100 Billion Market Approaching, FATRI Powers New Changes in Smart Wind Power

2022-01-20——"The fierce competition in my country's wind turbine market will start. In the next three years, 2-3 domestic leading wind power equipment manufacturing enterprises will be formed." Li Ye, director of the Energy Conservation and Technology Equipment Department of the National Energy Administration, described my country's wind turbines in the next few years. The main trend of the market: integration, large-scale integration has been carried out among more than 70 wind turbine manufacturers at present! China will have the world's largest wind power market in the future, and fierce competition has already begun. The grand opening of the Beijing International Wind Energy Conference on the 18th verified this conclusion.

The competition of wind turbine companies has entered a white-hot stage, but the operation and maintenance market has just ushered in a golden age. In 2020, the scale of the global wind power operation and maintenance market will increase significantly, exceeding US$17 billion. In the 14th Five-Year Plan, the installed capacity will reach 800 million kilowatts in 2030, and the operation and maintenance of wind power will become a big cake in the era of parity.

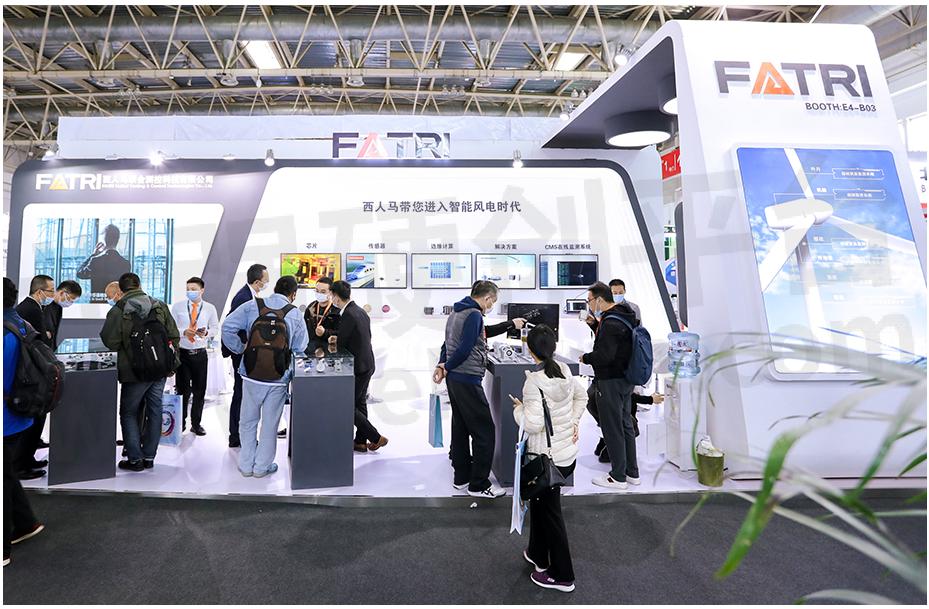

With the continuous development of 5G, artificial intelligence, and industrial Internet of Things technologies, intelligent operation, and maintenance have gradually been put on the agenda. At the Beijing International Wind Energy Conference, dozens of companies demonstrated intelligent operation and maintenance solutions in the wind power field. As an intelligent core hardware supplier in the A-IoT era, the field of wind power is the key service target of FATRI. At this conference, FATRI also brought its own thoughts on the intelligent operation and maintenance of wind power and corresponding solutions.

△All kinds of sensors exhibited by FATRI

FATRI’s smart wind power system, based on advanced sensor technology and edge computing advantages, can monitor the running status of major components of wind turbines in real-time, including online vibration monitoring of wind turbine transmission chains, wind turbine gearbox lubricating oil quality monitoring, wind turbine towers and foundations Condition monitoring, wind turbine blade condition monitoring, etc., early warning of early failure of the wind turbine, making maintenance and repair plans as soon as possible, reducing downtime, and realizing the transformation of wind power failure maintenance and regular maintenance to condition-based maintenance operation and maintenance mode.

