About The Importance, Structure and How to Choose The DC-DC Power Module?

With the development of the times, electronic products are more and more developed, DC-DC power modules are widely used in today’s society, and some electrical appliances used in daily life are also applied to them. Do you understand the importance and structure of DC-DC power modules? Know why you should choose a DC-DC power module?

The importance of DC-DC power module:

DC-DC power module is a compact, high quality regulated power supply products, using advanced manufacturing technology. Because the module power supply is simple to use, it has the advantages of convenient expansion and good maintainability when composing the system. Therefore, it is widely used in aerospace, communication power supply, automotive electronics, electronic equipment, power control and other fields. These module power supplies usually require a wide operating power range (36 V to 75 V) and high output power (can provide all-brick module power up to 700W), and the power density is very high, cooling design is a big problem.

For example, the half brick output power of 200W module power supply, its conversion efficiency is 89%, then 24.7W of electrical energy into heat, if there is no cooling measures, half brick module power supply may be damaged due to overheating. Therefore, in the design of high-power module power supply, appropriate heat dissipation design is more and more important.

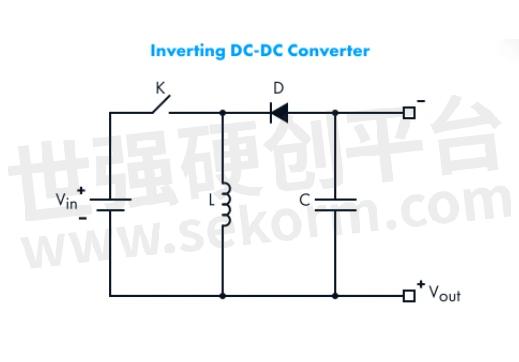

Power structure of DC-DC power module:

The key components of the power structure of DC-DC power module are: pulse width modulator, optocoupler, VDMOS and Schottky diode.

Fig.1

The selection of power modules should be based on the following four points:

1.the use of mature power supply topology

The design of the power module is based on the mature power topology. These topologies have been tested over time and are mature and reliable.

2. high efficiency within the full load range

High efficiency means lower power loss and lower temperature rise, which can effectively improve reliability. In practical applications, the power supply will choose a certain degree of downscaling design, especially in today’s load IC power consumption is getting lower and lower, most of the time the power supply may work under light load conditions. Therefore, high efficiency over the entire load range is a key parameter for power system reliability, but it is often overlooked by power supply manufacturers.

3. limit temperature characteristics

The geographical area where the power module is applied is very wide and may have tropical climate and cold weather similar to Russian winter. Therefore, the minimum operating temperature range of DC-DC module is required to be -40 degrees to 85 degrees. The final temperature test is the most reliable way to verify this. The reliability of the power module, such as high temperature aging, high temperature and low temperature live operation performance test, high temperature and low temperature cycle impact test and long time high temperature and high humidity test, therefore, whether this test equipment has become the basis of judging whether the power manufacturer is a copycat manufacturer.

Fig.2

4. high isolation, low isolation capacitance

Medical products require extremely low leakage currents, while power electronics require as little parasitic capacitance as possible between primary and secondary. Both industries generally require the highest possible isolation voltage withstand and the lowest possible isolation capacitance to reduce the impact of common-mode interference on the system. For medical or power electronics applications, 1-2W DC-DCs are recommended to use a power module with an isolation capacitor less than 10pF, and a wide voltage product with a power module less than 150pF.

- +1 Like

- Add to Favorites

Recommend

- DC-DC Power Modules: Micro Power, Infinite Possibilities

- The New Trend of Energy Saving and High Efficiency, DC-DC Modules Bring Revolutionary Changes to The Power Supply Field

- What are the Rules for DC-DC Power Modules?

- How to Choose China DC-DC Power Module? Why Choose a DC-DC Power

- Bidirectional DC-DC Converter: A Two-Way Power Conversion Solution

- DPX Series DC-DC Converter: Efficient and Reliable Power Conversion Solution

- DPX Series DC-DC Converter: An Efficient Solution for Power Conversion

- Efficiently Convert AC to DC with ZOEYGO Reliable 12V Converter Module

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.