ATP Offers Typical SSD Form Factors, NAND Flash Technologies and Interfaces

Getting to Know the SSD Inside Out

In enterprise data centers and industrial environments where workload demands are high and the speed of data access is crucial, solid state drives (SSDs) are increasingly becoming the storage of choice.

What is an SSD? How can you choose the right SSD for your project to yield reduced total cost of ownership (TCO)? First, let us look under the hood and see what makes it work.

The Inside Story

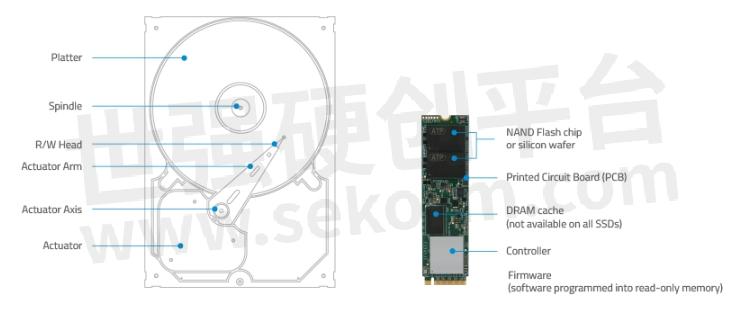

An SSD and a hard disk drive (HDD) serve similar purposes— they are storage devices. Unlike an HDD, however, an SSD has no moving parts. It does not save data on magnetic platters, and there is no head rotating over the platters to read or locate data.

What is inside an SSD and how does it do what it is supposed to do?

Flash Controller

The flash controller is the heart and brains of the SSD. It is responsible for interfacing with the host computer and the other components of the SSD. When a host computer wants to send data to the SSD, the flash controller directs the flow of data to ensure its reliable storage and retrieval. It also contains the firmware that manages the SSD and performs background processes such as managing the flash file system, wear leveling, error correction, trim, and garbage collection.

This is a small amount of memory that is used as temporary storage of data. It is not available in all SSDs. Because it is volatile, it requires power to retain information. Firmware in the controller decides when to flush or move the data from volatile (non-persistent) memory to the non-volatile (persistent) flash memory. In the event of an unexpected power loss, data in the cache could be lost or corrupted unless an effective power failure protection mechanism is available.

Non-Volatile NAND Flash Memory

Data is persistently stored in and retrieved from NAND flash memory chips. They are non-volatile because they retain data even when there is no power to the SSD.

Figure 1. Main components of an HDD and SSD. (Images are not to scale.)

NAND Flash Memory Types

NAND flash memory is essentially categorized based on how much information each chip can store. Single level cell (SLC) stores only one bit of information on each cell. Multi-level cell (MLC) holds more than one bit of information, though it is commonly associated with two-bit memory. Triple level (TLC) and quad level (QLC) cells, as the names imply, store three and four bits respectively. For a comparison of the main NAND flash types, please click here.

On top of the standard types of NAND flash memory, ATP implements a new advanced firmware technology called "SLC Mode," which allows MLC flash to act as SLC at accessible price points without compromising performance, endurance, capacity and data retention.

Beyond Conventional NAND Flash Labels

The more bits a cell can hold, the bigger the storage capacity. It is common to think that as more bits are crammed into a cell, error rates also increase, causing reliability and longevity to decrease. However, thanks to major headway in storage technology, people are no longer sticking to conventional labels. Economical options that were once relegated as mediocre choices can now have better performance, longer endurance and greater reliability due to powerful controllers, advanced firmware, robust error correction mechanisms, and meticulously screened components, along with stringent testing, validation and manufacturing practices.

ATP builds its products from the ground up, thoroughly screening components from the wafer and IC level to packaging and design all the way up to device/module level testing and validation, so customers can have peace of mind that only the choicest, premium products come out of ATP's manufacturing facilities. All ATP products are made for mission-critical applications where high levels of performance, reliability and endurance are required while maintaining low TCO and generating high returns on investment (ROI).

Getting Connected

An SSD connects to the host using an "interface," which adheres to a specific "protocol." Interface refers to the hardware transportation layer including voltage, current, and physical pin definition, while protocol refers to the set of rules, standards, command sets and drivers between the storage and the operating system. The choice ofinterface will determine the amount of data that can be transmitted within a period of time (bandwidth), the delay before data transfer actually begins after the transfer instruction is sent (latency) and the capability to expand the system or network to adapt to growing workloads (scalability). It will also determine whether your SSD will have hot-swap or hot-plug capabilities. All of these are important considerations in enterprise usage.

