What Is UPS in PLC?

Programmable Logic Controllers (PLCs) play a crucial role in industrial automation, managing and controlling manufacturing processes with precision. To ensure the uninterrupted operation of PLCs, especially in critical applications, it is essential to consider a reliable power backup solution. Uninterruptible Power Supplies (UPS) come into play as a safeguard against power disruptions that could compromise the functionality and reliability of PLCs.

What Is a PLC?

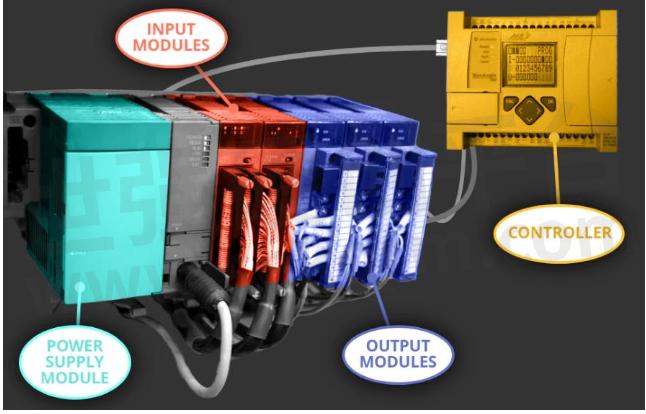

A Programmable Logic Controller (PLC) is an industrial computer specifically designed for controlling and automating manufacturing processes. PLCs are robust, versatile devices that execute logic operations, process inputs, and generate outputs to control various machinery, assembly lines, and robotic systems. PLCs are vital in achieving efficiency, reliability, and precision in various industrial applications.

Fig.1

Main Components of a PLC

The operating principle of a PLC involves the sequential execution of a stored program. The CPU reads input signals, processes the logic based on the programmed instructions, and produces output signals to control external devices. This cyclical process allows PLCs to respond rapidly to changing conditions, making them well-suited for real-time industrial applications. A Programmable Logic Controller is composed of several key components, each playing a crucial role in the overall functionality of the system. The main components of a PLC include:

◆Processor (CPU) and Memory

The Processor consists of the CPU (central processing unit) and memory. The processor section makes decisions needed to observe and operate the field devices connected to the Input/Output modules. The decisions are based upon a user-created program saved in the memory. The memory also stores data representing the condition of all input field devices and contains the data telling the output field devices what to do.

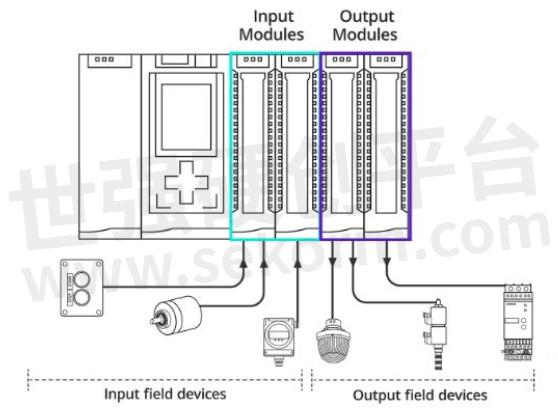

Fig.2

◆Input/Output Modules

Input modules are responsible for interfacing with the external environment by receiving signals from sensors and other input devices. These signals, representing the state of physical processes, are then processed by the CPU. Output modules are responsible for sending control signals to actuators, relays, or other output devices. These signals influence the physical processes being controlled by the PLC.

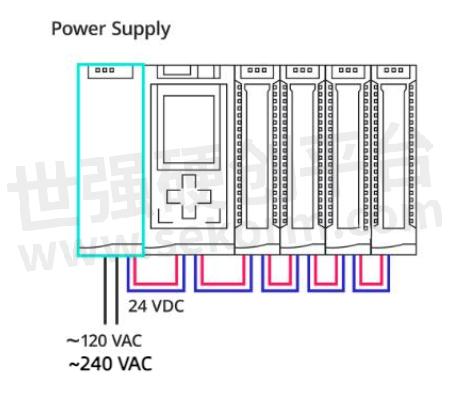

Fig.3

◆Power Supply

The Power Supply is connected to AC mains for the supply voltage. The output of the Power supply is a DC voltage used to power all of the other modules associated with the PLC. Usually, the input power of the PLC system is 120V/240V AC, and the output power is 24V DC. This DC voltage is then sent into the rack to power the rest of the PLC components. The Power supply DOES NOT provide power for field devices.

Fig.4

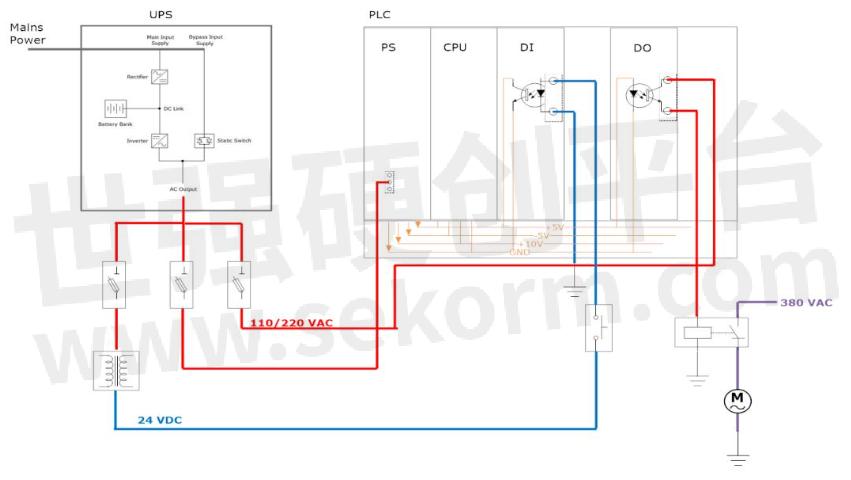

What Is UPS in PLC?

An UPS is a critical element in industrial settings where power disruptions pose a significant risk. A UPS ensures continuous operation of PLCs by providing a seamless transition to backup power during power outages or disturbances. The UPS can be used for two purposes. Feeding the power supply of the PLC or feeding the power supply for the control circuits that are wired to the I/O cards of the PLC. Which solution(s) are adopted in an application depends on the requirements of the application and also on the specifications and performance of the UPS. Following figure shows a typical wiring circuit when using a UPS system in the power circuit of a PLC.

Fig.5

Conclusion

The article focuses on the vital role of Uninterruptible Power Supplies in ensuring continuous operation for Programmable Logic Controllers in industrial automation. It briefly outlines the efficiency and versatility of PLCs, highlighting their key components such as the CPU, memory, input/output modules, and power supply. The article emphasizes the significance of UPS as a critical element in industrial settings, providing a seamless transition to backup power during disruptions to safeguard PLC functionality. As a global leader in lithium battery cell manufacturing, Grepow offers professional customization solutions for 12V and 24V UPS battery and Battery Management Systems (BMS), catering to your specific application requirements.

- +1 Like

- Add to Favorites

Recommend

- What Is a UPS Battery?

- UPS Battery Market Forecast Research Report

- What Is UPS Battery Backup?

- 12V UPS Battery FAQs

- Shorter-Than-Expected UPS Battery Life Increases Maintenance Burden

- Frequently Asked Questions for UPS Battery Replacement

- 5 Advantages of Lithium-Ion Battery Operated UPS SANUPS E11B-Li

- DC UPS vs AC UPS: What’s the Difference?

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.