Read What Is An Industrial Gateway

In the broad blueprint of Industrial Internet of Things, IIoT, Industrial gateways serve as key hubs and play a bridge role in connecting the physical world with the digital world. This article will explore the definition, function, importance and application of industrial gateways in an in-depth manner from a professional perspective. It aims to provide comprehensive understanding and guidance for people who need networking applications.

1、What Is An Industrial Gateway

Industrial gateway, also known as network connector or protocol converter, is a key device that connects industrial field devices with the Internet or other network systems. It can not only realize data collection, conversion and transmission but also has various functions such as communication, security and management. It is an indispensable part of the industrial Internet of Things system. Through industrial gateways, various industrial equipment, sensors, and control systems can be seamlessly connected to the Internet to achieve remote monitoring, data analysis, and intelligent control.

Fig.1

2、The Core Function of The Industrial Gateway

2.1 Equipment Connection And Data Acquisition

The primary task of an industrial gateway is to connect various devices on the industrial site, such as sensors, PLCs, and meters, and collect real-time operational data and status information from these devices through wired or wireless means. These data may come from devices of different manufacturers and follow different communication protocols. Industrial gateways need to have strong compatibility and flexibility to adapt to various device interfaces and communication standards.

2.2 Protocol Conversion And Data Processing

Due to the wide variety of industrial field devices and complex communication protocols, industrial gateways need to parse and convert these raw data into a unified format and standard. This process includes multiple steps such as data cleaning, filtering, aggregation and format conversion to ensure the accuracy and consistency of data in subsequent processing and analysis. At the same time, industrial gateways can also perform preliminary processing and analysis on data, such as data compression and encryption, to improve the efficiency and security of data transmission.

2.3 Data Transmission And Communication Management

The processed data needs to be transmitted over the network to remote business systems or cloud platforms for further processing and analysis. The industrial gateway supports multiple communication methods, such as Ethernet, WiFi,4G,5Getc.Choose the most suitable one according to actual needs. During data transmission, the industrial gateway will perform communication management to ensure real-time, accurate and secure data. This includes establishing reliable communication connections, performing checksum and retransmission for data transmission, implementing security measures such as data encryption and authentication.

2.4 Edge Computing And Intelligent Processing

With the development and popularization of Internet of Things technology, edge computing has become one of the important functions of industrial gateways. Edge computing allows data processing and analysis to be performed locally on industrial gateways, reducing the dependence on remote systems and the need for transmission bandwidth. The industrial gateway can perform preliminary processing and analysis on the collected data according to preset rules and algorithms, such as data aggregation, threshold judgment, anomaly detection, etc., and upload the results of this processing to remote systems. This processing method can greatly improve the response speed and real-time performance of the system, while reducing the processing pressure and cost of remote systems.

Fig.2

3、The Role of Industrial Gateway

3.1 Realize Equipment Interconnection

As a bridge between different devices, industrial gateways enable the interconnection of industrial field equipment. By adapting to the communication protocols and interfaces of various devices, industrial gateways can connect devices from different manufacturers and models to form a unified data network. This allows enterprises to deploy and manage industrial field devices more flexibly, improving production efficiency and management level.

3.2 Maximizing The Value of Data

The industrial gateway converts data from the industrial field into valuable information resources through functions such as data collection, processing and transmission. These data can be used for real-time monitoring of production processes, optimizing resource allocation, predicting equipment failures and many other aspects. By deeply mining and analyzing these data, enterprises can discover potential problems in the production process and solve them in time to improve product quality and production efficiency. At the same time, these data can also provide support for enterprise decision-making and help enterprises formulate more scientific and reasonable business strategies and development plans.

Fig.3

3.3 Ensure The Security And Stability of The System

The industrial gateway has built-in security measures such as firewalls and encryption technology to ensure the safety and stability of data transmission. Through access control, identity authentication and other means, the industrial gateway can prevent unauthorized access and attacks to protect the industrial field equipment from network threats and attacks. In addition, the industrial gateway can also monitor and diagnose equipment status in real time, find and deal with equipment faults and problems in a timely manner to ensure stable operation of production systems.

