Unrivalled Performance In Critical Environments Solves Interconnect

From satellites and next generation aircrafts to life-saving defibrilators and railway systems connectivity requires superior quality products that offer great performance and optimal reliability under extreme temperature, mechanical Shock and vibration difficult access, water or dirt ingress,and fretting corrosion.

To ensure reliable signal integrity by keeping the product undamaged through a long-life cycle the

manufacturer itself needs to guarantee three key aspects:

1. Selection of rugged and appropriate product materials

2. Proven technical characteristics of the product technology

3. Product compliance with the main international standards for the relevant market

Choosing the right product materials is an important step toward ensuring that the connector will provide a Stable connection despite being subjected to a variety of harsh conditions. Connectors that are lightweight and compact have the added benefits of cost- and space-savings.

A connector with very low contact resistance ensures the minimum temperature rise at high currents. The peak temperature of the insulator material is normally the primary limiting factor in demanding conditions. Materials must be chosen to Support the Widest ambient temperature range (from -55℃ to 125℃) and withstand temperature peaks during assembly, even those generated during vapor phase soldering, while complying with the rail market requirements for fire and Smoke.

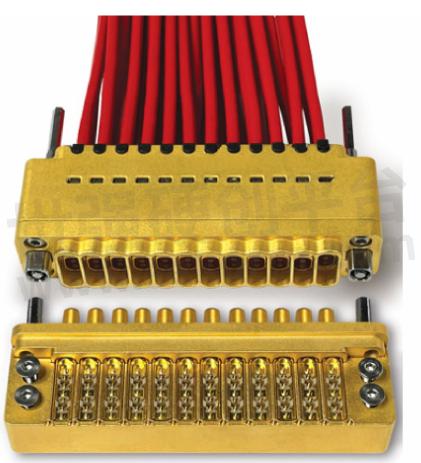

The shape of the contact sleeve in Smiths Interconnects Hypertac socket is formed by hyperbolically arranged contact wires, which align themselves elastically as contact lines around the pinto provide multiple linear contact paths, giving the productimmunity to shock and vibration.

Smiths nterconnect's new Intercompact series is a lightweight compact signal and Ethernet PCB connector specifically designed to provide a stable connection in demanding railand industrial applications. The Intercompact series has been qualified in compliance with the main European railway standards:

CONNECTORS FOR RAIL AND INDUSTRY

Connectors must meet the main European railway standards (EN45545-2, NF F61030, EN50155:2017, STM-S-001ind.D, MIL-C-28748 and MIL-STD-202-301 standards and and more) and comply with EIA and IEC standards for contact resistance and environmental testing

CONNECTORS FOR SPACE

Space applications are a perfect example of the importance of unrvalled performance in critical environments. Interconnect solutions for space must meet the reliability and efficient design needs Of todays satellite and spacecraft challenges. Space satellites are moving away from RF analog-based payloads that provide low-speed telecommunication signaling to a new Digital Transparent Processor (DTP) architecture for high throughput satellites. DTP architectures increase the demand for rugged and higher speed connectivity.

Satellite manufacturers often use large singular printed circuit boards featuring very high value components. The solderless PCB mount design that the NXS Series provides, for example, can be placed and replaced with very low risk to the Customers board reducingthe cost of ownership. The connector is mounted after reflow and has no impact on nearby components. Each product is engineered using 3D electromagnetic simulation (EM) software to provide excellent performance in a total thin film process.

SmithsInterconnects NXS Series is an advanced high- speed high-density interconnect equipped with the proven Hypertac hyperboloid contact technology to withstand data rate application requirements up to 10 Gb/s (per channel), including extreme levels of vibration, shock, and climatic testing above 2100 G. The NXS Series is designed in a robust construction with 4 or 12 high-speed quadrax modules containing 2 dual Twinax at 100 0 each pair. This ultra-high contact density and compact form factor allows the customer to make a 90 transition within a very small footprint. It is blind-mateable, hot-pluggable, with ultra-low mating forces, and low outgassing materials.

SmithsInterconnects SpaceNXT initiative is a full range of higher-reliability products for next-generation

Meeting those industry needs requires high-speed, high-density interconnects that can provide next-generation data on demand and can withstand high data rate application requirements, including extreme levels of vibration, shock, and climatic testing above 2100 G. To be qualified, they must meet rigorous testing and performance criteria ESCC 3401, ESCC 3402, ECSS-Q-ST-70C, ECSS-Q- ST-70-02, ECSS-Q-ST-70-08C, ECSS-Q-ST-70-38C, and ECSS-Q-70-71.

The selection of rugged, qualified, and dependable materials combined with proven, reliable, and flexible contact technology and full compliance with industry standards i critical to creating successful connectivity solutions for the challenges presented by space.

- +1 Like

- Add to Favorites

Recommend

- Smiths Interconnect Intercompact Series Connector Optimized and Qualified for Next Generation Electronic Control Units

- Smiths Interconnect Acquires Reflex Photonics to Expand in High Speed Data Transmission Market

- How Smiths Interconnect Keeps The Medical World Connected

- Smiths Interconnect Expands into Burn-In Test Market with Acquisition of Plastronics

- Smiths Interconnect New Hypertac Green Connect Contact Technology is Designed to Reduce Power Loss

- Smiths Interconnect Expanded RF Filter Capability for European and Asian Markets

- Smiths Interconnect’s cPCI launched on NASA Mars Perseverance Rover – Interconnect Product of the Year

- An Introduction to Smiths Interconnect in Dundee

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.