Ultra-large Current Assembled Power Inductor of TLVR-WPZ Series Provided 0906/1206/1205mm Products

The WPZ series of assembled inductors for ultra large current TLVR applications adopt a fully automatic assembly process. Through the use of ultra-low loss magnetic materials and a patented insulation design process, it can achieve higher saturation current and more accurate inductance controlling in similar products of the same size. At the same time, its insulation capacity also ranks high among similar products.

In general, it has the characteristics of ultra-low loss, ultra-high current, ultra-low DCR, low leakage inductance, etc. At the same time, SUNLORD has the advantage of an automatic production line, which makes its products have incomparable advantages in consistency. At this stage, the conventional 0906/1206mm products in the market can be provided. For the first time, in order to cope with the latest power stage, new 1205mm products have also been introduced.

It can be applied to TLVR power supply applications of various X86 servers in the market, as well as TLVR application requirements of other architecture servers. It is mainly used for power supply scenarios such as servers and GPU cards.

Background

Previously, CPU power consumption was only 165W, and VRM power supply mode was 6-phase. Therefore, the structure of the horizontal air gap is dominant.

Now, the CPU power consumption exceeds 200W, which puts forward higher requirements for the heat dissipation capacity and efficiency of the inductor.

As a result, the vertical air gap structure has been developed and widely used. But still in VRM mode.

In the future, based on the requirements of server manufacturers to improve efficiency and reduce costs, the concept of TLVR will emerge as the times require. It has the obvious advantages of fast transient response, reducing the number of back-end capacitors to reduce costs, and has won the favor of major manufacturers.

Among them, the special coupling inductor and compensation inductor of TLVR occupy the key position.

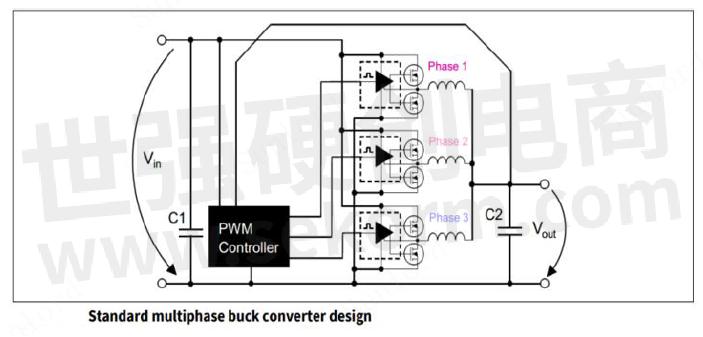

Fig.1

TLVR Technology Overview

●Server power supply modes include VRM power supply (previous technology) and TLVR power supply (new power supply technology)

VRM power supply mode:

Fig.2

Image source: Infineon DCDC_Converter_How_Infineon _TLVR_solves_PDN_problem-ApplicationNotes-v01_00-EN

●Features: Each phase can be regarded as a separate Buck circuit, and then the output current is summarized as the total current.

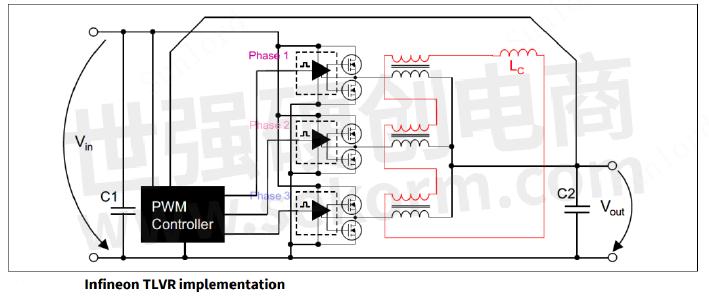

TLVR power supply mode:

Fig.3

(Image source: Infineon DCDC_Converter_How_Infineon _TLVR_solves_PDN_problem-ApplicationNotes-v01_00-EN)

Note: Different from VRM power supply, TLVR power supply requires an additional Lc compensation inductor in addition to the coupling inductance at the original position.

