CAPTRON Hygienic Sensors and Signaling Lights for Cleanrooms and Cleanroom Systems Achieve Optimal Cleaning and Meet Stringent Safety and Germ Reduction Requirements

Ortner Reinraumtechnik relies on innovative sensors

Hailing from Villach, Carinthia, Ortner Reinraumtechnik GmbH has offered systems and technologies for a broad spectrum of cleanroom applications in high global demand for over 30 years. Its customers come from demanding industries such as pharmaceuticals and biotechnology, healthcare, various laboratory sectors, and the semiconductor and food industries. Combined with solutions from Ortner, CAPTRON products have proven effective in a wide range of practical applications. Ortner relies on CAPTRON solutions in many of its products.

“The company offers a wide variety of products in the area of capacitive sensor technology, delivering reliable solutions that can be optimally integrated into our systems.” (Wolfram Kofler, Product Manager at Ortner Reinraumtechnik)

CAPACITIVE TECHNOLOGY FOR OPTIMAL CONTROL IN PERSONNEL AIR SHOWERS

One example is the JET personnel airlock developed by Ortner. Personnel air showers are critical in the pharmaceutical and life sciences industries for removing particles from cleanroom clothing. With its pulse and vibration effects, the JET nozzle technology developed by Ortner removes and shears particles from the clothing. An optimized laminar displacement flow ensures efficient particle removal, preventing the possible re-contamination of personnel. The defined position of the person in the air shower is monitored by sensors, guaranteeing a verified, validatable cleaning process.

capacitive sensorswitches are integrated into the left and right walls within the personnel lock to monitor the person’s stance. To start the process, users have to touch both SENSORswitches simultaneously with their palms to ensure they are in the correct position in the airlock. Next, the JET air cleaning process is automatically started for the configured time. If the user leaves the defined position during this period, they are requested to return to the position on the integrated display, and the process is ended.

CUSTOMER BENEFITS

This capacitive technology has proven effective in the sensors. A capacitive field is generated on the surface of the SENSORswitch and is measured continuously. When the button is touched, energy flows off. The difference between the generated energy field size and the measurement determines the switching behavior. Even the basic systems feature capacitive sensors from CAPTRON, which ensure the correct position of the individuals in the lock and thus help to achieve optimal cleaning.

Reliable function, ensured when using even thick rubber gloves thanks to the capacitive principle, was just one reason for choosing the CHT1, one of the top models from CAPTRON’s range of capacitive buttons. These solutions also guarantee a long service life with a high number of switching cycles.

No fastening screws required

Hygienic installation possible

Simple clip assembly and M8 connector

The easy-to-clean edgeless button surface

Fully electronic button without moving parts

Hygienic cleaning

Extremely robust and resistant design (IP protection)

HYGIENIC STAINLESS STEEL BUTTONS FOR MAXIMUM DEMANDS IN TRANSFER HATCHES

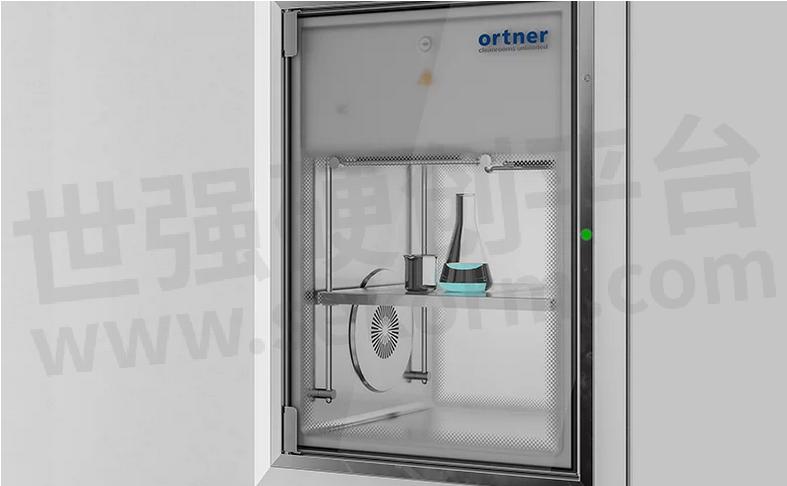

These same benefits made the flush-fitting CHT1 the first choice for Ortner’s Comfort S6 transfer hatch introduced in early 2020. This practical, effective solution ensures quick and reliable transfer between rooms of different cleanroom classes. Transfer hatches help control the loading and unloading of different materials and products in hygiene-critical environments, which is required in production in the chemical, pharmaceutical, and life sciences industries in research labs and cleanrooms, for example.

The solution is conceptualized as a standalone device with end-to-end air management in a hygienic design. Constant chamber pressure regulation and HEPA filters on the inlet and outlet sides ensure a turbulent airflow and permanently cleaned air.

HYGIENIC signaling lights FOR CLEANROOM SYSTEMS

A third Ortner product featuring the hygienic version of CAPTRON’s Multi-LED CML1 is the DecAx cleanroom system. The system is specifically designed for processing and primary packaging in food production. It filters the air and sterilizes the interior surfaces of devices based on a low turbulence displacement flow. The system’s two-stage design is referred to as “hurdle technology.” The DecAx product line easily meets the stringent requirements in terms of product safety and germ reduction when it comes to processing meat, delicatessen, and sausage products.

IDEALLY EQUIPPED FOR THE FUTURE

Ortner will continue to rely on CAPTRON components in future developments. These components can easily be integrated into new products thanks to the wide range of different attachment options, including hygienic snap-in technology. Other important factors include the materials, such as V4A stainless steel, and the different connection options, including M8 plugs with a high IP protection category. The use of IO-Link in the newer CAPTRON series makes them the perfect fit for Ortner’s general strategy for measurement and control technology.

Specifically, the company already plans to include the newly developed series10 capacitive sensors in addition to the CHT1. About the operation and electrical parameters, it offers an even more flexible configuration. This includes switch sensitivity and minimum actuation time, the actuation dynamics, interface behavior (PNP, NPN, relay, IO-link), and general functions (static, dynamic, toggle). The color of the light, color changes upon actuation, and parameters such as static or flashing lights can also be custom-configured. “Our devices undergo ongoing development and are continuously adapted to the changing requirements of our customers,” Wolfram Kofler says.

“With CAPTRON, we found a partner that provides us with optimal components in line with our high pace of innovation.”Wolfram Kofler, Product Manager at Ortner Reinraumtechnik

- +1 Like

- Add to Favorites

Recommend

- CAPTRON Solutions causes a stir at LogiMAT 2024

- ISAC Mobile Order Picking System from CAPTRON Solutions Wins the Six Challenge 2024

- Certified Hygienic Design with CAPTRON CANEO Series10 Capacitive Switches Made Food and Pharmaceutical Production Easy

- CAPTRON oneGRID Pick-by-light System Makes Picking Process Efficient

- Machine Processes Quality Assurance with Captron Fork Light Sensors and Laser Measurement Technology

- Capacitive Sensor Switches Will Meet Challenges from Future Tightening Hygienic Standards in Food Industry

- InvenSense Announces SensorStudio 2.3 Supporting Dataflow-Based Custom Sensors

- Diotec‘s RGL34J with an IFAV of 0.5A a VF<1.3V and trr<250ns can be used in the capacitive power supply unit such as light sensors

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.