A Comprehensive Guide to Using Terminal Connectors

Terminal Connectors are an indispensable component in electrical connections, utilized to establish secure connections between wires, ensuring stable transmission of electrical current or signals. This article will provide a detailed explanation of the usage of terminal connectors, aiding readers in better understanding and applying this electrical component.

I. Overview of Terminal Connectors

Terminal connectors are typically constructed from conductive materials such as copper or copper alloys, possessing excellent conductivity and mechanical strength. Their structural design enables wires to be conveniently stripped and secured, facilitating electrical connections. Depending on the usage scenario and requirements, terminal connectors can be categorized into various types, including screw-type, spring-type, and plug-in-type connectors.

II. Steps for Using Terminal Connectors

1.Prepare Tools and Materials

Before using terminal connectors, it is necessary to prepare the corresponding tools and materials, including wire strippers, screwdrivers, insulating tape, terminal connectors, and the wires to be connected. Ensure that the quality and specifications of these tools and materials meet the requirements to guarantee the reliability and safety of the connections.

2. Wire Stripping

Use wire strippers to remove the insulation layer from the ends of the wires, exposing a certain length of bare wire. When stripping wires, be careful not to damage the conductor inside the wire to avoid affecting conductivity. The length of wire stripping should be determined based on the specifications of the terminal connectors and the diameter of the wire, ensuring that the bare wire can be fully inserted into the terminal connector.

3. Inserting Wires

Insert the stripped wires into the corresponding holes of the terminal connector. Depending on the type of terminal connector, it may be necessary to use a screwdriver or other tools to secure the wires inside the connector. When inserting wires, ensure that the wires make good contact with the terminal and are free from any looseness.

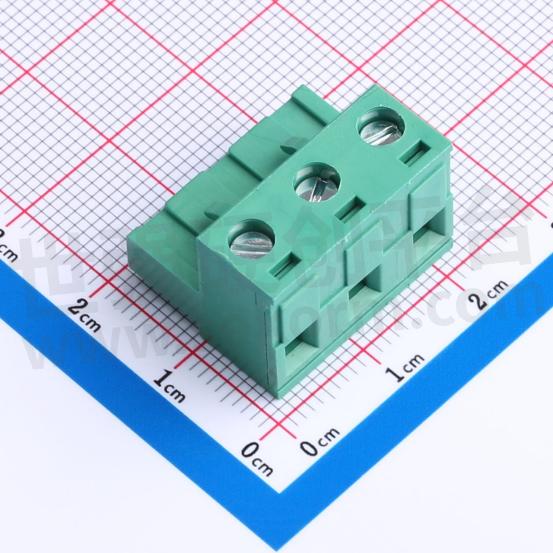

Terminal Connector KH-ZBK300R-3P-7.62G

Check the connection quality

After completing he insertion of the wires, it is important to carefully inspect the connection quality. Ensure that the wires are tightly connected to the terminal blocks, with no loose connections or short circuits. Additionally, pay attention to checking whether the insulation layer is intact to prevent electrical leakage and accidents.

Insulation treatment

To enhance the safety and reliability of the connections, insulation treatment is necessary for the connection points. Insulating tape can be used to wrap around the terminal blocks and exposed parts of the wires to prevent electric shock and short circuits. When applying insulation treatment, ensure that the tape is wrapped tightly and without gaps.

Usage precautions

Ⅰ. Ensure that the specifications of the terminal blocks match the diameter of the wires to avoid using terminals that are too large or too small, which could result in loose connections or damage to the wires.

Ⅱ. When stripping wires, be careful not to damage the conductors inside the wires to avoid affecting their conductivity.

Ⅲ. When connecting wires, ensure that there is good contact between the wire and the terminal without any looseness. Apply moderate force when securing the wires to avoid them being too tight or too loose.

Ⅳ. Regularly inspect the connection status of the terminal blocks. If any looseness or poor connections are found, they should be addressed promptly.

Ⅴ. Store terminal blocks in a dry, ventilated environment to prevent moisture and corrosion, which could degrade their performance.

Through the above introduction, readers should have a deeper understanding of the use of terminal blocks. In practical applications, choose the appropriate type of terminal block according to specific needs and scenarios, and follow the correct operating procedures and precautions to ensure the reliability and safety of electrical connections.

- +1 Like

- Add to Favorites

Recommend

- Kinghelm‘s Pluggable Terminal Block KH-ZBK300R-3P-7.62G, Features High-quality Material Construction, High-performance Design and Plug-in Design

- Kinghelm‘s Pluggable Terminal Block KH-ZBK300R-4P-7.62G with Outstanding Performance and Stability

- Kinghelm‘s Pluggable Terminal Block KH-ZBK300R-6P-7.62G with the Pitch of 7.62mm and a Total of 6 PINs

- Kinghelm‘s Pluggable Terminal Block KH-ZBK300R-5P-7.62G Designed to Meet the Demands of High Current and High-speed Data Transmission

- What is Kinghelm ‘s Influence in the Industry?

- Kinghelm Introduces the KH-GPS080804-WY GPS Passive Ceramic Antenna: Revolutionizing Positioning Technology

- Kinghelm‘s KH-GPS/BD5056SMA-3M Automotive Positioning Antenna: Revolutionizing Navigation and Positioning

- What are Some Popular Pin Header Models Sold by Kinghelm? KH-2.54PH180-1X2P-L11.5, KH-2.54PH180-1X4P-L11.5...

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.