Transfer Molded Power Inductor—WT Series greatly Reduce the Possibility of Damaging The Coil Insulation Layer

With the development of the social economy and the improvement of consumption levels, customers tend to pay more attention to the quality of products. The transfer molded inductor of the WT series adopts innovative low-pressure molding technology, compared with conventional dry press molding, the pressure of transfer molding technology is extremely low, which is only about 5% of the dry compression molding pressure (400MPa-1000MPa). It greatly reduces the possibility of damaging the coil insulation layer and crushing the solder joint during the molding process and fundamentally eliminates the "open and short circuit" problems that have long bothered the industry. At present, the size of the product covers the range of 2.0*1.6/2.5*2.0/3.2*2.5/3.2*3.0/4.0*4.0/6.0*6.0/7.0*7.0mm and other sizes, which can be applied to servers, power modules, DDR5, medical equipment and other applications with high-reliability requirements.

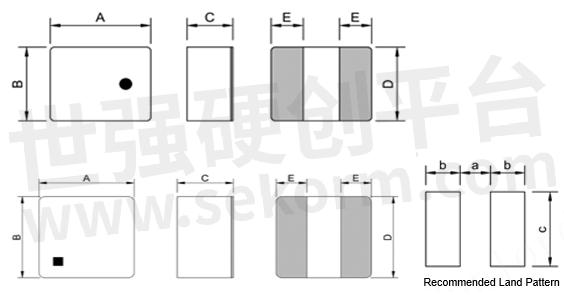

Product images

Fig.1

Applications

●High-end phones, tablets, 5G modules

●Server, base station, etc.

●Various DC-DC conversion power modules

Background

Due to the use of high-pressure molding technology and lead frame structure, the traditional molded inductor may be damaged by the high pressure, resulting in the risk of short circuit, and the lead frame welding is prone to open circuit failure, which is extremely unacceptable for industrial, medical and other equipment with high-reliability requirements. Based on this background, SUNLORD Electronics innovatively adopts low-pressure molding technology and bottom-end electrode structure, which solves the risk of open and short circuits of molded inductors from the source, and due to the use of low-loss magnetic materials, the product has the characteristics of high reliability and excellent electrical properties.

Features

●High reliability, wide operating temperature from -55℃ to +155℃, no long-term high temperature aging problem.

●Excellent saturation characteristics.

●Ultra-low DCR/ACR, low loss to achieve high power conversion efficiency

●The bottom electrode structure enables high-density mounting and avoids the risk of short circuits between adjacent devices

