What You Should Know about Wound Magnetics Technologies

EXXELIA designs and manufactures magnetic components including wound magnetics, inductors, transformers, motors, sensors, and actuators for high voltage, high temperature, and power applications.

Products are optimized to meet the most demanding application requirements thanks to strong design expertise, EXXELIA masters High-Grade technologies: Chameleon Concept Magnetics (CCM), standard linear and toroidal, toroidal transfer molded technology (TT), SESI planar / Low-profile and aluminum foil winding.

DESIGN CAPABILITIES

Exxelia designs magnetics for most applications:

Switch-mode power supply including new

and unusual architectures

360-800Hz Power supply

(single and multipulse)

50Hz power supply

Current and Voltage measurement

Lighting - Ignition

Pulse transformer (gate drive, data)

Micro inductor

Audio-frequency

Electromagnets etc.

Exxelia designs magnetics up to:

200kV dielectric strength

20kV operating voltage …

240°C operating temperature

According to the main aerospace

standards

ESA ESCC 3201

MIL-STD-981

MIL-PRF-27

D0-160 etc

SWITCHED MODE POWE SUPPLY

Cross-regulation in multi-output Flyback converters

Exxelia has been working on this subject in order to understand the phenomenon, identify the cause(s), and find solutions to avoid the use of linear regulators consuming energy.

The identification of a relevant magnetostatic model of the transformer and its electronic environment is necessary for the analysis of the phenomenon in circuit simulation software like PSIM or PSPICE. This allows us to evaluate the influence of the model parameters and the other components of the converter on the variability of output voltages.

The key point is then to link the product manufacturing technology to the parameters of the model, in order to reduce cross-regulation thanks to the optimization of windings arrangement.

The work on this topic allows precise control of the output voltages on the most sensitive windings.

Dual Active Bridge, small size & high efficiency

The dual active bridge is a topology more and more used to supply batteries because it allows bidirectional energy transfer with the network.

Exxelia is developing high reproducibility technology to integrate inductors in the transformer:

Example :

3 Transformers in each power supply

Each transformer incorporates virtual inductance Lk

15 kW combined output @ 100kHz switching

Taps provide flexibility for 350V / 700V input & 28V or 56V output (up to 430A)

Exxelia value proposition: Small size, high efficiency, competitive cost despite

multiple high current outputs and integrated inductors.

360-800HZ MULTI PULSE

Exxelia developed a specific knowledge to optimize the design of single and multi-pulse magnetics for 360 – 800Hz power networks.

ACCURATE MEASUREMENT TRANSFORMERS (0.1%) FOR CRITICAL APPLICATIONS

Real-time, detailed knowledge of the voltages and currents is becoming increasingly important to ensure the proper operation of electrical networks. This is as true for the aeronautics market as it is for the industrial market.

Measurement transformers, whether current or voltage, are sensors. They must faithfully transmit a signal level in a highly variable environment (excitation, frequency, temperature) which influences their characteristics.

Exxelia developed a design method that takes into account all environmental conditions. The behavior of the sensor is modeled by a transfer function that depends on transformer characteristics and on the load resistance.

Depending on the application and the targeted accuracy, Exxelia defines the best operating point of the sensor by calculating the worst-case errors with respect to the variability of the model parameters.

Exxelia designs sensors with an accuracy of up to 0.1%.

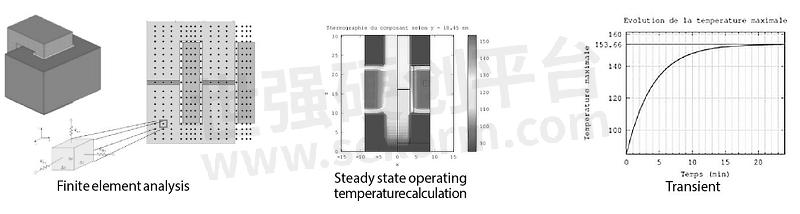

THERMAL MANAGEMENT, A PATH TO MINIATURIZATION

For Exxelia, better thermal management translates into miniaturization of the component.

Indeed, thanks to an accurate calculation of the maximum operating temperature, Exxelia can design the smallest component able to transfer a given power.

The calculation of this temperature requires knowledge of the heating sources (core and copper losses) and the component thermal behavior.

