Passive Components Usher In New Growth Opportunities In The Era Of Electrification.-Resistors

Resistors are used to control current and voltage, and their main functions are current limiting and voltage reduction. The main function of a resistor is to hinder the flow of current. Any current passing through the resistor will be subject to certain obstacles and restrictions, and the current will inevitably produce a voltage drop on the resistor. As a current limiting element, the larger the resistance value, the smaller the current. As a voltage-reducing component, the larger the resistance value, the greater the voltage drop. Based on the voltage-reducing effect of the resistor, the resistor can also be used as a voltage divider, and the resistors are connected in series to achieve the voltage-dividing function.

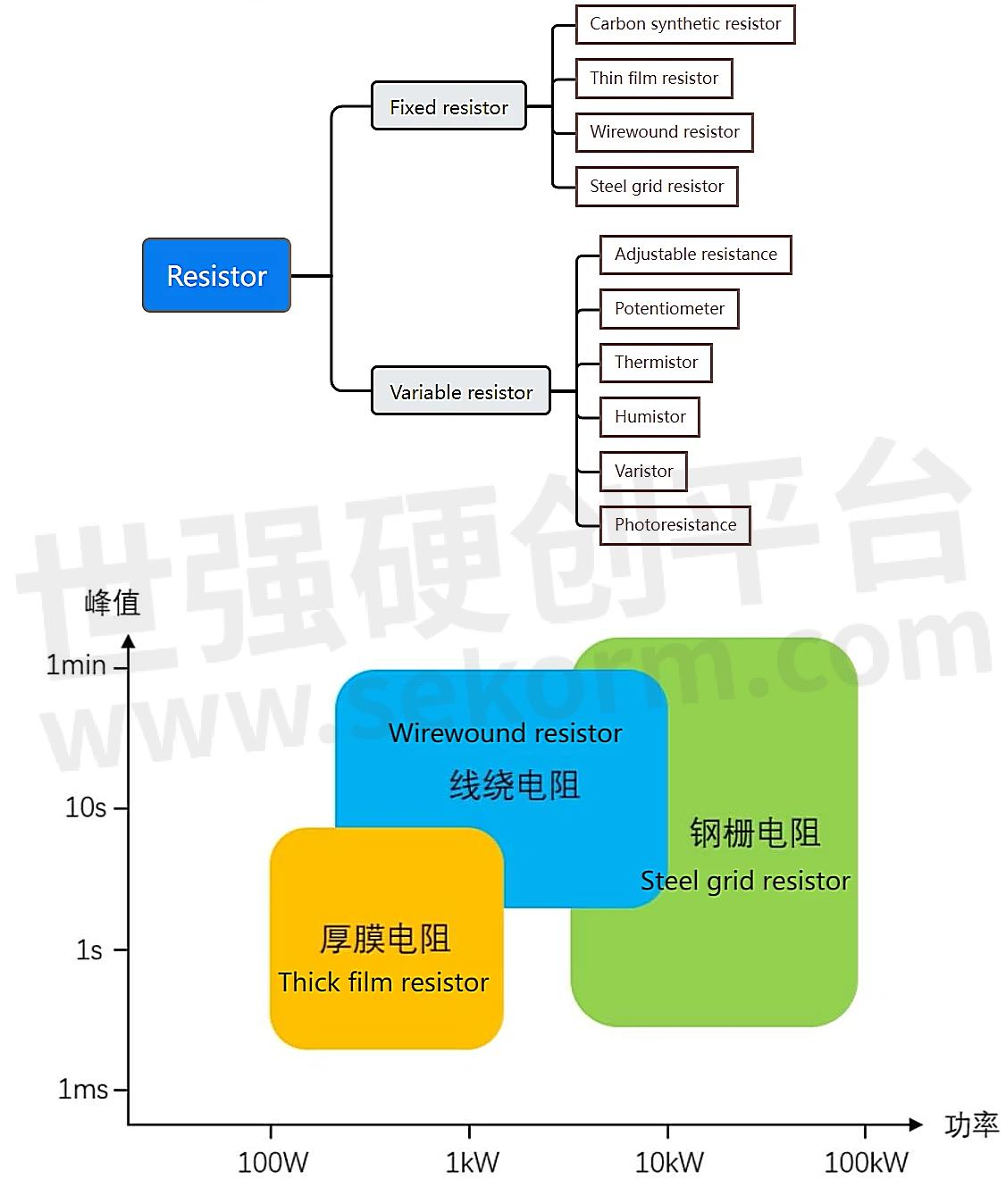

There are many types of resistors, which can be divided into multiple types based on material technology, structural form, and whether the resistance value changes. According to the structural form, resistors are divided into lead resistors and chip resistors. Lead resistors are divided into wire-wound resistors, carbon synthetic resistors, carbon film resistors, metal film resistors, and metal oxide film resistors according to the raw material process. Divided into thick film resistors and thin film resistors. According to whether the resistance value can be changed, it is divided into fixed resistors and variable resistors. Fixed resistors include carbon synthetic resistors, thin film resistors, wire-wound resistors, and Steel grid resistors. Variable resistors include manually adjustable resistors, potentiometers, Thermistors, hygroscopic resistors, varistors, photoresistors, etc. whose resistance value changes according to external temperature, humidity, voltage, and illumination.

Common resistor application scenarios are generally divided into general-purpose and precision types. Resistors are widely used in computers, communications, home appliances, consumer electronics, automotive electronics, and other fields. They are indispensable and widely used electronic components in various electronic manufacturing industries. In the general field, thick film resistors are most used due to their cheap price, wide resistance range, good stability, and reliability; in the precision field, metal foil resistors in thin film resistors have become the future development direction due to their best temperature stability.

Fig.1

In the field of new energy, thick film resistors and Wirewound resistors are most commonly used. wirewound resistors are the most common power resistors. Wirewound resistors are usually made by winding resistance wire on a ceramic insulating substrate. They are characterized by a simple process, economical price, and a single resistor power of up to 2500W. The disadvantage is that they are bulky. , has inductance and poor reliability. It is the only resistor with a wide power handling range in terms of application scenarios. Thick film resistors are usually based on thick film resistor paste printed on aluminum oxide or aluminum nitride substrates. They are characterized by high power density, non-inductance and capacitance, and a wider range of resistance values. The disadvantages are limited overload capacity and high heat dissipation requirements. , it is the first choice for higher power density resistors in terms of application scenarios. Steel grid resistors are mainly used for energy dissipation.

Table.1

- +1 Like

- Add to Favorites

Recommend

- ZETTLER Presents New AZEV400 Relay with Outstanding Short-Circuit Resistance for EV-Charging Applications at the Electronica 2024

- Exxelia Ohmcraft‘s Cutting-Edge Resistors Redefining Reliability in the Aerospace Industry

- Resistors for Battery Management Systems

- Viking’s New ARN Series Aluminum Nitride Based Thin Film Chip Resistors Offer 2 Times Power Rating over Traditional Thin-film Chip Resistors

- Exxelia’s Proprietary Micropen® Precision Printing Technology Produces Superior High Voltage Resistors for the World’s Most Advanced Medical Applications

- Exxelia Ohmcraft Custom Resistors Enable Rapid COVID-19 Testing

- Powering the Future: The Crucial Role of Resistors in Electric Vehicle Charging

- Exxelia will be Displaying Innovations in Magnetics, Capacitors and Resistors at Electronica 2022

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.