What Are Smart Batteries, and How Do They Work for Your Portable Devices?

What are smart batteries, and how do they work?

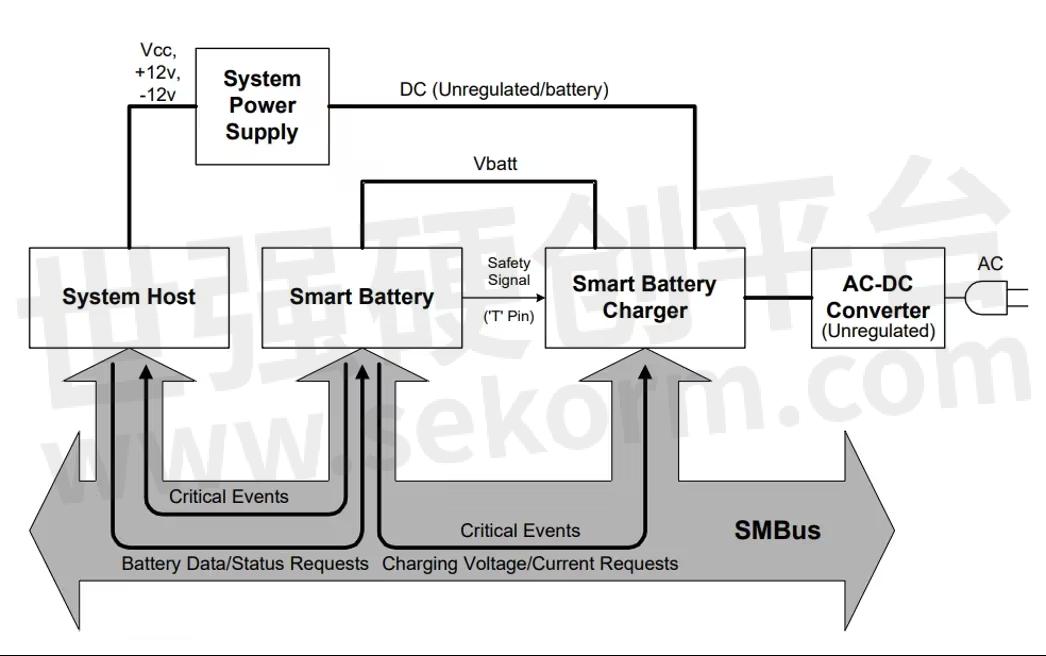

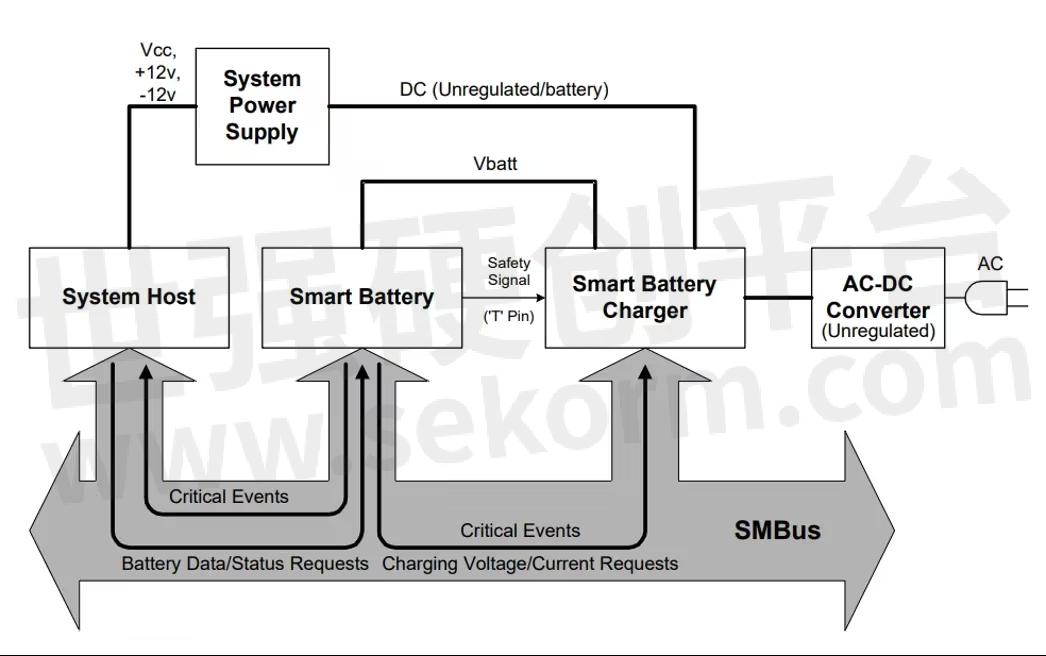

Smart batteries are designed to be integrated into portable devices as part of a wider “smart power management system.” This system typically consists of a smart battery, a smart charger, and a system management bus (SMBus) that communicates between the different components.