Briefly described below are commonly used SSD interfaces.

Serial ATA (SATA)

SATA is currently the prevalent interface for connecting an SSD to the host. It affords the convenience of being used interchangeably with SATA-based HDDs. Transfer rates for first-generation SATA began at 1.5 Gb/s, and the latest generation, SATA revision 3.0, provides a native transfer rate of 6 Gb/s. SATA uses the Advanced Host Controller Interface (AHCI) command protocol, which was designed for slower mechanical drives with spinning disks.

PCI Express® (PCIe®)

Though PCIe was originally designed as an interface for linking motherboard-mounted peripherals like graphics or wireless network cards, its excellent features for scalability, minimal latency, high bandwidth, and high performance makes it an emerging interface favorite, enabling SSDs to blaze past the SATA III limitation of 6 Gb/s transfers. The interface specification optimized for NAND flash and next-generation solid-state technologies is known as NVM Express® or NVMe™. NVMe delivers twice the performance of SAS 12 Gb/s and four times the performance of SATA 6 Gb/s.

Serial Attached SCSI (SAS)

SAS is designed for high-performance enterprise requirements and is backward compatible and interoperable with earlier SCSI technologies as well as SATA, so a SATA drive can be attached to a SAS port; however, a SAS drive cannot be plugged into a SATA port. SAS doubles the SATA transfer rate (up to 12 Gb/s), delivers better data integrity than SATA, and supports dual-port operation.

Form Follows Function

"Form factor" refers to the size and physical configuration of a device. Initially, SSDs were seen as HDD replacements and came in HDD sizes such as 1.8", 2.5", 3.5" and 5.25". In late 2010, SSDs consisting of flash chips and controllers attached to a circuit board were used in ultra-thin mobile computers. These SSDs were long, thin and narrow, and had no enclosure. Choosing the right form factor is important, as it defines whether it fits in the system chassis, how many can fit, and if it can be replaced without powering off the system (hot-plug/hot-swap functionality).

Below are typical SSD form factors available from ATP.

Traditional HDD Sizes

SSDs with enclosure come in 1.8" for removable ultra-mobile applications, 2.5" and 3.5" for desktop and enterprise systems, and the less common 5.25" for special-purpose appliances like backup devices. ATP's 2.5" industrial SSDS with the SATA III 6 Gb/s interface are shock resistant and can operate in a wide range of temperatures, making them ideal for enterprise and industrial applications requiring outstanding performance, endurance and reliability amidst rigid operating conditions.

Solid State Modules

M.2 NVMe

M.2 SATAs

Flash memory chips reside in a dual in-line memory module (DIMM) or similar form. They may use a standard HDD interface like SATA.

The M.2 standard provides higher performance and capacity while minimizing module footprint. M.2 modules connect either via SATA or PCIe, come in multiple widths and lengths, are available in soldered down or connectorized type, and can have single- or double-sided components. All soldered down modules are single-sided and are intended to be used in low-profile applications. (Note: M.2 modules are neither hot-swappable nor hot-pluggable.)

ATP M.2 NVMe SSDs fit into a PCIe 3.0 x4 slot, offer up to 1 TB capacity, and deliver a bandwidth of up to 32 Gb/s (8 Gb/s per lane), which is four to six times the data transfer speed of the previous-generation AHCI protocol on Serial ATA drives.

ATP M.2 SATA SSDs deliver high-performance SATA 6 Gb/s and adopt the double-sided configuration to enable higher densities. They come in three sizes: 2242, 2260 and 2280.

mSATA

Just roughly the size of a business card, an mSATA SSD adopts the PCI Express Mini form factor and connector. Though it can easily be mistaken for a PCIe mini card, an mSATA SSD signaling conforms to the mSATA standard, which is based on the SATA storage interface supporting maximum data transfer rates up to 6 Gb/s. It plugs into an existing PCIe Mini card slot but will function properly only if connected to a SATA host controller. Compatible slots will be labeled as either dedicated for mSATA or shared with PCIe mini. A PCIe Mini card installed on a dedicated mSATA slot will not function properly.

SlimSATA

Also called Half-Slim SATA, a SlimSATA SSD uses a 22-pin SATA pin connector, the same connector used on 2.5" SSDs. ATP SlimSATA SSDs are high-performance and reliable mass storage devices featuring an advanced wear-leveling algorithm for enhanced endurance.

