Understanding the Fire Rating & Jacket of Fiber Optic Cable

Fiber optic cable is made up of an inner core, an outer jacket,

cladding, and strengthening material. The shielding and conductors

inside the cable require protection from the jacket since the bare fiber

is readily torn. A fiber cable's first line of defense against

moisture, mechanical damage, flames, and chemicals is its cable jacket.

Material for Fiber Optic Cable Jackets

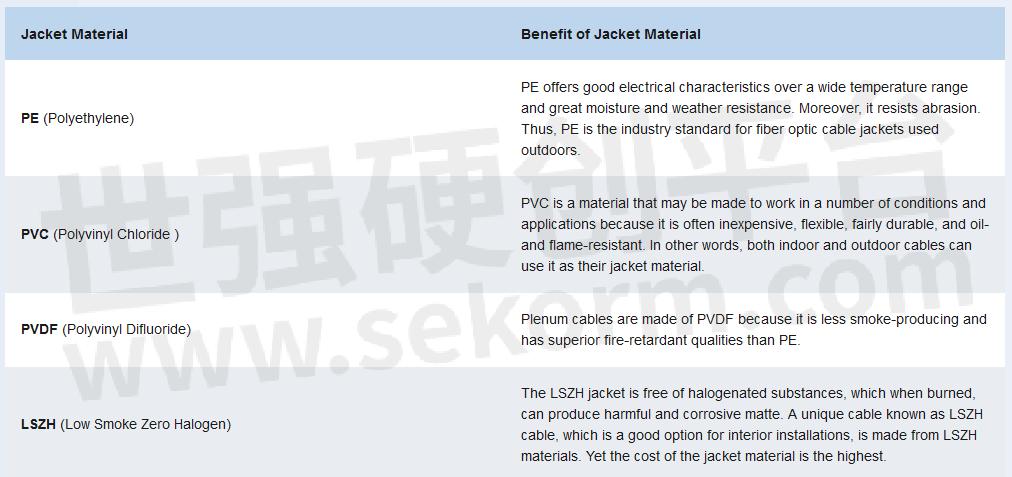

Several kinds of materials are used to make fiber cable jackets. When choosing a jacket type for an application, compatibility with the connections and surroundings is crucial. Some of the most popular fiber cable jacket material types for both indoor and outdoor cables are included in the table below:

Color Code for Fiber Optic Cable Jackets

The

fiber optic cable color code, as defined by EIA/TIA-598, specifies the

jacket color codes for various fiber kinds (SMF or MMF). The jacket

color for single-mode fiber is commonly yellow. Whereas the jacket color

for multimode cable can be orange (OM1 and OM2 cable), aqua (OM3

cable), or purple (OM4 cable). The typical jacket color for wires used

in outdoor plants is black. Please see How to Recognize the Fiber Optic

Cable Color Code for more details regarding fiber optic cable color

codes.

Fire Rating for Fiber Optic Cable

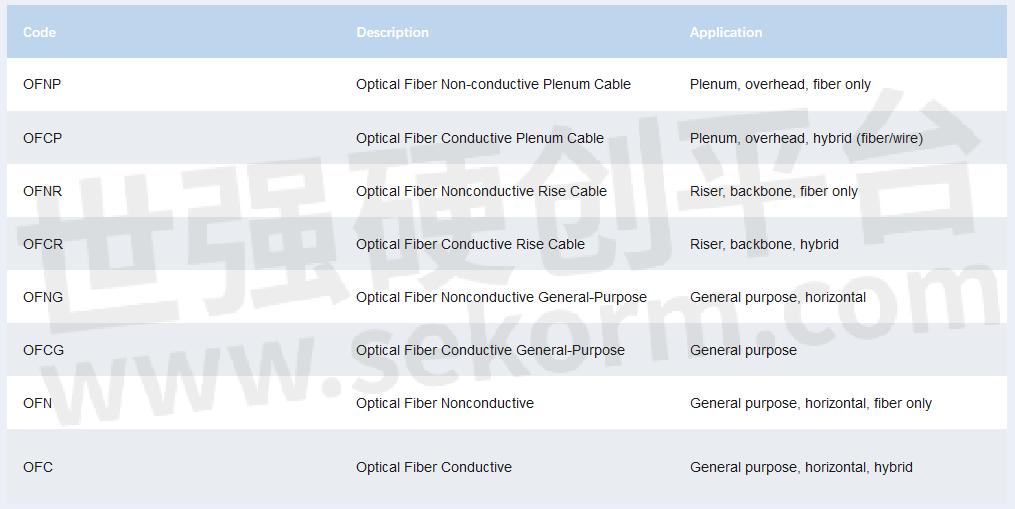

The

NEC typically specifies eight categories of fire resistance for both

conductive and non-conductive wires (National Electrical Code). All

indoor fiber optic cables need to be correctly installed and designated

for their plenums, risers, and general-purpose areas of use.

Note:

(1) A building's plenum area is a room utilized for air circulation or an air distribution system (drop ceiling and raised floors).

(2) A floor aperture, shaft, or duct that extends vertically across one or more floors is referred to as a riser area.

(3) All other space on the same floor that is neither a plenum nor a riser is referred to as a general purpose area.

OFNR versus OFNP

OFNP and OFNR are two varieties of fiber optic cables that are utilized in buildings, as was already explained. OFNP cables offer properties that make them fire-resistant and low-smoke producers. No other cable types can be substituted because this fiber cable has the greatest fire rating. Hence, plenum regions are where these cables are typically put. The fiber resistance and low smoke of OFNR cables, however, are inferior to those of OFNP. OFNR cables can be replaced by OFNP plenum cables. It is important to note that while comparing OFNR with OFNP, the former can be utilized in riser areas, whilst the latter cannot be used in plenum areas. OFNP and OFNR can both be utilized for general purposes.

T&S Plenum/Riser Fiber Optic Cable Solutions in a nutshell, plenum-appraised and riser-appraised cables are for the most part conveyed inside the buildings. Choosing the correct sort of appraised cables can successfully decrease loss when the cables are burning. In case your cabling application requires materials that are flame-retardant or compliant with strict safety guidelines, it would be ideal if you continuously prefer plenum-rated cables.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.