Exxelia uses a calculation method to make the best use of core loss data and improve them by developing partnerships with core manufacturers.

The copper losses due to Eddy current are taken into account by Exxelia through the identification of the overriding causes and the use of the most relevant analytical approaches to evaluate them.

The calculation of the operating temperature from the losses requires determining the thermal resistance, which varies according to the ambient temperature, the power dissipated, and the exchange conditions with the environment.

Exxelia performs measurement campaigns to determine the thermal resistances and their variation for its qualified technologies and for most of the standard ferrite shapes. In particular, the influence of natural convection is taken into account to address products for Space.

When more detailed analysis is required, Exxelia has developed a unique thermal simulation software, based on finite element calculation and dedicated to magnetic components to make its use easier and faster.

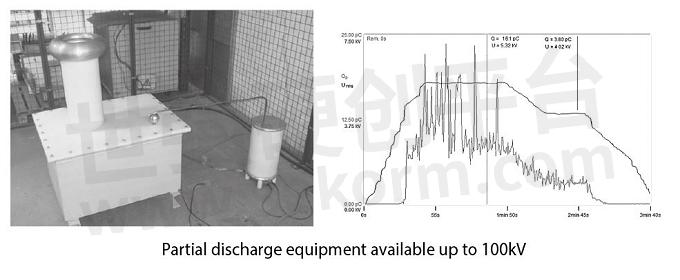

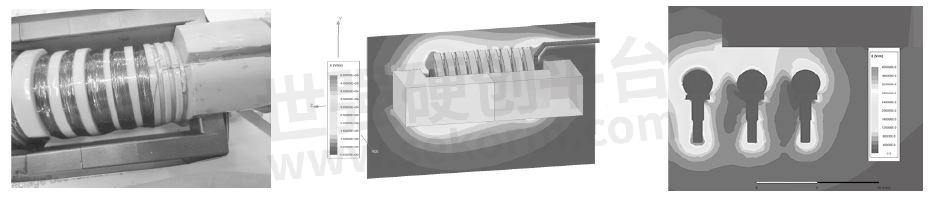

HIGH VOLTAGE AND ELECTRIC FIELD CALCULATION

Exxelia developed specific design skills to anticipate voltage increases requested for aircraft and space-embedded applications. High voltage topic is mastered with both dedicated test equipment (up to 100kV) and electric field calculation know-how.

Electric Field Mitigation:

In high voltage applications, local high electric field E [kV/mm] can lead to premature aging of insulating parts ou insulators? (Partial discharge) and finally to an electric failure.

Simulation in the design phase, using finite element calculations with 2D or 3D electrostatic software allows Exxelia to reduce high field areas and increase lifetime.

Example: Electric Field, Iso-Voltage values

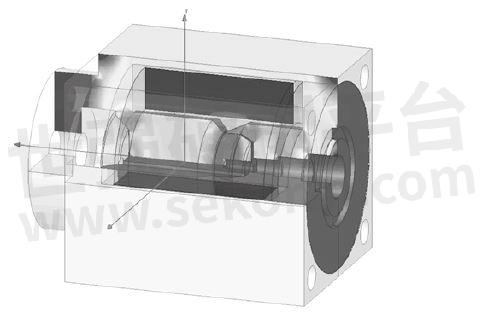

ELECTROMECHANICAL DEVICES

Exxelia engineers use advanced finite-elements simulation software to model and analyze electromagnetic behavior.

EXXELIA can provide a high added-value support for electromechanical device optimization through electromagnetic and thermal calculations (weight reduction, torque increase, losses reduction, etc…):

• 2D and 3D calculations:

Magnetostatic: B[T], J[A/mm²], L matrix (function of current)

Electrostatic: E[kV/mm], C matrix

Eddy current (AC) in magneto-harmonic

2D transient coupled multiphysics (electric + magnetic + circuit)

Specific analysis:

Optimization under constraints

Parametric analysis

Sensitivity analysis

CAD geometry and circuit import/export (step, Catia, Spice, … )

Some calculations: Torque [N.m], Force [N], Resistance [Ω], Losses[W], L matrix [H], C matrix [F]

Some applications: linear or angular electric motor, electromagnet, linear or angular actuator, proportional valves, position sensor, etc… Proportional Hydraulic Valve

Topology analysis:

Based on extensive experience, Exxelia can offer the best topology dedicated to an application or look for the best performance within a given space:

Torque, field, and geometrical optimization

HOW EXXELIA SUPPORTS THE KEY PROCESSES?