Flash Memory cards

Memory cards also use flash memory and are used either as removable or embedded storage. ATP's industrial flash memory cards are built for rigorous computing conditions in automotive applications and industrial environments. They feature advanced wear leveling and data integrity protection features and can withstand harsh operating environments with severe temperatures ranging from -40℃ to 85℃. Flash memory cards in ATP's portfolio include SD/SDHC/SDXC, microSD/microSDHC/microSDXC, CFast, and CompactFlash (CF) cards.

Embedded USB (eUSB)

An embedded USB module complies with the Universal Serial Bus (USB) standards. It is commonly used as a boot drive for systems and applications. ATP eUSB modules are ideal for industrial and rugged environments. Advanced wear leveling ensures long usage life and ATP PowerProtector completes the last read/write operation during a sudden power loss event, so data is safely stored to the NAND flash.

A USB drive, also known as a USB stick, thumb drive, pen drive, or USB flash drive is a flash-based storage device that connects to the host via a USB interface. While commonly used as external removable storage, USB drives are now also being used in embedded industrial applications, mainly as boot drives. ATP Nanodura ruggedized industrial USB drives are suitable for mission-critical computing with their tough metal housing, which enables them to withstand extreme temperatures from -40°C to 85°C as well as resist water, moisture, dust, shocks, vibration, electrostatic discharge and other environmental strains.

ATP Advantages

While it is common and helpful to choose SSD solutions based on NAND flash types, capacities and interfaces, endurance and reliability must also be considered to guarantee dependable operation over long periods of time. In industrial applications, devices often function under heavy workloads, extreme temperatures and harsh environments with dust, humidity and other external hazards. It is therefore important to go for a trusted manufacturer that takes control of every manufacturing process to ensure quality and steady supply.

As an established memory and storage manufacturer with over 25 years of expertise, ATP is committed to the highest quality of products and services. Here are their key differentiators

Strategic Partnerships ensure product longevity, supply stability, technical support, and smooth qualifications and transitions.

Process Ownership. ATP maintains complete control of its supply chains and takes charge of all stages of the manufacturing process from NAND characterization, wafer management, package-level validation and NAND flash screening all the way up to mass production.

NAND Self-Packaging Capability using high-quality Full-Grade ICs sourced 100% from Tier 1 manufacturers.

Rigorous Testing and Validation from IC to Module and MP Levels ensure the reliability of all flash products.

ATP-Owned Manufacturing Facilities with state-of-the-art production, testing and inspection equipment.

- +1 Like

- Add to Favorites

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.

Recommend

ATP SATA SSDs Qualify for Compatibility and Interoperability with Microchip‘s New Tri-Mode Storage Adapters

2021-10-22 - Manufacturer News ATP ELECTRONICS has announced that its A600Sc Series serial ATA solid state drives (SATA SSDs) have been successfully qualified for compatibility and interoperability with Adaptec® Smart Storage PCIe® Gen 4 Tri-Mode SmartRAID 3200, SmartHBA 2200, and HBA 1200 Smart Storage adapters.

The ATP Gym and Coach System: Exercising SSDs to Ensure Total Fitness

2021-05-27 - Manufacturer News With the Gym and Coach system, ATP has dramatically improved RDT and the initialization process for functional test details. By making industrial SSDs undergo a lot of “painful” exercises through stringent testing, ATP makes sure that customers have everything to gain by receiving the most robust, reliable and enduring flash storage products for their applications.

ATP Launches Customizable SecurStor microSD Cards with Secure Boot and HW AES-256 XTS Encryption

2021-04-24 - Manufacturer News ATP Electronics, the global leader in specialized storage and memory solutions, has launched the SecurStor microSD cards – the latest in its line of secure NAND flash storage products for the Internet of Things (IoT), education, automotive, defense, aerospace and other applications requiring confidentiality and reliability.