Shape and Dimensions

Fig.2

Table.1

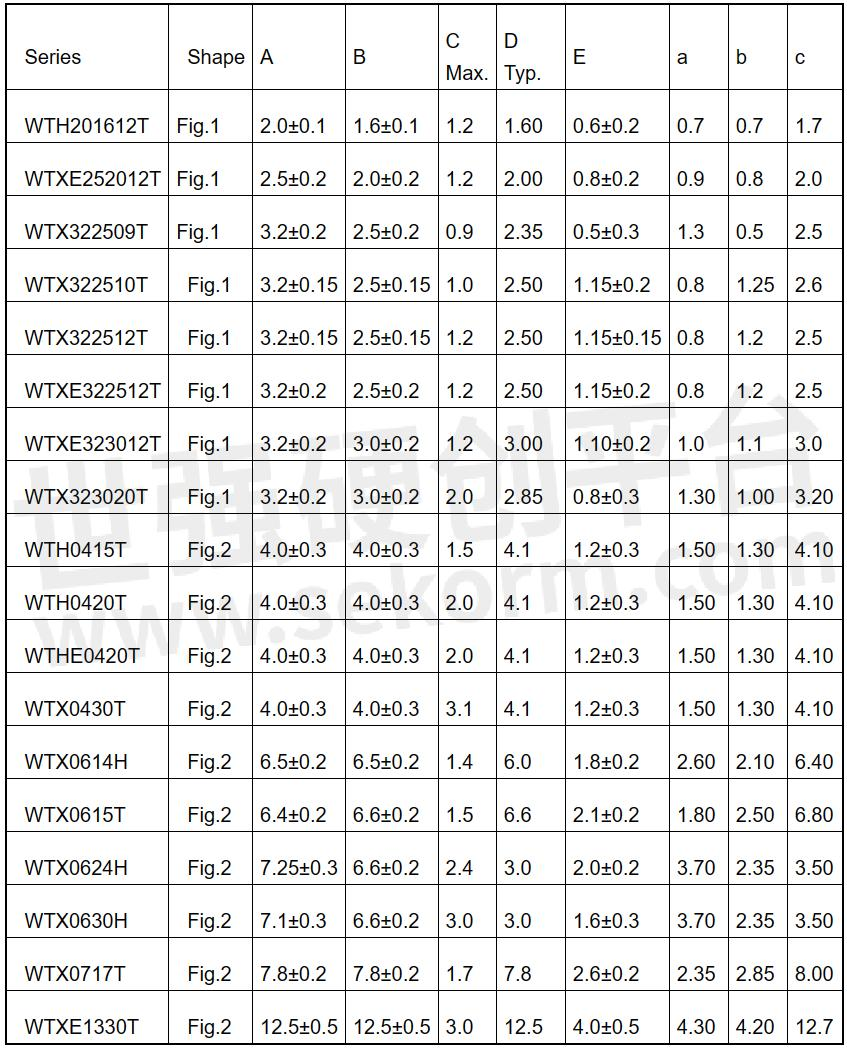

Innovative Technology

Fig.3

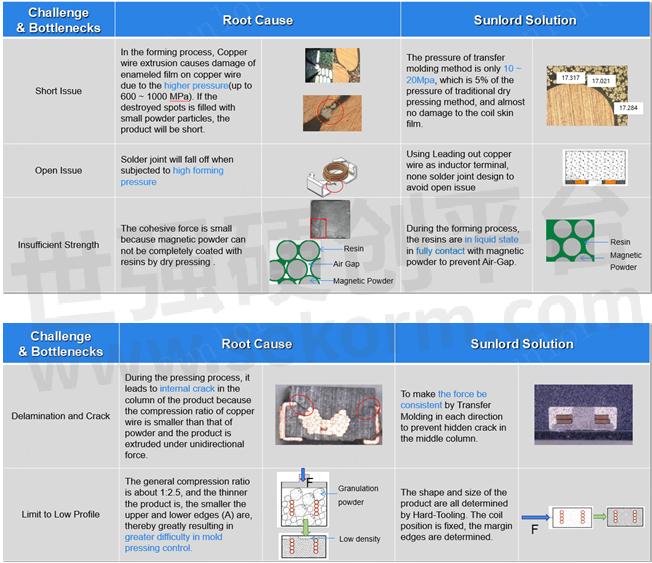

Product Advantages

●Comparison of electrical properties of products

●Compared with traditional molded structure products, WT series inductors have:

●The lowest DCR value was reduced by about 20%~45%;

●Leading saturation current characteristics;

●A more moderate downward trend of the saturation curve.

Fig.4

High-efficiency features

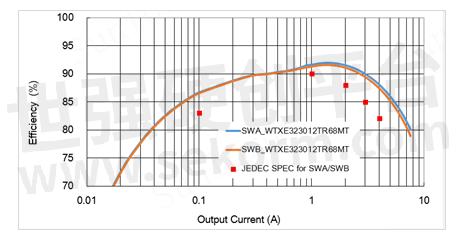

●The efficiency performance of WT series inductors compared to JEDEC.

●Test conditions: The test frequency is 750kHz, RT5136 is an overclocked version test, and the test current reaches 7.5A.

●Test result: Efficiency of SWA/SWB exceeded JEDEC requirements.

Fig.5

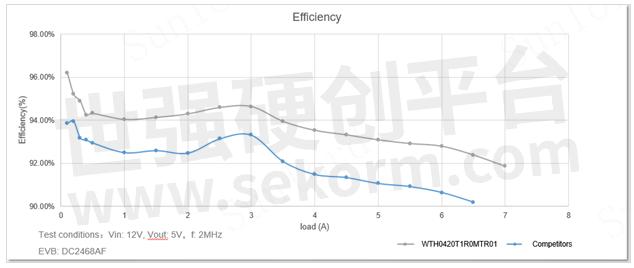

Comparison of conversion efficiency of WT Transfer Molded Power Inductor and traditional molded structure products.

