Minebea Built New Facility for Defense-related and Aerospace Components at Its Matsuida Plant

June 4, 2012

Minebea Build New Facility for Defense-related and Aerospace Components at Its Matsuida Plant

Minebea Co., Ltd. built a new production facility as part of its strategy to expand operations geared toward the defense and aerospace markets. The new facility, with a total floor area of 9,000㎡, was constructed on the premises of Minebea's Matsuida Plant in Annaka, Gunma Prefecture. Minebea's plans also included closing its Omori Plant in Tokyo due to a lack of sufficient space.

Background

Minebea produced special aircraft and vessel components for the Ministry of Defense, special motors and actuators for commercial aircraft, as well as brushless motors, high-pressure blowers, electromagnetic clutches, and brakes for industrial equipment at its Special Device Business Unit's Omori Plant. Among these product lines, demand had been steadily soaring for aerospace industry products, primarily for domestic rocket and new aircraft model applications. This growing trend required Minebea to enhance development and production capacity to meet future demand. Located in a largely residential area, the Omori Plant, with its aging facilities, lacked adequate space for expansion. In light of these circumstances, Minebea decided to build a new facility dedicated to manufacturing products for the defense and aerospace industries on the premises of its more spacious Matsuida Plant and transfer the operations of the Omori Plant there. Minebea planned to move the Omori Plant's R&D and production operations for industrial equipment parts and components to its Fujisawa Plant in Kanagawa Prefecture with an aim to develop more advanced products through enhanced cooperation with the engineering department of the EMS and Measuring Components Business Units.

Overview and Purpose of the New Facility

The Matsuida Plant was located near the company's Karuizawa Plant, the main production hub for Minebea's machined components business, which was also home to the company's headquarters. This proximity provided Minebea easy access to the Karuizawa Plant's resources for use in operations at the new facility. The Karuizawa Plant was equipped with the precision machining technology needed for processing special materials used in aircraft and space equipment. The Special Device Business Unit's signature ability was that it could integrate a world of technologies, including mechanics, electronics, air and gas pressure, as well as control technologies, into a single reliable product. Combining these strengths enabled Minebea to further expand its defense-related and aerospace components business operations.

New plant construction schedule

Construction started in October 2012 The completion was in October 2013.

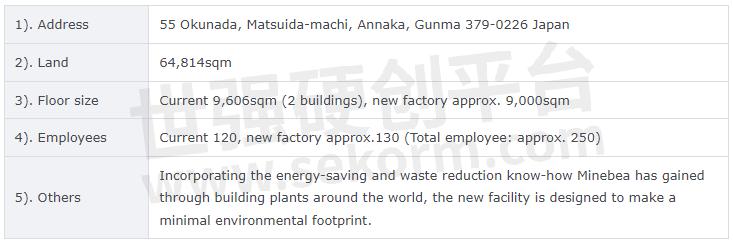

Outline of Matsuida Plant

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.