Crystals:the First Choice for Automotive Domain Controllers

As the core component of the automotive domain controller, the crystal works with other components to ensure the stable operation of the domain controller. Especially in high and low temperature conditions, its stable vibration characteristics are crucial to ensure the normal operation of automotive electronic systems.

What is Automotive Domain Controller?

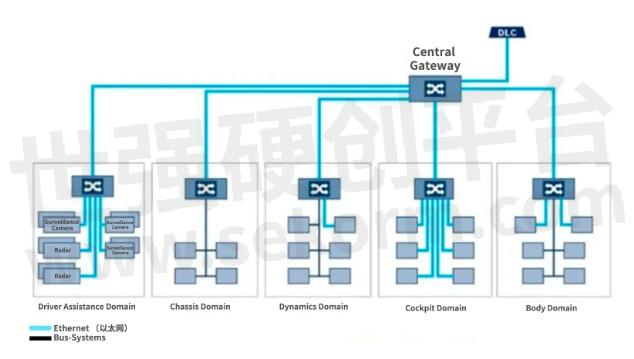

Automotive domain controller is a new type of automotive electronic controller, which divides the functions of each part of automotive electronics into several domains, such as power transmission domain, body electronics domain, assisted driving domain, etc., and then utilizes a powerful multi-core CPU/GPU chip to control most of the functions originally belonging to each ECU in the domain in a relatively centralized manner, so as to solve the growing development needs of vehicle electronics.

Domain controller enables the vehicle to have multi-sensor fusion, localization, path planning, decision-making and control capabilities, usually requires external multiple cameras, millimeter-wave radar, lidar and other equipment to complete the functions include image recognition, data processing, and so on. The crystal can provide a stable clock frequency to ensure that the communication between each module is carried out accurately.

Crystals requirements for domain controllers

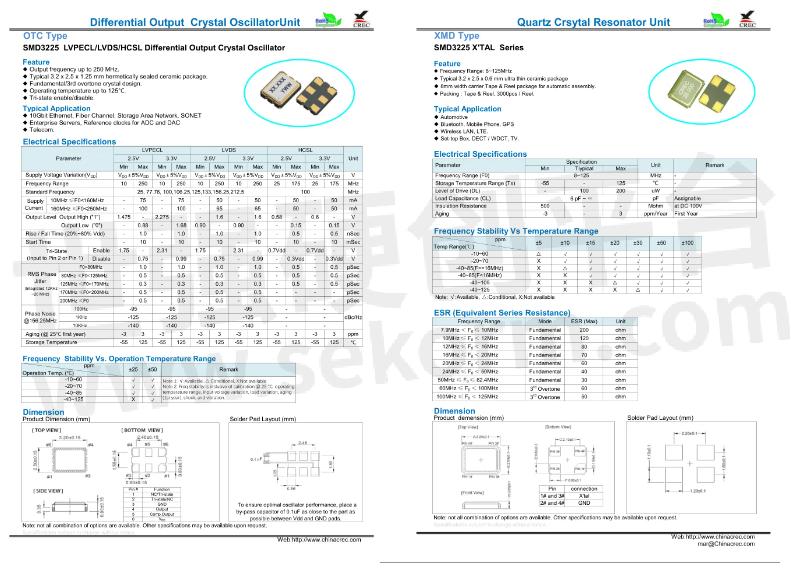

Crystal selection requirements: high precision, high stability, small size, anti-vibration, shock resistance, high temperature resistance, etc.

Main models: 3225, 2016, 3215

Commonly used frequency points:

① Passive crystal oscillator: 12M, 16M, 20M, 24M, 25M, 26M, 27M, 30M, 40M, 100M, 125M, 32.768KHZ

②Active crystal: 1.8-3.3V

The importance of crystal in the domain controller

Due to the large number and complexity of electronic devices in automotive domain controllers, a large amount of electromagnetic interference (EMI) and radio frequency interference (RFI) is generated. These interferences may affect the normal operation of the system and even lead to malfunctions or safety hazards.

As the core component of the automotive domain controller, the crystal works with other components to ensure the stable operation of the domain controller. Especially in high and low temperature conditions, its stable vibration characteristics are crucial to ensure the normal operation of automotive electronic systems. In addition, it meets the high temperature reflow profile requirements for lead-free soldering and complies with the AEC-Q200 standard.

- +1 Like

- Add to Favorites

Recommend

- CREC Joins Electronica China 2024

- Spread Spectrum Crystals of CREC: The First Choice for Stable Operation of Automotive Electronics

- Companies Focusing on the Localization of High-End Automotive-Grade Crystal Oscillators——CREC

- What Batteries Are Used In OTC Hearing Aids?

- Prescription vs OTC Hearing Aids: What‘s the Difference?

- The Nidec Group’s Four Machine Tool Companies to Exhibit Products at CCMT2024 as Comprehensive Machine Tool Manufacturers to Meet All Industrial Fields’Needs

- Nidec Executes MOU with Taiwan’s MIRDC to Promote the Use of Energy- and Electricity-saving High-efficiency Industrial Motors

- OLE WOLFF Drivers Smaller Than 5mm are Ideal for Applications Where Space is Limited and Precision is Required

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.