Introduction of China Small Size Power Module Manufacturers

When we choose a power module, we generally look at the quality of the input, output, ripple, breakdown, temperature, certification, and other characteristics of the power supply. Apart from these, we can also judge according to the following points.

1. Circuit principle and soldering process The bare board can use intuitive methods, such as a neat layout of components and potting modules without being exposed and unable to view the internal situation. The quality of the mechanized wave soldering process is better than manual soldering, generous, but Better in terms of safety and performance

2. The core of the power supply of chip components and transformer components is IC, which will directly affect the power and high-temperature resistance of the entire power transformer components. Responsible for accomplishing AC-DC and saturating the fryer during energy overload.

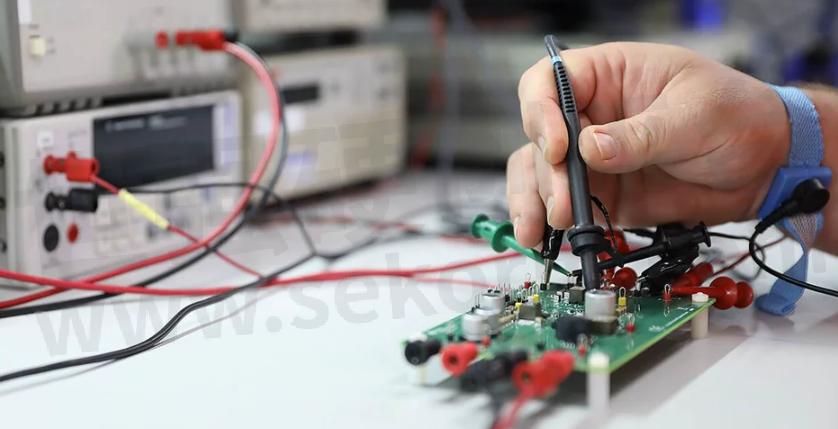

Fig.1

3. Is it an electrolytic capacitor or a ceramic capacitor?

1). The electrolytic capacitor is a temperature-sensitive component after the electrolyte heats up and explodes.

2). Ceramic capacitors are mainly non-polar, and the switching frequency will cause the parasitic resistance of the capacitor to heat up. Good dielectric materials and capacity should not be too large. Most, it is widely used in high-frequency circuits.

4. Batch testing of aging and high-temperature aging No matter how good the quality stability of product materials and production process control is and whether the materials have potential safety hazards, aging needs to be detected. Only through power aging and high-temperature pumping detection.

The benefits of choosing a China Small size power module manufacturers

Power savings of up to 25% can be achieved with these new power switches, and the reduction in power consumption brings many improvements. On the one hand, the heat dissipation design of the heat sink and the overall module can be more compact and have higher cost performance. Providing the same output power but with a smaller product is an important advantage, especially in pump or fan designs. In general, by using smaller electronic drives, controlled motors can be used in applications that were not possible before. Also, reduced use of production materials means lower costs for production, transportation, and recycling, which all boil down to product life cycle costs.

Fig.2

On the other hand, the maximum output power can be increased while maintaining the consistency of the existing design parameters. Products that use the same thermal design but consume less power have higher reliability, because there is less thermal excursion, and the failure rate is greatly reduced. Moreover, the same design can evolve into a variety of different models by simply replacing different output power chips, thereby shortening the time to market.

ZOEYGO has more modules with different powers, if you want to know more, please contact ZOEYGO.

- +1 Like

- Add to Favorites

Recommend

- If You Want to Design A Power Module, What Aspects Need to Be Considered?

- What Is A Power Module?

- How to Choose Quality Clearance, and Reliable Power Module Manufacturers?

- What You Need to Consider When Designing a Power Module

- Power Module Performance Optimization: The Key to Improving Equipment Stability

- Shindengen Launched Compact Power Module MG032 for Large Motor Inverter Circuits

- Power Module: The Heart of Electronic Devices

- Vincotech VINcoMNPC X4 Power Module Provides up to 800A and Suitable for Solar and UPS Applications up to 250kW

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.