3.4 Support Remote Monitoring And Management

The industrial gateway supports remote monitoring and management functions, and users can remotely view the device status and data information on the industrial site through the Internet. This allows enterprises to manage industrial field equipment more conveniently, reducing on-site maintenance costs and labor input. At the same time, industrial gateway also supports remote upgrade and configuration functions, which can realize remote update and maintenance operations of equipment to improve management efficiency and response speed.

3.5 Promote Intelligent Manufacturing And Operation&Maintenance

As an important part of the industrial Internet of Things, Industrial Gateways are significant in promoting intelligent manufacturing and intelligent operation and maintenance. By connecting industrial field devices and remote business systems or cloud platforms, the industrial gateway achieves real-time transmission and sharing of data. This allows enterprises to build intelligent manufacturing systems, enabling automation, intelligence and visualization of the production process. At the same time, industrial gateways can also provide support for intelligent operation and maintenance. By using real-time monitoring and data analysis methods to detect and handle equipment failures and problems in a timely manner, they improve operational efficiency and device reliability.

4、Classification of Industrial Gateways

4.1 Dimension of Communication Mode

● Ethernet industrial gateway: Connecting industrial equipment and networks through wired Ethernet.

● General wireless GPRS industrial gateway: uses GPRS wireless communication technology for data transmission.

● WiFi industrial gateway: Connecting devices and transmitting data via the WiFi wireless network.

● 4G industrial gateway: Based on 4G mobile communication network, it provides higher speed and more stable data transmission capabilities.

● Narrowband IoT NB-IoT industrial gateway: designed specifically for the Internet of Things, supporting low power consumption and wide coverage narrowband communication.

● Long-distance wireless communication LORA industrial gateway: suitable for long distance, low power consumption of wireless data transmission.

4.2 Forwarding Protocol Dimension

● ModbusRTU industrial gateway: support data forwarding of the Modbus RTU protocol.

● Modbus TCP industrial gateway: supports data forwarding of the Modbus TCP protocol.

● OPC UA industrial gateway: supports data transmission of the OPC UA open platform communication unified architecture protocol.

MQTT industrial gateway: Based on the MQTT message queue telemetry transmission protocol, it achieves lightweight data exchange.

● HTTPS industrial gateway: Encrypts and transmits data through the HTTPS protocol to ensure data security.

● BACNET industrial gateway: Supports the BACNET building automation and control network protocol, used in intelligent buildings.

● IEC104 industrial gateway: it complies with the standard of IEC 60870-5-104 and is used for power automation communication.

4.3 Dimension of Collection Object

● Robot industrial gateway: dedicated to collecting information such as the operating status of robot controllers, alarm messages, and coordinate values for each axis.

● Industrial gateway for CNC machine tools: Collect information from the CNC system and machine tool, such as system status, operation mode, alarm information, etc.

PLC industrial gateway: collects data from various brands of PLC I/O, automation equipment and sensors.

● instrumentation industry gateway: collect data from digital instruments and various sensors.

4.4 Edge Computing Capability Dimension

● Transparent industrial gateway: no protocol packet parsing, only supports transparent transmission.

● Basic industrial gateway: supports data collection, protocol parsing, storage and forwarding, network disconnection and continuous transmission, remote control, etc.

● Edge computing industrial gateway: On the basis of the basic level, it adds functions such as edge computing, local alarm, edge control, etc.

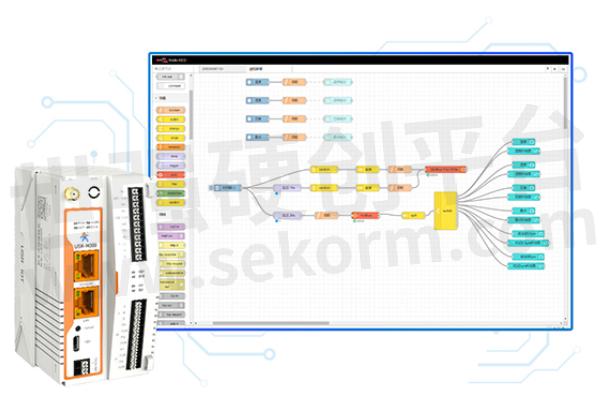

Fig.4

4G Global BandIO, RS232/485, EthernetNode-RED, PLC Protocol

4.5 Security Dimension

● Industrial security gateway: Provides security protection functions such as firewalls and encrypted transmission.

