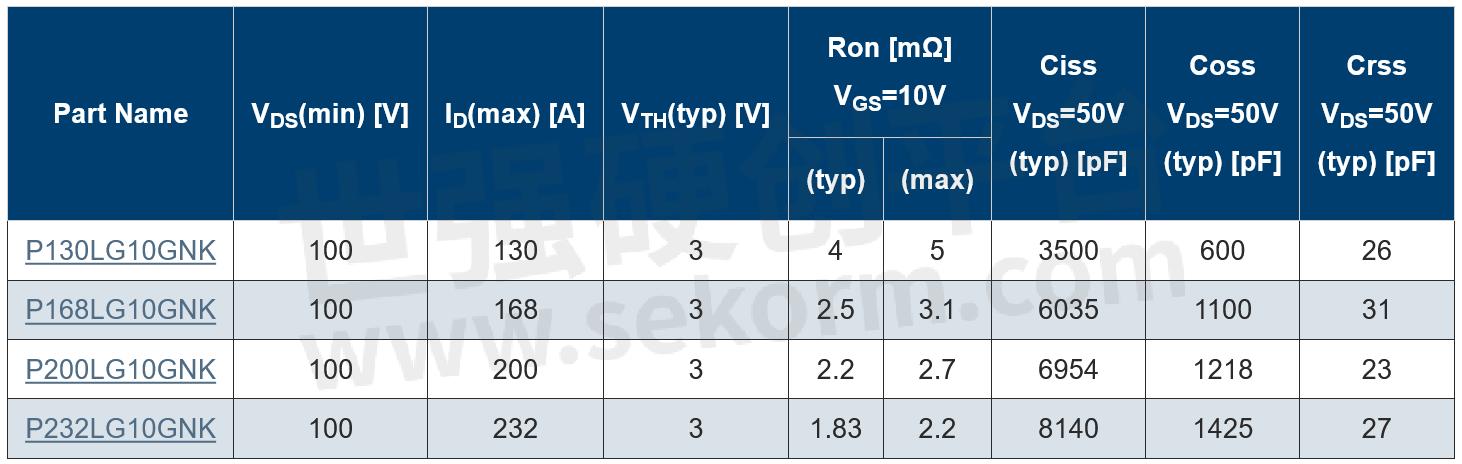

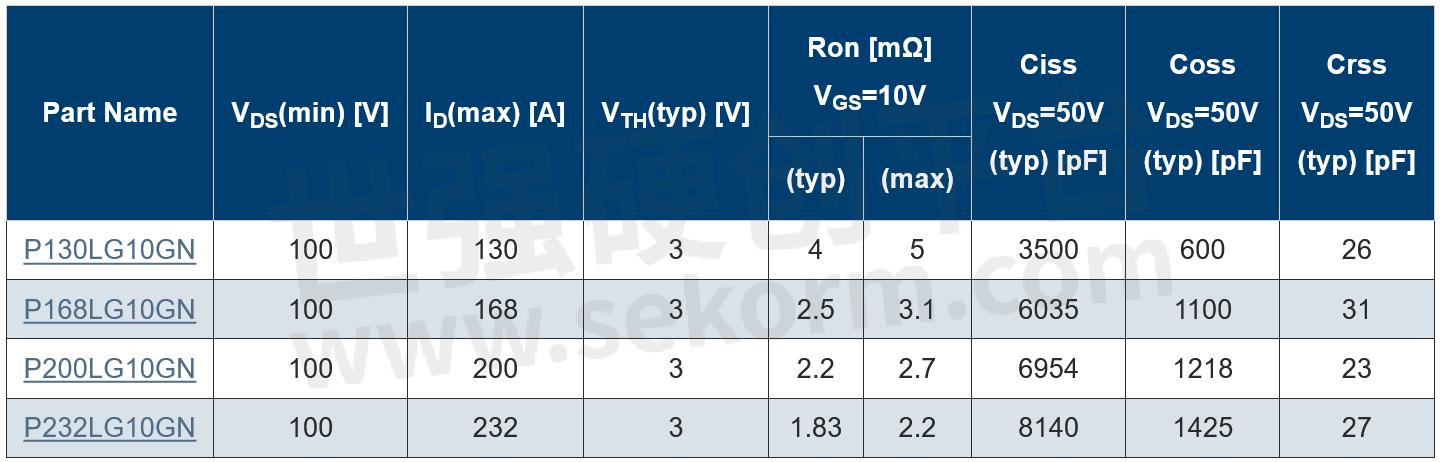

Product Specifications

For vehicle applications

For consumer electronics

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.