Delta Superflo Bearing Fans Improved Sleeve Bearing System - Best Choice For Performance Desktop, Workstation, and Other Consumer Electronics

Extensively improved sleeve bearing system. Best value fan choice for performance desktops, workstations, and other consumer electronics.

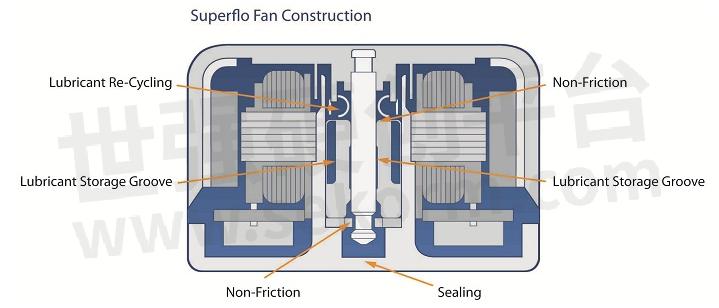

Representing a decisive step forward in sleeve bearing technology, Delta Superflo Bearing fans are this culmination of innumerable hours of research and development. The results of which are newly augmented mechanical structures that ensure permanent lubrication of the spinning mechanism. This is achieved through multiple improvements to the inner lubrication system, pump dynamics, sealing, and flow. Featuring an anti-gravity oil pump, Delta Superflo Bearing Fans recirculate internal oil reserves endlessly within a chamber sealed by dual labyrinth seals. This flow, combined with heat and pressure created through centrifugal forces during operation, minimizes friction and noise while extending the working life of the fan.

Cost-Conscious Long-Life Superflo Bearing Fans: Recognizing that sleeve bearings represent a common, cost-effective approach to cooling needs, Delta SuperFlo Bearing Fans offer a cost-conscious upgrade to assist in minimizing costly maintenance cycles. Inherent in these upgrades are commensurate improvements to radial vibration, excellent anti-shock, a wide range of applied operating temperatures, and overall noise reduction. These all contribute to reducing equipment failures due to overheating because of fan failure and replacement of fans.

Common Applications: As an often-overshadowed critical component, Delta Superflo bearing fans help maintain proper operating temperatures of core PC components such as the CPU and Power Supply. These are integrated into the CPU cooler and internally in the Power Supply. A wide array of consumer products in various other categories benefit from Superflo bearing fans to maintain their necessary thermal characteristics during operation.

Features:

Potentially integrated into a wide variety of applications, SuperFlo Bearing Fans key operational enhancements are as follows:

Redesigned sealing and oil flow paths

Greatly reduced friction and noise

Better acoustic performance over 2-ball bearing fans at low-speed operation

Superb anti-shock

Operating life guarantee (L10) 50,000 hours at 40℃ minimum

Wide applicable temperature range

The Superflo Bearing System represents a mechanical advancement in sleeve bearing systems, featuring a permanently lubricated spinning mechanism for Delta fans. The Superflo system includes an anti-gravity oil pump that re-circulates and recycles the oil in a sealed chamber with dual labyrinth seals. Superflo fans can be used in many of the Delta fan series*.

*In the Delta fan naming system, the second digit “U” signifies a Superflo fan.