CLEANING PROCEDURE

The cleaning of the PCB boards is evolving from a solvent (such as isopropyl alcohol,...) to a highly alkaline water-based cleaning medium.

EXXELIA has performed an extensive study to offer robust technologies to withstand these current cleaning processes.

MECHANICAL TESTINGS.

EXXELIA has defined gluing, marking, and varnishing processes that allow the products to go through more than 5 cleaning cycles and operate up to 180℃.

Processes compliant with ESA and NASA outgassing standards have also been defined for products specified up to 140℃.

WIRE INTEGRITY

EXXELIA has qualified specific processes to ensure wire integrity for better insulation. The wire undergoes mechanical, chemical, and thermal stresses during the winding and cabling process steps. EXXELIA has set up a dedicated process to reduce the impact of these manufacturing steps and improve the overall reliability of the wires and products.

FINISHING

EXXELIA offers several types of components: Surface-mounted Devices, Through-hole or lead terminations products, system integrated components.

PACKAGING

Products are available on trays and, upon request, on reels for easy pick and place, ESD-compliant.

EXXELIA products offer components compliant with IPC/JEDEC standard J-STD- 020 with TP = 260℃ and tP = 30 seconds.

Exxelia is a manufacturer of complex passive components and precision subsystems focusing on highly demanding end markets, applications, and functions. Exxelia's product portfolio includes a wide range of capacitors, inductors, transformers, resistors, filters, position sensors, slip rings, and high-precision mechanical parts serving numerous leading industrial areas such as aerospace, defense, medical, rail, energy, and telecommunications.

Thanks to extensive design capabilities and a robust development process, Exxelia is recognized for its ability to quickly evaluate application-specific engineering challenges and provide cost-effective and efficient solutions. For requirements that cannot be met by EXXELIA catalog products, EXXELIA offers custom configurations: upgraded performance, custom geometries, and robust packaging.

EXXELIA Magnetics business unit has more than 40 years of experience in the design, industrialization, and manufacturing of magnetics for Space, Civil Aviation, Defense, Oil and gas, Medical, Railway, and Industrial niche markets.

EXXELIA actively works in partnership with the customer from the prototype phase to the production series.

EXXELIA has several production sites including low-cost factories. All Magnetics sites are EN/AS9100 qualified. EXXELIA can therefore offer the most competitive solution to the customer.

EXXELIA offers PCB-mounted components, ruggedized medium power magnetics subassemblies as well as stators & rotors, and actuators. EXXELIA has a large technology portfolio including High-Grade platforms for demanding markets and a strong manufacturing heritage.

The customer benefits from EXXELIA's design expertise and know-how for their design to specifications and built-to-print requests. Both catalog and custom products are available. The qualification of technological innovation and the definition of the related design rules allow EXXELIA to offer cost-effective optimized solutions.

CUSTOMER BENEFITS

Time to market:

Available qualified technologies for harsh environment

Strong heritage in Space

Optimized solutions:

Co-design through partnership with technical teams

High expertise in complex designs

Knowledge of the applications

Industrialization know-how

Cost-effective solutions:

Reduced Non-recurrent Cost, Low-Cost Country Sites

Obsolescence management.

- +1 Like

- Add to Favorites

Recommend

- Magnetics at Extreme Conditions: Exxelia To Showcase Innovations at APEC 2024

- New Magnetics Line Enhances Taoglas’ Connectivity Portfolio

- Exxelia will be Displaying Innovations in Magnetics, Capacitors and Resistors at Electronica 2022

- Zettler Magnetics Expands High Performance (HP) Series and Lower Cost (ZP) Series of Power Modules

- Understanding RJ45 Jack without Integrated Magnetics: A Comprehensive Guide

- LINK-PP Introduces LPJG0933H11NL: High-Performance RJ45 Integrated Magnetics for BeaglePlay Gigabit Ethernet Connector

- Exxelia‘s CMSE 2024 Presentation: Innovations to Counter Transient Threats in Magnetics

- Zettler Magnetics EV-RCD Module Supports Residual Current Protection Solution for EV Charger

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.