● Boundary isolation industrial network barrier: to achieve physical or logical network isolation and enhance system security.

4.6 Application Industry Dimension

● Communication management machine for the power industry: dedicated to communication management in the power industry.

● Petrochemical functional safety remote terminal unit RTU: used for remote monitoring and control in the petrochemical industry.

● Intelligent building BACnet gateway: applied in the field of intelligent buildings, supporting BACNET protocol.

4.7 Dimension of Acquisition Interface

● Collection gateway: focuses on data collection functions and has multiple data collection interfaces.

● Protocol gateway: It focuses on protocol conversion functions and can support multiple industrial protocols.

5、Key Indicators of Industrial Gateway

5.1 Communication Capability

①. The protocol supports diversity

The industrial gateway should support multiple industrial communication protocols, including but not limited to Modbus, OPC UA, MQTT, HTTPS, IEC 60870-5-104, and others. The extensive protocol support capability ensures that the gateway can communicate with devices of different manufacturers and models, achieving seamless data access.

②. Communication rate and stability

The communication rate of the gateway directly affects the real-time performance of data transmission. High-speed communication rate can reduce the delay of data transmission and improve the response speed of the system. At the same time, communication stability is also crucial. The gateway should have strong anti-interference capabilities and self-recovery mechanisms to ensure continuous and stable operation in complex industrial environments.

③. Modular design

In order to adapt to the needs of different application scenarios, industrial gateways usually adopt a modular design. This design allows the gateway to flexibly configure different communication modules, processing modules or security modules according to actual needs. Users can customize according to project requirements, which not only meets functional requirements but also reduces costs.

5.2 Data Processing Capability

①. Accuracy and Range of Data Collection

The industrial gateway should have high-precision data acquisition capabilities, which can accurately capture the running status and parameter changes of field equipment. At the same time, the gateway should also support a wide range of data acquisition, including analog, digital, pulse and other types of data.

②. edge computing capability

Edge computing is one of the important characteristics of modern industrial gateways. The gateway should have the ability to perform data processing and analysis locally, in order to reduce dependence on cloud-based systems and lower data transmission latency. The edge computing function can include data aggregation, threshold judgment, anomaly detection, etc., providing a strong basis for subsequent decision support.

5.3 Safety Performance

①. Data Security

The industrial gateway should have strong data encryption and transmission security mechanisms to ensure the confidentiality, integrity, and availability of data during transmission. This includes using secure communication protocols such as HTTPS, TLS/SSL, implementing data encryption measures such as AES and RSA, and establishing a secure access control policy.

②. Equipment safety

The gateway itself should also have high security performance, including preventing unauthorized access, resisting network attacks such as DDoS attacks and SQL injections, and enabling remote management and secure upgrades of devices. In addition, the gateway should also support security authentication and authorization mechanisms to ensure that only legitimate users can access and operate devices.

5.4 Reliability And Stability

①. Redundant design and fault tolerance

The industrial gateway should have redundant design and fault tolerance capabilities to ensure that the system can automatically switch to a standby state and continue running when a single component or module fails. This includes power redundancy, communication link redundancy and fault tolerance mechanism at software level.

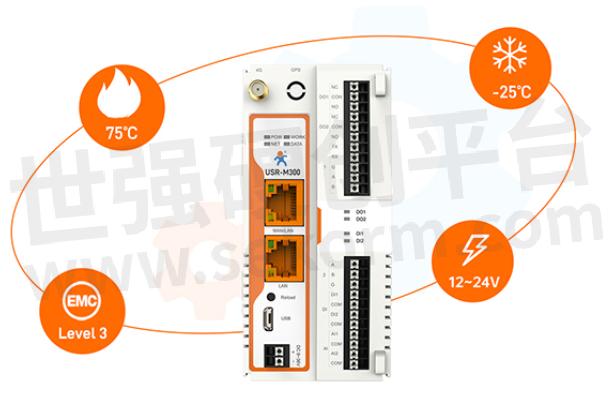

②. Environmental adaptability

Industrial gateways are usually deployed in complex industrial environments, so they must have high environmental adaptability. This includes high temperature resistance, low temperature resistance, dust and waterproofing, shock resistance and impact resistance to ensure stable operation in harsh environments.