Compared to conventional molded inductors, the conversion efficiency of WT series inductors can be improved by nearly 2% at high loads.

Fig.6

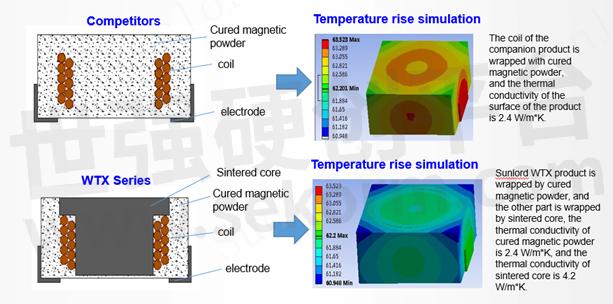

Excellent heat dissipation coefficient

The thermal conductivity of WT series products is better than that of traditional molded structure products, and the surface temperature of WTX is 5% lower than that of traditional products under the same power consumption.

Fig.7

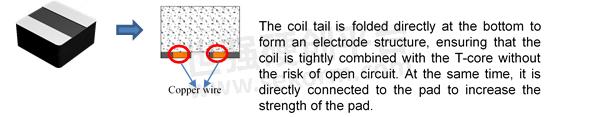

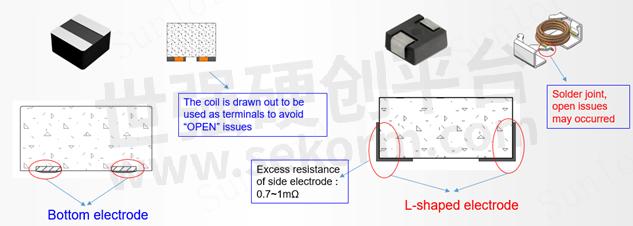

The bottom electrode advantages of molded inductor WT series

High reliability.

The Sunlord WT series molded inductor adopts the Bottom structure. After the coil is drawn out, the tail passes through the bottom of the T-core and then bends, which has integrated the coil and the electrode to improve the reliability of the product. In addition, the bottom electrode can save space and reduce the overall package size during the soldering process with the PCB board.

Fig.8

Lower resistance is possible.

Compared to the L-shaped electrode series, bottom electrode series inductors have 1.4~2.0mΩ lower DCR.

Fig.9

In addition, the WT series has also increased the development of L-type electrodes according to customer needs. This product not only meets high reliability but also has the following advantages: First, the client can directly detect the patch effect through AOI; Second, increase side Sn climbing to improve the terminal strength of the product.

Fig.10

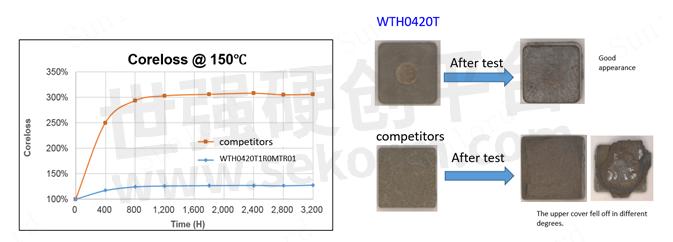

High-temperature stability, the low loss rate of change

After 3200 hours of high-temperature load, the loss of WT series products increases by less than 50%, and no apparent damage; The loss of competitors increased by more than 300%, and the product fell off a large area of magnetic powder.

Fig.11

- 【Datasheet】Wire Wound Molded SMD Power Inductors-WT Series

- 【Datasheet】Wire Wound Molded SMD Power Inductors-WT Series

- 【Datasheet】Wire Wound Molded SMD Power Inductors-WT Series

- 服务器应用程序指南

- SWPA Wire wound SMD power inductor Declaration of Conformity

- 无人驾驶飞行器应用指南

- 小单元应用指南

- 服务器应用指南(Server Application Guide)

- Sunlord's products符合性声明(Declaration of Conformity of Sunlord's products)

- 基站应用指南

- 扫地机器人应用指南

- 无人机应用指南(Unmanned Aerial Vehicle Application Guide)

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.