In a traditional portable device setup, any battery is just a “dumb” chemical power cell. Battery metering, residual capacity assessment, and any decisions about power usage are informed solely by readings “taken” by the host device. Such readings are largely guesswork, usually based on the voltage from the battery through the host device or readings taken from coulomb counters in the host.

However, in an smart power management system, the smart battery can highly accurately “tell” the host how much power it has left and how it wants to be charged.

Typically, the battery, smart charger, and host device communicate with each other to maximize product safety, efficiency, and performance. For example, an smart battery requests a charge only when needed rather than placing a constant, steady “drain” on the host system. As a result, smart batteries charge more efficiently.

The smart battery can also tell the host device when to shut down based on its assessment of remaining capacity, thus maximizing “runtime per discharge cycle.” This approach is far superior to typical “dumb” battery systems with fixed voltage cutoff.

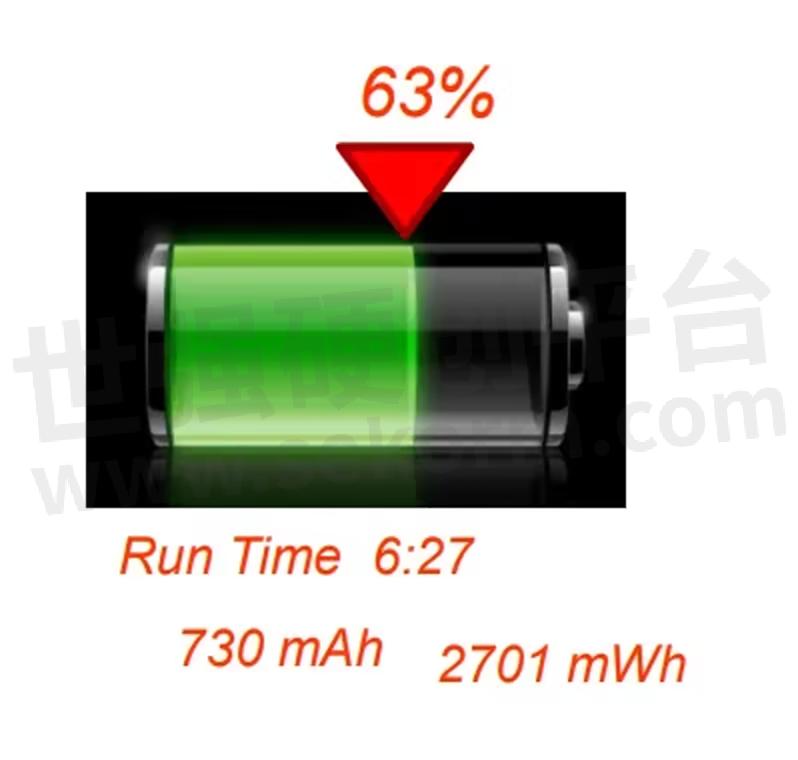

As a result, host portable systems using innovative battery technology can provide the user with accurate and meaningful runtime information. This is critical for critical equipment where power failures are unacceptable.

Measurement and real-time monitoring

Smart batteries constantly track their capacity, whether charging, discharging, or removing equipment. Battery capacity is reported in milliampere hours (mAh) with a resolution of 1 mAh. Actual capacity is reported in mAh and as a percentage (original design capacity and time since the battery was last charged).

Battery meters calculate changes in battery capacity based on various factors, such as temperature, charge rate, discharge rate, and so on. Smart battery meters also tend to be adaptive, adjusting dynamically as the battery ages and its chemistry and ability to hold a charge change.

As a result, smart batteries can often predict their capacity to within ±1% (compared to ±20% accuracy with “dummy” batteries).

Smart batteries can also modify their charging algorithms in response to changing environmental conditions, thus extending the life of the battery. If a battery is charged when it is very cold or very hot, it can be damaged. Therefore, the Smart Battery will reduce the charging current when the battery is warm to minimize the possibility of damage and stop charging altogether when the battery is unusually cold or unusually hot.

Standardized Communication and Future Advantages

Smart batteries maximize charging efficiency and safety by requesting their charging voltage and current from a compatible smart charger. This approach ensures that the battery is only charged at the most appropriate voltage and current when needed.

“SMBus (System Management Bus) and SBDS (Smart Battery Data Specification) compliant” means that the Smart Battery conforms to open standards that OEM device developers can easily access.