Features: Each phase is connected in series by the coupled inductor to transmit instantaneous load information to each other while providing additional energy with the aid of a compensation inductor.

Advantage:

●Thanks to the power compensation of the Lc compensation inductor, the capacitance value of the output capacitor decreases, thereby reducing the price

●Fast transient response speed, reducing CPU power ripple

●Improve conversion efficiency

Features

● Effectively improve the withstand voltage value (meet the specification of 100Vdc/2S/2mA, meanwhile, it can be increased to 200Vdc/2S/2mA)

●Fully automatic production line with high consistency

●High saturation and high-frequency magnetic materials are used to reduce AC loss and effectively improve conversion efficiency.

Applications

●TLVR power supply for server CPU, GPU, FPGA, etc

Dimensions

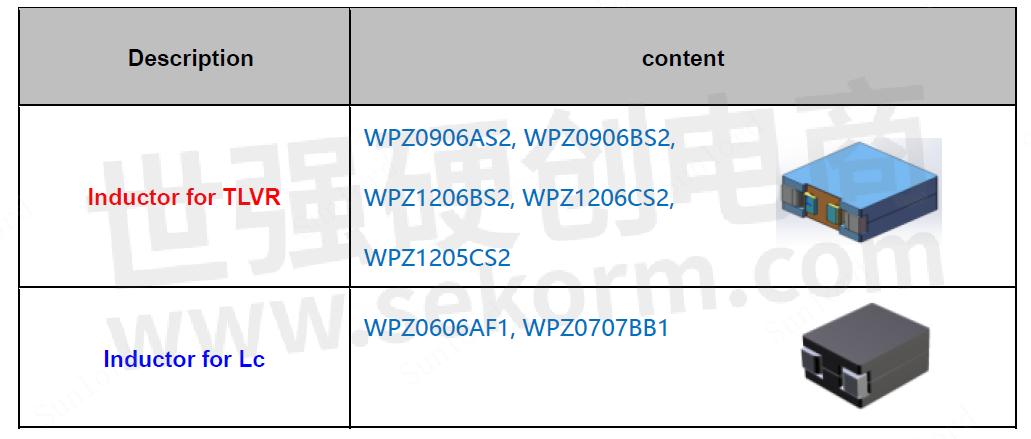

●Summary of WPZ series for Sunlord TLVR application

●It has a single coil of WPZ0906AS1 that can meet the requirements of VRM and TLVR on the same PCB with WP●Z0906AS2 because of their compatible soldering pad.

●With WPZ1206CS2 and WPZ1205CS2 series TLVR products that can pin-to-pin with each other

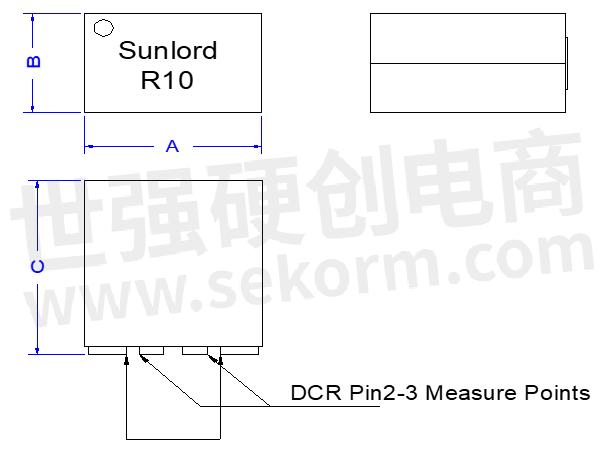

●Product size (A * B * C)