The Most Reliable SSD For Industries

Company profile 3D NAND SSDs and Emergent Technologies Cloud/Defense Series SSD Featured Technologies Applications PCIe SSD SATA 2.5" SSD SATA M.2 SATA MO-276 / MO-297/ MO-300 SATA 7-pin Module Industrial CF/CFast/SD/microSD Card Industrial USB Drive Disk Module

20220422 - Selection guide SATA 7-PIN MODULE,3D NAND SSDS,工业MICROSD卡,工业SSD,NGSFF(M.3) SSD,INDUSTRIAL MICROSD CARD,云SSD,工业U盘模块,工业CF卡,EDSFF SSDS,工业CFAST卡,工业USB驱动器,PATA SSD MODULE,PCIE BGA固态硬盘,SATA 7引脚模块,NGSFF SSDS,EDSFF SSD,工业SD卡,SATA 2.5" SSD,磁盘模块,3D NAND固态硬盘,PCIE SSD,PCIE固态硬盘,NGSFF(M.3)SSD,SSD,SSDS,CLOUD SSD,INDUSTRIAL USB DRIVE,SATA 2.5英寸SSD,3D NAND FLASH MEMORY,INDUSTRIAL SSD,NGSFF固态硬盘,PATA固态硬盘,PATA SSD,PATA DISK MODULE,NGSFF SSD,APACER SATA 2.5" SSD,EDSFF固态硬盘,PCIE BGA SSD,固态硬盘,INDUSTRIAL CF CARD,INDUSTRIAL SD CARD,国防SSD,DEFENSE SSD,DISK MODULE,INDUSTRIAL CFAST CARD,INDUSTRIAL USB DISK MODULE,UV110-UFM2,SDM7-M 7P 180D LP2H,UV110-UFM1,SM22P-CFAST,SDM5A 7P/180D LP2,US120-UFD5,SM21P-25,UV110-UFD5,SV25C-M242,INDUSTRIALSD R1,EH353-M,PT220-M280,UDM2A-M,SDM5A-M 7P/90D LP,SH250-M280,SV250-CFAST,SDM5A 7P/180D SLIM2,PV930-M280,SDM5A 7P/90D LP,SU210-25,CF6,CM710-CF,PV210-M280,SDM5A-M 7P/180D SLIM2,INDUSTRIAL MICROSD R1,SV25C-25,ST250-300,INDUSTRIAL SD H1-SL,SH24D-M280,SV250-25,SH250-25,SM230-M280,UH110-UFM1,SH24D-25,SU230-CFAST,SH250-300,SDM5A-M 7P/180D SLIM2H,ADM5S-M,SV170-ΜSSD,CS710-CF,SV250-M242,EH353,SDM5A 7P/90D LPH,PV220-M280,UDM 1U-M,PV140-25,ST250-M280,CF6A,PV910-M280,SH24D-300,ADM5S,INDUSTRIAL SD H1-M,SDM5A 7P/180D SLIM2H,ST250-25,PV920-M280,SV25C-M280,SDM7-M 7P/180D DP,SDM7-M 7P 180D LP2,SS210-300,SS220-M242,AH322,SH250-CFAST,EH163-M,AH321,UDM2A,SDM5A-M 7P/180D LP5,SH250-M242,INDUSTRIAL SD,SDM5A-M 7P/90D LPH,UH110-UFD4,SU220-CFAST,UM120-UFD5,SV240-297,INDUSTRIAL MICROSD H1-M,SDM5A-M 7P/180D LP5H,AFD257-M,CV110-MSD,CH110-MSD,SV250-7LP2/180D,SV25C-300,SM210-25,CH110-SD,SV250-300,ST250-M242,USZ20-UFD5,CV110-SD,SV240-M280,CH710-CF,AFD257,SV240-300,SS220-CFAST,PH920-M280,SV250-M280,SM230-CFAST,SS210-25,SLC-LITEX,SM230-M242,CH120-MSD,INDUSTRIAL MICROSD H1-SL,CF6-M,SM210-M280,PV22D-M280,CF6A-M,UV110-UFD1,UDM 1U,PV910-M242,PV910-CFX,INDUSTRIAL MICROSD,SV240-25,ST250-297

2023 Product Catalog: We build With you-The Global Leader in Specialized Storage and Memory Solutions

Company Profile Segment Challenges and Solutions Thermal Solutions Endurance Solutions Security Solutions CFexpress & USB 3.0 Value Line SSDs DDR5 DRAM SOLUTIONS FLASH SOLUTIONS Flash Products Naming Rule Solutions & Technologies Flash Technology Overview table Complete Flash Spec Overview & Product Dimensions

