WACKER’s SILRES® BS 6920 Silane-terminated Binder Provides A Reliable Protection from Stains and Wear for Concrete Floors

Flawless Every Step of the Way

Concrete floors are chic, but sensitive: Impregnation with SILRES® BS 6920 provides reliable protection from stains and wear, and makes the surface more aesthetically pleasing.

Concrete floors have changed their image in the last 30 years. Though formerly preferred in garages, warehouses and factory halls, they gained a place in modern interior design in the 1980s: high-quality concrete and cement-bound flowing-screed flooring that has been ground and polished is now considered chic. It adorns exhibition and retail areas, shopping arcades, bistros and museums. Even developers of exclusive residential areas have been won over by the unadorned elegance of a concrete flooring in kitchens and living rooms.

A Hard Appearance, but Sensitive Inside

However, concrete flooring and cement-bound screeds and less abrasion resistant than they appear due to their porous surface. When subject to foot or wheel traffic, concrete floors shed material, which is later deposited as dust on nearby objects. When heavily stressed for longer periods, the flooring even becomes fragile. As a result of its porosity, the unprotected surface also absorbs spilled drinks, engine oil or other fluids. The result is ugly marks that cannot be removed.

Protection against Abrasion and Marks

To prevent this, concrete and screed floors are protected against soiling and abrasion. The chemical industry has developed a range of impregnation agents for this purpose. Water-based systems based on silicates and solvent-based impregnating agents that are based on silane are widely used. During impregnation, liquid preparations penetrate deep into the open pores and fill them partially or entirely. Once the agent has solidified, liquid substances cannot soak into the treated surface. It is better if they can simply be wiped off without trace.

Many Agents Are Pushed to Their Limits

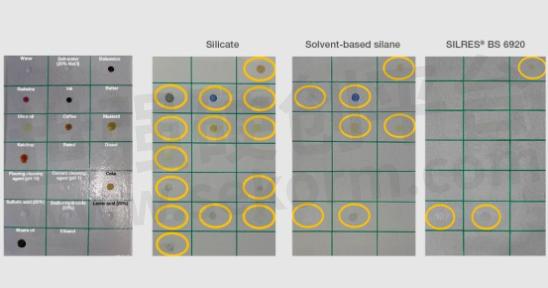

However, day-to-day soils push many impregnation agents to their limits: WACKER chemist Dr. Udo Anders has tested some commercial concrete floor impregnation agents and ascertained that silicate-, and even silane-based agents only provide very limited stain protection in many applications - even for day-to-day soiling materials. What use is an impregnation that cannot deal with ketchup, mustard, red wine or cola? Despite impregnation, it is difficult to remove such stains and keep the floor looking like new. What is more, for toxicological and environmental-protection reasons, the construction industry is striving to avoid solvent-based systems.

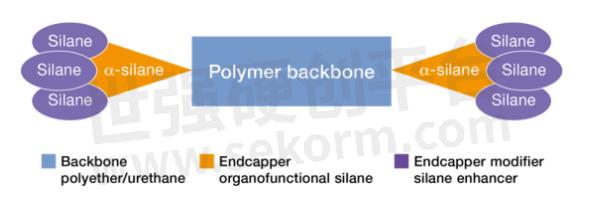

The Solution is Protection with Alpha-Silane

Dr. Udo Anders offers the answer with SILRES® BS 6920. The binder for impregnating concrete is based on WACKER’s alpha-silane technology, and combines outstanding soiling resistance with high mechanical strength. As with all silane-terminated polymers, SILRES® BS 6920 is crosslinkable: exposure to moisture triggers the formation of a siloxane network. Due to WACKER’s own alpha-silane technology, all that is needed is the presence of an aminosilane catalyst to ensure that crosslinking proceeds fast enough.

Close-Meshed Network

WACKER developers have custom-designed the new polymer for use in concrete impregnating agents. For example, the silane building blocks were modified so that SILRES® BS 6920 cures to form a particularly close-meshed network of quartz-like structural units. The length of the polyether chains was also adjusted. These optimization measures mean that the viscosity of the new binder is as low as olive oil. The binder penetrates deep into the pores of the concrete floor, fills them and cures to form a hard material. Water- or oil-based fluids can no longer penetrate into the treated floor, and cause a permanent color change even if they are wiped off over the course of the day. The mechanical reinforcement of the substrate increases the abrasion resistance at the same time. If the surface is exposed to high levels of UV radiation, the chemists recommend using the SILRES® BS 6920-based impregnating agent with UV stabilizers.

Tests have shown that SILRES® BS 6920 offers substrates effective protection against even stubborn soiling agents. Even after several hours, red wine, coffee, and oil can be wiped off without leaving any stains.

“SILRES® BS 6920 enables the construction industry to easily produce one-component impregnating agents with high scrub resistance for concrete and screed floors.”