△Fallout sales staff negotiate with customers

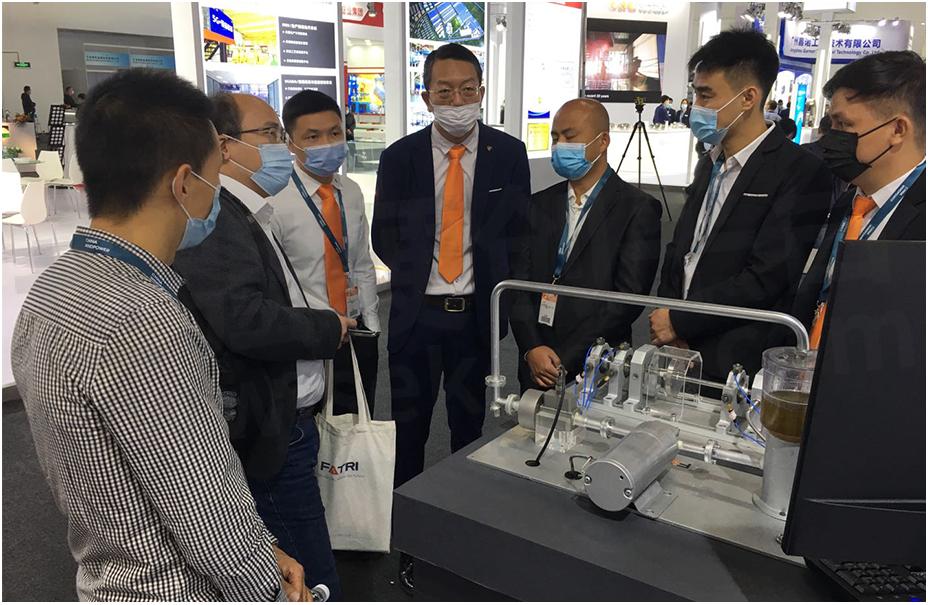

△The staff of FATRI introduced the rotating machinery fault diagnosis and lubricating oil quality monitoring system to customers

This system integrates the current advanced technologies such as the Internet of Things, edge computing, big data, artificial intelligence, etc. The system is modularized, scalable, and configurable as the overall design idea. On this basis, it provides a variety of product forms to meet various needs. Scenario application. It has both data collection and edge computing functions in function, and has the advantages of modularization, easy expansion, and support for secondary development in the application; Enables rapid on-site business deployment.

FATRI Smart Wind Power System Structure

FATRI's smart wind power system includes sensors at the perception layer, data acquisition and edge computing, operator network layer, cloud platform tool suite, and user terminal application layer. Among them, sensors, data acquisition and edge computing systems, and cloud platform tool suites are all independently designed and developed by FATRI and have undergone rigorous performance testing and reliability verification.

End-to-end: multi-state sensing technology for wind power equipment. FATRI is a chip IDM company with a full range of capabilities in the design, manufacture, packaging, and testing of non-silicon & silicon-based chips and sensors. For the wind power field, we have independently developed a variety of sensor products such as transmission chain vibration monitoring, tower slosh settlement monitoring, blade damage monitoring, lubricating oil quality monitoring, and bolt loosening monitoring.

Edge: Edge computing acquisition system, based on a self-developed MCU chip and main control chip, FATRI data acquisition and edge computing system can realize multi-channel and multi-type analog and digital acquisition. The edge computing module adopts high-performance multi-core heterogeneous processors and embeds a variety of algorithm models in the wind power field at the same time, which can process complex algorithms in real-time and perform fault diagnosis, truly realizing the "integration of measurement and control". The modular design makes the system easy to expand and maintain. Users only need a set of edge computing equipment, and by expanding the acquisition module, they can monitor the health status of fans such as CMS, lubricating oil quality, blade cracks, loose bolts, and tower tilt. This avoids repeated investment for wind power owners, greatly reduces later expansion costs, and improves the utilization of space inside the wind turbine. Users can also carry out secondary development of FATRI's data collection and edge computing systems according to their needs so that the products can be more suitable for their own use scenarios and needs, and play a greater value.

Cloud platform: refers to the cloud platform tool suite independently developed by FATRI - Tas Cloud. Tas Cloud is the carrier of online smart monitoring of wind power, and the driving engine of the acquisition layer and aggregation layer. It can realize the visual management of wind farms, early warning of large components, fault diagnosis and analysis, maintenance work order issuance and tracking, expert knowledge base, intelligent Decision-making, and other functional business applications, the platform has the characteristics of tooling and modularization, which ensures the scalability of the business and lowers the operating threshold. The code-free SaaS application development based on drag and drop helps users to quickly generate, debug, and launch industry applications, and finally complete The construction of IoT PaaS core middleware.

Monitoring Scope of FATRI Smart Wind Power System

1. Transmission chain condition monitoring system: It can monitor bearing faults, gear faults, rotor dynamic imbalance, misalignment, mechanical looseness, etc.

The vibration data and status trend of the drive chain of the unit can be monitored in real-time.

Automatically calculate the fault characteristics of the unit components, warn of early faults, and automatically push alarm information.

A diagnostic platform with various diagnostic functions, self-diagnosis functions, various data analysis tools, and graph display and comparison functions.

Diagnostic reports are automatically generated in batches.

2. Blade condition monitoring system: including blade cracks and blade icing, etc.

Real-time monitoring of blade operation status through low-frequency vibration acceleration sensors and acoustic emission sensors.