Fig.5

5.5 Ease of Use And Maintainability

①. User-friendly interface

The industrial gateway should provide intuitive and easy-to-use user interface (UI) and configuration tools, so that non-professional users can easily complete device configuration and management tasks. At the same time, the gateway should also support remote configuration and upgrade functions to reduce on-site maintenance costs and labor input.

②. Fault diagnosis and self-recovery capability

The gateway should have strong fault diagnosis and self-recovery capabilities, capable of automatically detecting and repairing common faults. In addition, the gateway should also provide detailed logging and alarm functions so that users can detect and handle potential problems in a timely manner.

5.6 Extensibility And Compatibility

①. Expansion interface and module

The industrial gateway should provide a rich set of expansion interfaces and module options to meet the needs of different application scenarios. For example, adding new communication modules, processing modules or security modules to improve the flexibility and adaptability of the gateway.

②. Compatibility testing and certification

The gateway should undergo rigorous compatibility testing and certification during the design and production process to ensure compatibility with devices of different brands and models. This helps reduce the difficulty and cost of system integration, improving overall performance and stability.

Fig.6

6、Why Is The Industrial Gateway So Important

6.1 Bridge for Realizing Equipment Interconnection

There are many types of equipment in the industrial field, and communication protocols vary. This poses a huge challenge to interconnection between devices. As an intermediate layer device, the industrial gateway has strong protocol conversion and adaptation capabilities, which can uniformly process and transmit data from different devices and protocols. Through industrial gateways, enterprises can easily achieve interconnection between devices, break information silos and build a unified Industrial Internet of Things system.

6.2 Improve The Efficiency of Data Collection And Processing

In the industrial Internet of Things, data collection is the first and most important step. Industrial gateways can collect various data in real time and accurately, including equipment operating status, production parameters, environmental information, etc. At the same time, industrial gateways also have preliminary data processing capabilities that can filter, compress and encrypt collected data to improve efficiency and security of data transmission. Through the data acquisition and processing capabilities of industrial gateways, enterprises can more efficiently obtain information from production sites to provide strong support for subsequent decision analysis and optimization.

6.3 Ensure The Security And Reliability of Data Transmission

In the industrial Internet of Things, security and reliability of data transmission are crucial. As a channel for data transmission, industrial gateways must have strong security protection and fault tolerance mechanisms. The industrial gateway supports multiple security protocols and encryption technologies, ensuring the confidentiality, integrity, and availability of data during transmission. At the same time, industrial gateways also have redundant design and fault tolerance mechanisms that can automatically switch to backup channels or devices in case of network failure or equipment malfunction, ensuring continuity and reliability of data transmission.

Fig.7

6.4 Promote The Upgrading of Industrial Automation And Intelligence

As an important part of the industrial Internet of Things, industrial gateways have promoted the upgrading of industrial automation and intelligence. Through industrial gateways, enterprises can achieve remote monitoring, fault diagnosis and predictive maintenance of equipment to improve production efficiency and equipment utilization. At the same time, industrial gateways can also be combined with advanced technologies such as cloud platforms and big data analysis to achieve intelligent management and optimization of production processes. The realization of these functions cannot be separated from the support and promotion of industrial gateways.

6.5 Promote The Digital Transformation of Industry

The digital transformation of industry is one of the important trends in current manufacturing development. As a bridge connecting the physical world and digital world, industrial gateways provide strong support for enterprises' digital transformation. Through the application of industrial gateways, enterprises can build a digitalized, networked and intelligent production system to achieve visualization, traceability and optimization in the production process. This can not only improve the production efficiency and product quality of enterprises, but also reduce production costs and energy consumption levels, promoting sustainable development.