Dr. Udo Anders

Diverse Possibilities

“SILRES® BS 6920 makes it possible for the construction industry to easily produce one-component impregnating agents that exhibit high scrub resistance for concrete and screed floors,” says Dr. Udo Anders The binder itself is solvent-free and can also be further processed without additives due to its low viscosity. But it can be diluted with solvents if needed. It is now possible to produce transparent impregnating agents that give concrete floors a glossy and polishable surface finish, even on rough surfaces. However, formulators can also mix in matting agents, pigments or reinforcing fillers and then reduce the viscosity by adding a solvent. In this way, the preparation produces a thin coating with a matt surface.

Easy to apply

It’s also a cinch to apply the impregnation agents: they are one-component and can be applied with a mop or roller, or sprayed on with an airless spray gun. For highly porous and absorbent flooring, it is advisable to apply two coats. With the first coat, the agent soaks into the floor; the second coat reduces the surface roughness by film-forming, with the film typically having a thickness of about 50 to 100 grams per square meter. You can walk on the floor after twenty-four hours and – if required – polish it.

Effective Stain Protection

Yet the most impressive feature is the anti-staining properties achieved by impregnation with SILRES® BS 6920. In his Burghausen lab, Dr. Anders has compared the stain protection of SILRES® BS 6920 on cement-bound test plates with the effect of impregnating agents based on silicates or silanes. The result is clear: in the case of the silicate impregnation, fourteen of the twenty test substances left permanent stains; in the case of silane impregnation, it was seven, and in the case of SILRES® BS 6920, only three.

“SILRES® BS 6920 is therefore the binder of choice when dealing with heavy stress from food, tire marks, foot traffic or vehicle traffic and the flooring needs to remain easy to clean,” adds marketing manager Udo Goedecke. The application possibilities of impregnation agents produced with this silane-terminated binder range from parking garages, car repair shops, train stations, and logistics centers, through showrooms, catering facilities, and event and convention centers to museums and residential buildings.

Floor Surface Treatment

Impregnation

Solid, porous materials are

saturated with dissolved,

emulsified or dispersed

substances. The pores are filled

either partially or completely.

Coating

A thin coating is applied to

materials to prevent substances

from entering or escaping. Pores

are not filled, even if there are

several layers.

Concrete Impregnation

According to the EN 1504-2 standard, concrete impregnation is a treatment that partially or totallfills the pores of the concrete. Depending on the absorbency of the concrete and the quantity of the preparation used for the treatment, an ultrathin, non-uniform film also forms on the concrete surface. In comparison, the term coating applies if the treatment agent does not penetrate the pores and – instead of filling the pores – lies on the surface, bonds strongly and forms a sealed, thick film that also covers the pores. The film thickness of a coating is normally between 0.1 and 5.0 millimeters. Impregnations are generally produced using no-solids formulations based on SILRES® BS 6920. Adding solids stops the formulation from penetrating deeply into the pores, producing a thin coating.

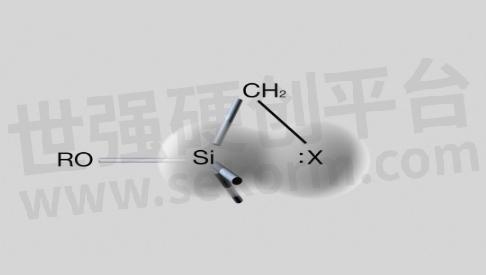

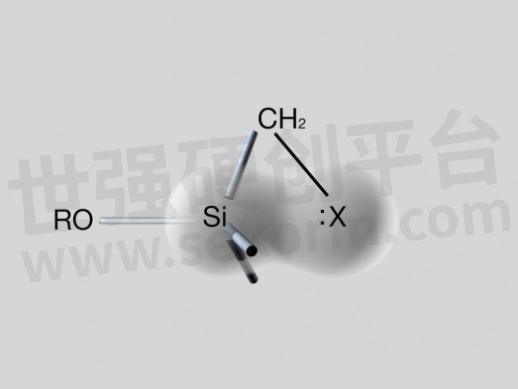

WACKER’s alpha-Silane Technology

In the early 2000s, WACKER developed organofunctional alkoxysilanes that could couple to organic polymers and were also characterized by an exceptionally high reactivity to moisture. The reason for the reactivity lies in the structure of these silanes: one of the four binding partners of the silicon atom is a nitrogen-containing organic group, whose nitrogen atom is bound to the silicon atom via a methylene bridge. This short bridge creates precisely the distance needed between the two atoms for the nitrogen atom to facilitate release of the alkoxy groups from the silicon atom, thereby accelerating the reaction with water molecules. Silanes of this type are called alpha-silanes – in contrast to those containing the significantly longer propylene bridge, the so-called gamma-silanes. The reaction-accelerating effect is so great in the alpha-silanes that they react about 100 to 1,000 times faster than the corresponding gamma-silanes.

This high reactivity is not even affected when the alpha-silane is coupled to an organic polymer. For the alpha-silane-terminated polyethers WACKER has already performed the coupling, rendering the polymer crosslinkable: the reaction with moisture produces a siloxane network. However, WACKER also offers alpha-silanes that are not bound to a polymer. At WACKER, “alpha-silane technology” refers to the company’s entire product portfolio of alpha-silanes and alpha-silane-terminated polymers as well as its extensive chemical-technical expertise concerning these compounds.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.