Supports analysis of blade damage, surface icing, etc. through blade natural frequencies.

According to the built-in algorithm to intelligently warn the blade state change, the warning information is automatically pushed.

Diagnostic reports are automatically generated in batches.

3. Tower status monitoring system

Real-time monitoring of micro-deformation trends such as tower sway through the inclination sensor, and timely detection of deformation and damage of the fan tower.

According to the built-in algorithm, the intelligent early warning tower status changes, and the early warning information is automatically pushed.

Reports are automatically generated in batches.

4. Lubricating oil quality monitoring system

Real-time monitoring of lubricating oil quality, early warning of the deterioration of lubricating oil's own performance.

Real-time monitoring of metal particles and early warning of wear of mechanical parts.

5. Bolt condition monitoring system

Using the modulation effect of vibration on the magnetic field and the principle of piezoresistive effect, the vibration status of the fan tower and the looseness of the flange bolts are monitored.

According to the built-in algorithm, the intelligent early warning bolt state changes, and the early warning information is automatically pushed.

Diagnostic reports are automatically generated in batches.

6. Video surveillance system

It provides a safety guarantee foundation for the comprehensive visualization of wind farms. At the same time, combined with intelligent analysis functions such as intelligent snapshots, it can intelligently monitor wind farm fans, personnel, and equipment in real-time.

Using various comprehensive technical means such as infrared thermal imaging cameras and video intelligent analysis, it can monitor the operating temperature of the large components of the unit in real-time, give real-time alarms to abnormal temperatures, and have a fire alarm function.

The operation control function realizes the monitoring of the wearing of helmets and work clothes of personnel in the operation area and alarms for illegal cross-border behaviors.

7. Fire safety monitoring system

A superfine dry powder device is used for fire extinguishing in engine room space, and an aerosol device is used for electrical cabinet fire extinguishing.

Use temperature-sensing elements, smoke-sensing elements, and thermal elements to start and trigger the fire extinguishing device, and the trigger temperature can be customized.

The unique video infrared temperature measurement function can detect the cabin temperature in real-time, alarm the fire, and trigger the fire extinguishing device.

After the fire extinguishing device is triggered, it will automatically generate a feedback signal to the main control system.

8. Switch cabinet wireless temperature measurement system

Mainly used in medium/high voltage switching power supply cabinets, it is used to monitor the temperature of high voltage switch contacts in real-time, and display it through the always-on LED interface. With a manual setting threshold alarm function, it brings an intuitive and convenient user experience to users.

It adopts CT power acquisition technology, low-power wireless communication technology, and a high-brightness LED cycle display.

Manually set the alarm threshold and buzzer alarm mode, and reserve the RS485 communication interface.

The value of FATRI's smart wind power system

Through the vibration early warning system of condition monitoring, the early failure of key components can be warned, and the abnormal state of the equipment can be predicted in advance, so as to reduce the equipment failure rate and potential safety hazards.

Through the collection, analysis, and calculation of fan operation data, the accumulation of an expert knowledge base is realized, which provides data support for equipment operation and maintenance.

Focusing on fault prediction and remote diagnosis, based on big data, it develops in the direction of intelligence and digitization, and realizes intelligent and less human management of wind farms.

Realize data and resource sharing, effectively improve the production management level, and reduce operation and maintenance costs.

△Guo Yingjun shared FATRI’s smart wind power system at the conference

The battle for intelligent operation and maintenance of wind power has begun. With its advantages in chips, edge computing, and software, FATRI will help more wind power customers enter a new era of intelligent operation and maintenance.

- +1 Like

- Add to Favorites

Recommend

- InvenSense Announces SensorStudio 2.3 Supporting Dataflow-Based Custom Sensors

- Mk20 Series of Cylindrical Reed Sensors, Ideal for Position and Limit Switches, Security, and Level Sensor Applications

- DS Sensors from Elastisense Sensor Technology Are Used to Monitor Longitudinal Expansion and Tilt/angel of The Bridge

- TT Electronics to Feature FlexSense™ and Industry-leading Optoelectronics Portfolio at Sensors Converge 2023

- TT Electronics to Showcase Comprehensive Portfolio of Sensors and Passive Components at Shanghai International Industrial Automation and Robot Exhibition

- TT Electronics to Feature FlexSense™ and Industry-leading Optoelectronics Sensors Portfolio at Sensors Converge 2022

- With FlexSense™ Patented Optical Sensor, TT Electronics Named a 2023 Best of Sensors Awards Finalist

- Bridge Monitoring Made Easy with IBridge Based on ElastiSense Two Sensors DS100

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.