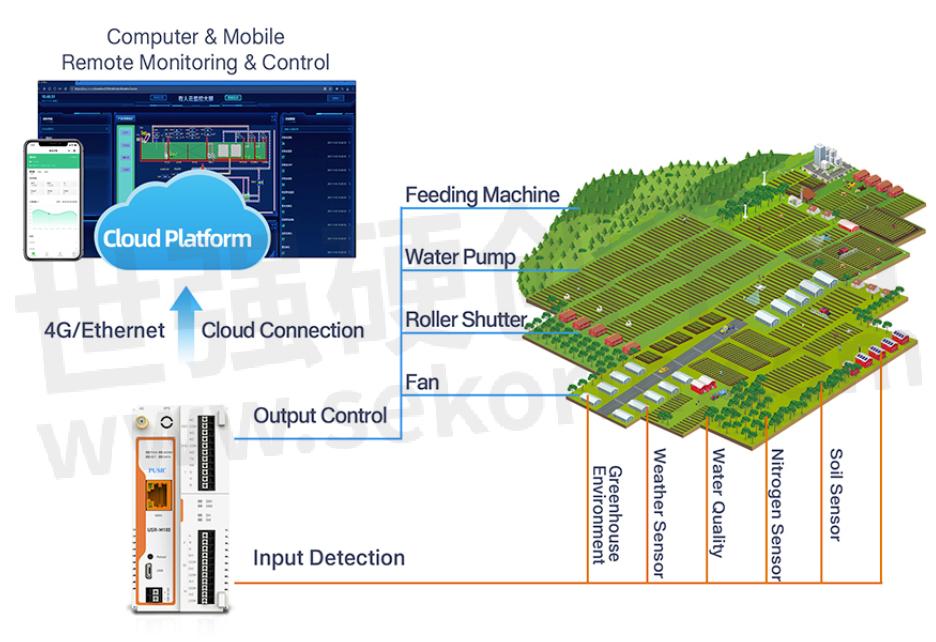

7、Application Cases of Industrial Gateway

7.1 Intelligent Manufacturing

①. Production line monitoring and optimization

In the field of intelligent manufacturing, industrial gateways can access various devices on production lines such as PLCs, sensors and robots to collect real-time production data and transmit it to cloud or local servers. Through the analysis and processing of production data, enterprises can monitor the operation status of their production lines in real time, identify and solve potential problems promptly, and improve production efficiency and quality. At the same time, industrial gateways can also support remote debugging and fault diagnosis functions to reduce on-site maintenance costs and time.

②. Intelligent warehousing and logistics

In the field of warehousing and logistics, industrial gateways can connect warehouse management systems (WMS) with logistics equipment such as AGVs and RFID tags to achieve real-time monitoring and automated inventory management. By collecting information such as the location, quantity and status of goods, enterprises can optimize inventory layout and logistics routes to improve storage efficiency and speed. In addition, the industrial gateway also supports remote scheduling and command functions, making warehousing and logistics processes more intelligent and efficient.

Fig.7

7.2 Energy Management

①. Smart grid

In the field of smart grid, industrial gateways can access various power equipment such as smart meters, transformers and circuit breakers to collect real-time power data and transmit it to the grid dispatching center. Through the analysis and processing of power data, the grid dispatching center can monitor the real-time operation status of the power grid, predict electricity demand, and optimize power distribution. At the same time, industrial gateways also support remote control and fault diagnosis functions to ensure safe and stable operation of power grids.

②. Renewable energy monitoring

Industrial gateways also play an important role in monitoring and managing renewable energy sources such as solar and wind power. By connecting to renewable energy generation equipment such as photovoltaic panels and wind turbines, the industrial gateway can collect real-time power generation data and transmit it to the monitoring center. The monitoring center can adjust the power generation strategy and optimize energy allocation according to the power generation data, improving the utilization rate of renewable energy sources and economic benefits.