The Superflo AUB Series fan L10 life is guaranteed for 50,000hrs@40

compared to regular sleeve bearing L10 life of 30,000hrs@40

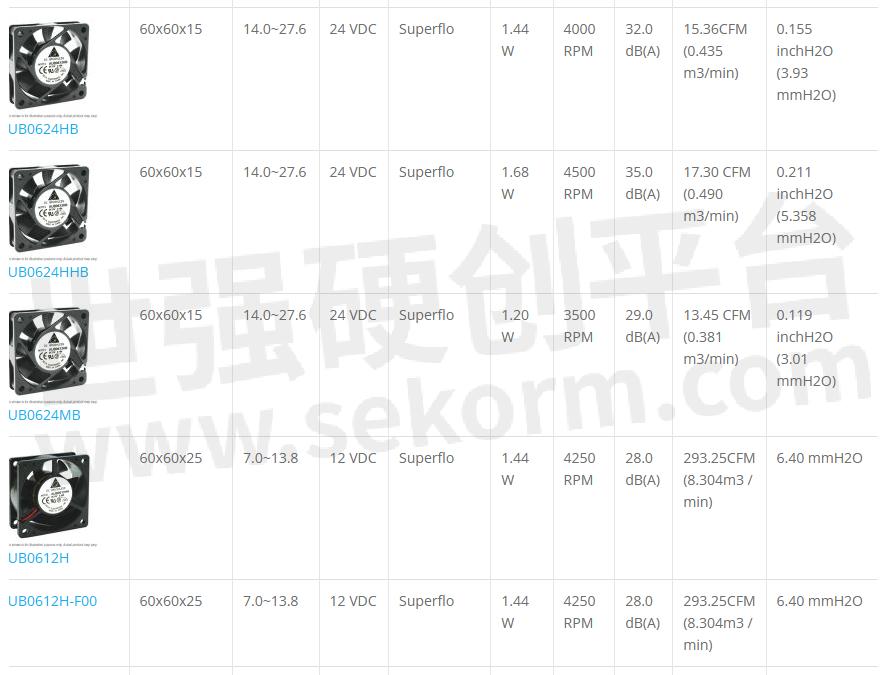

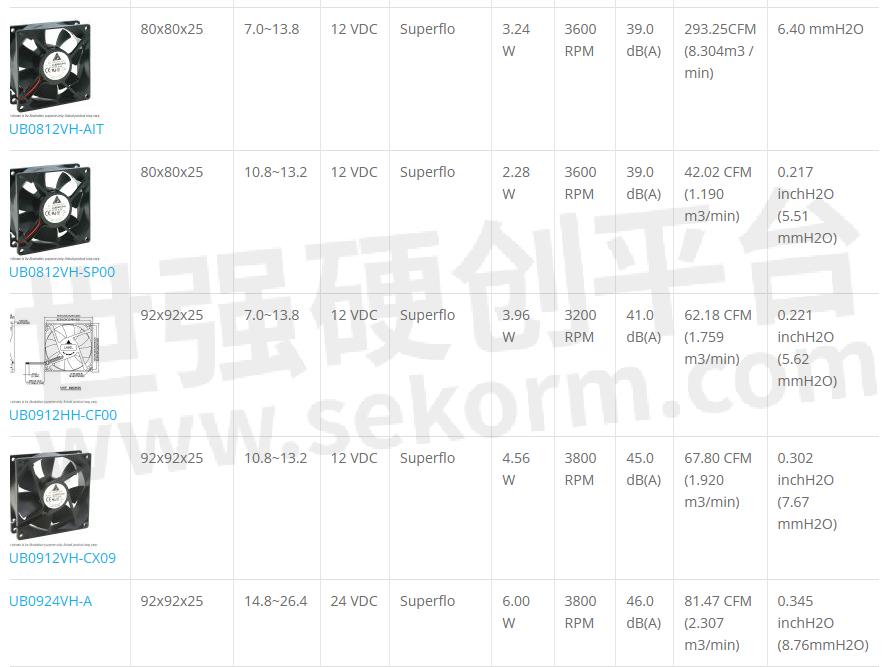

AVAILABLE MODELS:

- +1 Like

- Add to Favorites

Recommend

- Delta Superflo Bearing Fans with Permanently Lubricated Spinning Mechanism Offer High Reliability and Reduce Costly Maintenance Cycles for Consumer Product Cooling Applications

- Deltaww Telecom Product Cooling Systems That Improve The Quality Of Life

- The Industry Leader Deltaww In Cooling Solutions for It Applications and Systems

- Deltaww 3-Phase Brushless DC Motor Fan Featuring a Optimized Blade Design for High-efficiency

- Deltaww ASB 30x30x10mm D sleeve Fan Series – Purposefully Built to Fit Modern Space Constrictions in Electronic Designs

- Deltaww’s Ingress Protection 68 IP68 Fan Series for Outdoor Applications and Harsh Industrial Areas

- Deltaww Designed EC Commercial Refrigerator Fans Featuring Low-noise Blade Design and Low Power Consumption

- Delta Launched in 2021: PFB-E & GFB-E Fans Series with Highest Speed Fans with Greater than 30,000 RPM

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.