Epson Develops an Oven-Controlled Crystal Oscillator OG7050CAN That Consumes 56% Less Power than Conventional OCXOs

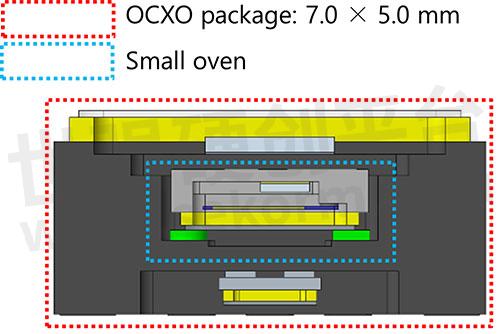

Seiko EPSON Corporation (TSE: 6724, "Epson") has developed an oven-controlled crystal oscillator (OCXO) 'OG7050CAN' that consumes 56% less power than the products in Epson's earlier OG1409 series ("earlier products"). Measuring 7.0 × 5.0mm and with a height of 3.3mm (Typ.), the new OCXO is 85% smaller than earlier products by cubic volume.

New product OG7050CAN

Reference signal sources in wired and wireless backbone communication facilities such as base stations and data centers are subject to strict accuracy and stability criteria. Oven-controlled crystal oscillators are used as a reference signal source in such applications because of their high stability. The crystal oscillator is enclosed in a temperature-controlled chamber ("oven")2. The temperature inside the oven is held constant even when the ambient temperature changes, thereby minimizing frequency drift.

Communication data traffic continues to grow, propelled by the roll-out of 5th generation communication systems (5G), the spread of the Internet of Things (IoT), the use of artificial intelligence (AI) in data centers, and the upcoming 6G services. These changes are expected to cause power consumption at base stations and data centers to sharply increase and drive demand for low-power OCXOs used as reference signal sources.

Left: Earlier product, Right: New product

To meet this demand, Epson drew on its crystal device, semiconductor, and mounting technologies to develop an OCXO that consumes 56% less power and is 85% smaller than earlier products.

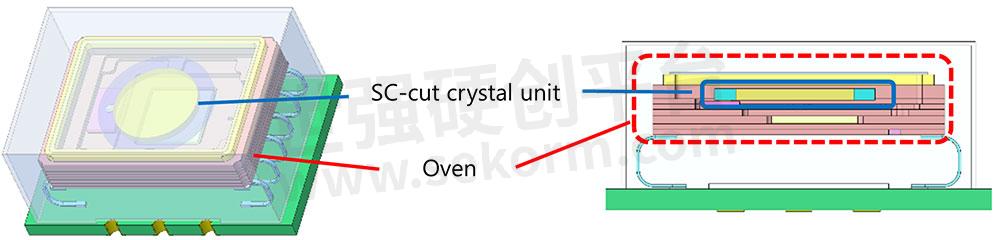

This improvement was enabled in large part by the miniaturization of the oven and the stress compensated (SC) cut crystal unit.

Internal structure of a conventional OCXO (conceptual image)

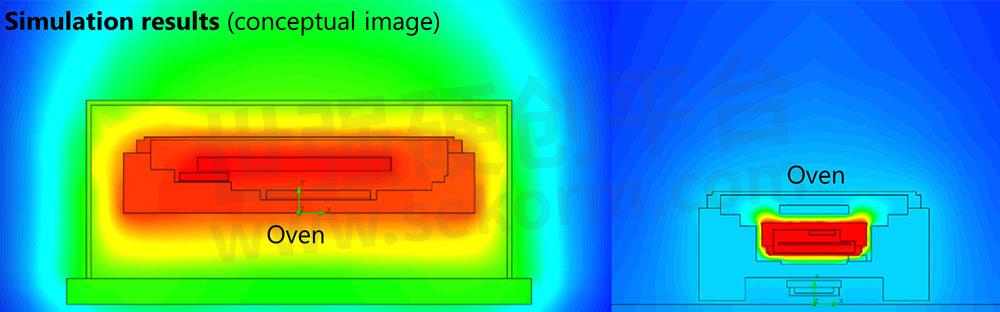

Unlike AT-cut crystal units3 used in ordinary crystal oscillators, SC-cut crystal units are highly stable and resistant to thermal shock and vibration. Earlier products employed a circular SC-cut crystal unit with a diameter of 6mm, requiring a large oven and a large amount of power to maintain a constant temperature. To solve this problem, Epson redesigned the crystal unit, using a rectangular structure instead of a circular one. Not only did they succeed in reducing the size of the SC-cut crystal unit by 90%, they did so while improving performance and reducing power consumption. The redesign also reduced the cubic volume of the oven by 96% compared to the earlier products.

Another challenge the developers faced was to achieve a low-power oven structure. Epson developed and optimized its own oscillator IC and heater IC to hold the SC-cut crystal unit in the oven at a constant temperature while minimizing power consumption. The oven is bonded inside the OCXO package with an adhesive that has low thermal conductivity to improve internal insulation. This limits the loss of heat from the heater IC and keeps power consumption low. By using a digital means of controlling the temperature of the SC-cut crystal unit instead of the conventional analog method, the developers were able to keep the crystal unit's temperature more stable even when the ambient temperature fluctuates, reducing the frequency/temperature characteristics of the OCXO from ±50 × 10-9 to ±3 × 10-9.(4)

Earlier products: 0.43W at 25℃, Developmental product: 0.2W at 25℃

These developments have resulted in a highly accurate OCXO that consumes 56% less power (0.2W at 25℃) than the earlier products and is 85% smaller (7.0 × 5.0mm size). This reduction in power consumption enables the temperature of the SC-cut crystal unit to stabilize faster, reducing frequency stability at startup by a factor of 5 or more compared to the earlier products.

Developmental product (conceptual image)

Samples of the new OCXO will be available from April 2025.

Epson plans to present a talk on the technology developed for the new OCXO at The International Timing and Sync Forum (ITSF 2024). The forum, of which Epson is a gold sponsor, is to be held in Spain from November 4 to 7.

As a leader in crystal devices, Epson will continue to provide crystal device products that meet the needs of all manner of electronic devices and social infrastructure.

New Product Features

Low power consumption: 0.2W at 25℃(still air)

Small size: 7.0 × 5.0 × 3.3mm, Typ.

Frequency/temperature characteristics: ±3 × 10-9

Startup time until Frequency stabilizes to within ±20 × 10-9:30s.

A PLL5 function allows the output frequency to be set anywhere from 1MHz to 170MHz through internal IC settings.

A jitter reduction function controls PLL induced noise deterioration.

The International Timing and Sync Forum (ITSF)

The world's largest time synchronization-themed forum brings together industry professionals from around the world for three days of lectures, solution exhibits, and networking. Speakers will include luminaries from end users, operators, and equipment vendors, who will present the latest advances and challenges of time synchronization solutions in a variety of industries.

Main Specifications of the New Product

1Epson's OG1409 series of OCXOs (now discontinued)

2Oven: A device designed to maintain the inside of the chamber at a certain constant temperature

3AT-cut crystal unit: A crystal resonator with a crystal chip produced from a rough crystal cut at a specific angle known as the AT cut. It covers the megahertz (MHz) band and is the most popular type of quartz crystal in use. AT-cut crystals have a frequency/temperature characteristics of a cubic function with a zero-crossing point near room temperature, so they provide excellent temperature characteristics.

410-9 means one part per billion, and ±10 × 10-9 is also commonly referred to as ±10 ppb.

5PLL: Abbreviation for phase locked loop, an electronic circuit that produces a desired output frequency to match a clock signal of a specific frequency.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.