The SBS (Smart Battery System) specification and the accompanying SMBus specification were created by Duracell and Intel in 1994 and involved transferring battery information over a two-wire communications bus. Together with the SBCS (Smart Battery Charger Specification) and SBSMC (Smart Battery System Manager Specification), the SBS standard describes all of the information that can be communicated between a smart battery, charger, and host device.

Thanks to the continuous communication of their status, charging profiles, etc., smart power systems can future-proof a product’s power supply: If newer battery technologies are developed (e.g., with higher storage capacity and different charging methods), these new batteries can be “swapped out” without the need to replace the charger in the field. Existing chargers would receive different charging instructions from the battery and adjust accordingly.

This simple fact tends to make smart power systems more economical in the long run, especially in the case of costly medical equipment or where battery life is at its longest (e.g., in anesthesia workstations, ventilators, and remote patient monitoring) and the use of smart batteries minimizes the cost of re-development.

Ease of Integration

Interestingly, we’ve found that customers think they need to do a lot of R&D to get batteries to work in their systems.

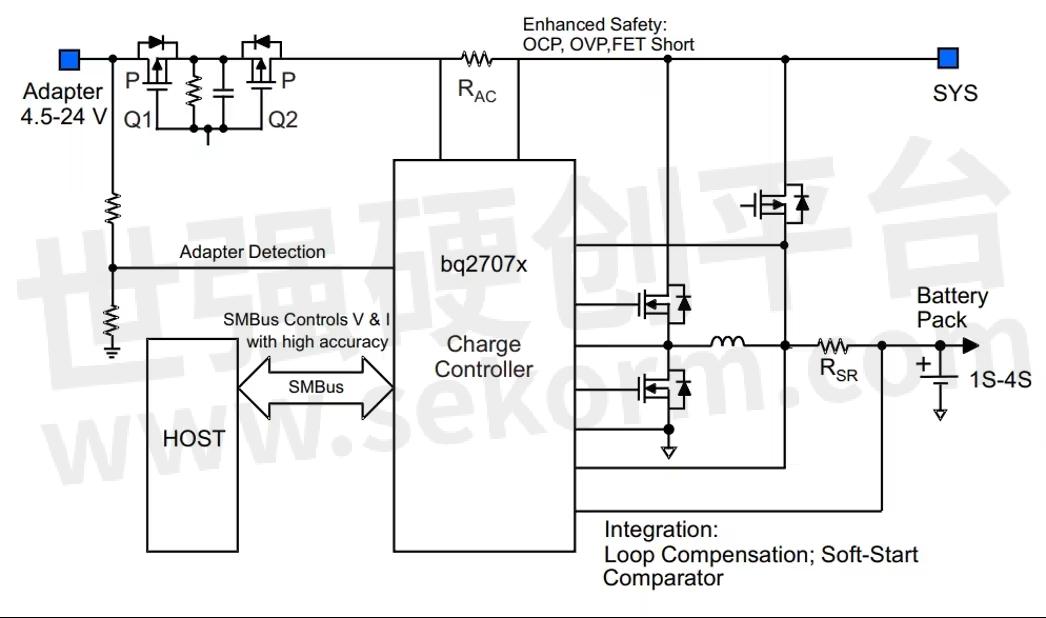

However, electronic component manufacturers such as Texas Instruments (TI) and Linear Technology have provided excellent, highly reliable, and highly integrated reference designs for their Smart Chargers and power management ICs. These reference designs make the integration of smart batteries very easy. In addition, the openness of the various communication protocols makes it easy for device software engineers to query the battery and extract useful information such as remaining capacity, remaining runtime, cycle life, and more.

Smart Chargers

Despite the increased cost of batteries, smart batteries and smart charging systems offer the right choice for many portable devices, with clear advantages in terms of longevity, charging, safety, and long-term value.

The market for smart charging systems is now quite mature. However, designers often need to pay more attention to options for implementing smart charging systems. In addition, the battery life and adaptability designers can expect from a given smart power technology are always changing. For this reason, we always recommend that designers work with a reliable third-party battery expert to ensure they specify the most appropriate smart charging solution for their device.

SMBus Communication FAQs

1. Checksum: The battery comes with a PSE checksum bit by default; if there is data corruption or data loss, the host can complete the checksum through the checksum bit, filtering out erroneous data in real-time current and average current. The last bit, 0x01, is the PSE check bit; the host can calculate the data obtained in front of the PSE (CRC-8 C(x) = x8 + x2 + x + 1) to get the check bit and compare whether it is the same as the check bit delivered by the battery.

2. Current reading conversion: Battery current distinguishes the battery charging and discharging state by +/-, discharging current is -, read as a signed number.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.