Table.1

WPZ0906AS2: 9.3x6.1x9.7mm

WPZ0906BS2: 9.3x6.1x11.1mm

WPZ1206BS2: 11.7x5.7x10.7mm

WPZ1206CS2: 11.7x5.7&5.8x11.8mm

WPZ1205CS2: 11.7*4.7&4.8*11.8mm

Fig.4

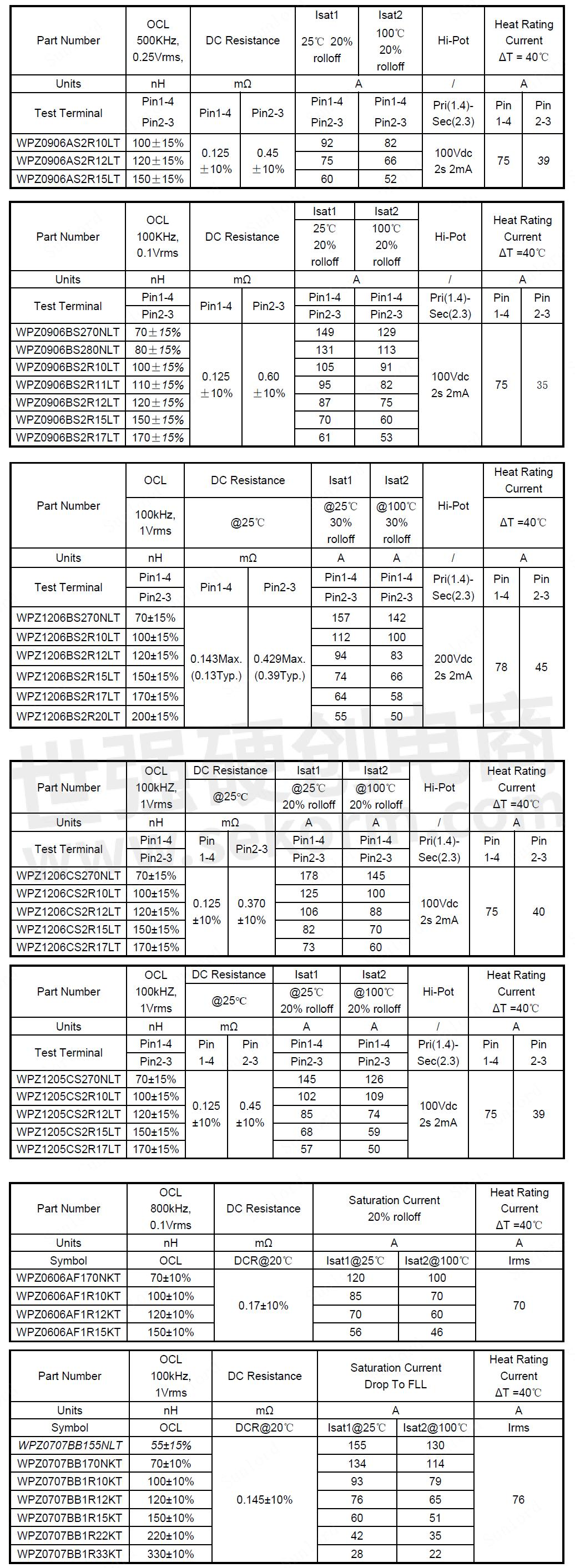

Ultra-large Current Assembled Power Inductor Part Number

Table.2

Production

●The sample can be sent at any time

●Mass production import stage

- 【Datasheet】WPZ Series Ultra-largeCurrent Assembled Power Inductor of TLVR New Product Launch

- 【Datasheet】WPZ Series Assembled SMD Power Inductors

- 【Datasheet】Assembled SMD Power Inductors – WPZ Series

- 【Datasheet】WPZ Series Assembled SMD Power Inductors

- 【Datasheet】WPZ Series Assembled SMD Power Inductors

- 【Datasheet】Assembled SMD Power Inductors – WPZ Series

- 服务器应用程序指南

- 服务器应用程序指南

- 基站应用指南

- 游戏机应用指南

- 小单元应用指南

- SWPA Wire wound SMD power inductor Declaration of Conformity

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.