Fig.8

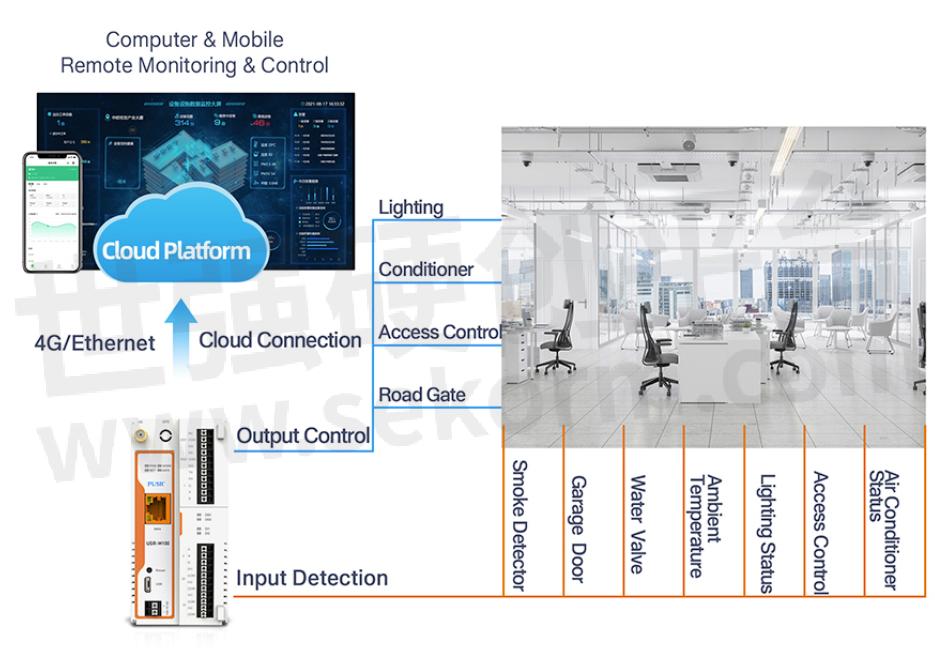

7.3 Smart City

①. Intelligent Transportation

In the field of smart cities, industrial gateways can be applied to intelligent transportation systems. By connecting to traffic lights, cameras, vehicle detectors and other equipment, the industrial gateway can collect real-time traffic data and transmit it to the traffic management center. The traffic management center can adjust the timing of signal lights, optimize traffic routes and release traffic information based on traffic data to alleviate traffic congestion and improve road capacity.

②. environmental monitoring

Environmental monitoring in smart cities is also one of the important application scenarios for industrial gateways. By connecting to air quality monitoring stations, water quality monitoring stations and other equipment, industrial gateways can collect environmental data in real time and transmit it to the environmental protection department. The environmental protection department can assess the quality of environment and formulate corresponding measures to protect urban ecological environment and residents' health according to environmental data.

Fig.9

7.4 Industrial automation

①. Remote control and monitoring

The field of industrial automation is one of the traditional application areas for industrial gateways. By connecting to various automation devices such as PLC and DCS, industrial gateways can achieve remote control and monitoring functions for equipment. Users can remotely access the device interface through the Internet and configure and manage it, reducing on-site operation costs and risks. At the same time, industrial gateway also supports real-time data acquisition and transmission functions to provide users with real-time monitoring capabilities of equipment operation status and performance parameters.

②. Distributed Control System

In the distributed control system (DCS), industrial gateways serve as communication hubs, connecting various control units such as programmable logic controllers (PLCs) and intelligent instruments to form a comprehensive control network. Through the communication and data processing capabilities of industrial gateways, DCS systems can achieve automated control and optimized management of complex process flows. At the same time, industrial gateways also support multiple communication protocols and interface standards, enabling DCS systems to interconnect and collaborate with devices from different vendors.

As an important part of the industrial Internet of Things, industrial gateways play an irreplaceable role in data collection, communication, security and management. With the deepening of Industry 4.0 and digital transformation, industrial gateways will be used more widely to bring smarter, automated and efficient changes to industrial production. For people who need to do networking applications, it will be an inevitable choice for them to deeply understand and master the relevant knowledge and technology of industrial gateways.

- +1 Like

- Add to Favorites

Recommend

- How to Choose a Cost-effective Ethernet to RS485 Converter?

- Why Is a 5G Cellular Router Faster Than a 2.4G Router ?

- Main Features of Edge Computing Gateway

- 5G CPE Configuration Webpage: Revolution and Solutions for Traditional Industries

- The Use of the Serial to Ethernet Converter in the Laser Cutting Machine Remote Monitoring System

- Does A Gigabit IOT Router Refer to Network Speed Or Broadband?

- 5G LTE Router Purchase Tips in The 5G Era: Speed, Coverage and Compatibility

- Industrial Gateway, IoT Gateway, and PLC Gateway: Bridge Connecting the Intelligent Future

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.