012023 - Selection guide ECC SO-DIMM,USB驱动器,MICROSD MEMORY CARDS,MICROSDHC CARD,DDR SO-DIMM,3D TLC SSDS,PCIE®GEN4高容量NVME M.2 2280固态硬盘,PCIE® GEN4 NVME U.2 SSD,SATA III 2.5" SSD,DDR2模块,PCIE® GEN 4 NVME M.2 2280 SSD,SD CARD,SATA III M.2 2280 SSD,PCIE®GEN4 NVME U.2固态硬盘,PCIE® GEN 3 NVME M.2 2280 SSD,NANODURA双通用闪存驱动器(UFD),PCIE®GEN 3 NVME M.2型1620 HSBGA固态硬盘,SD CARDS,CFEXPRESS TYPE B MEMORY CARDS,DRAM,非ECC UDIMM,NVME固态硬盘,SECURSTOR MICROSD CARD,DDR2 MODULES,DDR4 RDIMMS,SATA III MSATA SSD,SSDS,PCIE® GEN 3 NVME M.2 2242 SSD,SD卡,LEGACY (SDR/DDR) DRAM MODULES,ECC UDIMM,NON-ECC UDIMM,PCIE® GEN4 NVME CFEXPRESS CARD,NANODURA双UFD,PCIE® GEN 3,PCIE® GEN 3 NVME M.2 TYPE 1620 HSBGA SSD,SDHC CARD,E.MMC,HIGH-SPEED TYPE B CFEXPRESS CARDS,高速B型CFEXPRESS卡,PCIE® GEN4 HIGH-CAPACITY NVME M.2 2280 SSD,DDR3模块,DDR5 DIMM,MICROSD卡,PCIE®GEN3 NVME U.2固态硬盘,SOLID STATE DRIVES,SDXC卡,DRAM MODULES,SATA III M.2 2242 SSD,PCIE® GEN3 NVME M.2 2242 SSD,NON-ECC SO-DIMM,DUAL-INLINE MEMORY MODULES (DIMMS),CFAST卡,NVME散热器球栅阵列(HSBGA)固态硬盘,PCIE®GEN 3 NVME M.2 2242固态硬盘,SD MEMORY CARDS,MICROSD CARDS,非ECC SO-DIMM,PCIE®GEN 3 NVME M.2 2280固态硬盘,SDHC卡,DDR3 UDIMM,DDR3 MODULES,PCIE® GEN3 NVME M.2 2280 SSD,存储卡,固态硬盘,DDR3 MODULES,SECURSTOR MICROSD卡,MICROSDXC CARD,DDR3 SO-DIMM,NAND FLASH MEMORY,PCIE® GEN3 NVME M.2 2230 SSD,DDR4模块,DDR5 MEMORY,DDR5 DIMMS,WIDE TEMPERATURE RDIMM,HSBGA SSDS,NVME HEAT SINK BALL GRID ARRAY (HSBGA) SSDS,DDR4-3200模块,SDXC CARD,NANODURA DUAL UNIVERSAL FLASH DRIVES (UFDS),SATA III 2.5英寸固态硬盘,DDR4-3200 MODULE,RDIMM,MICROSDHC卡,PCIE® GEN 3 NVME M.2 2230 SSD,DDR4 MODULES,DRAM模块,DDR4宽温度RDIMM,MICROSDXC卡,NVME SSDS,DDR5内存,MEMORY CARDS,NVME M.2 TYPE 1620 HSBGA SSD,SDRAM,DDR5模块,CFEXPRESS CARDS,DDR UDIMM,SATA III M.2 2280固态硬盘,UNIVERSAL FLASH DRIVES,PCIE® GEN3 NVME U.2 SSD,NANODURA DUAL UFDS,DDR1模块,DDR1 MODULES,U.2 SSD,MICROSD CARD,PCIE® GEN3 NVME,USB DRIVES,SOLID STATE DRIVES,SSD,DDR5 MODULES,NAND型闪存,DDR4 RDIMM,COMPACTFLASH CARD,DDR4 WIDE-TEMP RDIMMS,3D TLC固态硬盘,COMPACTFLASH卡,PCIE®GEN4 NVME CFEXPRESS卡,CFEXPRESS B型存储卡,CFAST CARD,PCIE®GEN 3 NVME M.2 2230固态硬盘,SDRAM SO-DIMM,PCIE®GEN 4 NVME M.2 2280固态硬盘,PCIE® GEN4 NVME M.2 2280 SSD,HSBGA固态硬盘,SATA III M.2 2242固态硬盘,A750PI,E650SC SERIES,S600SC,B800PI,S750 SERIES,S600SI,S600SCA,E750PC SERIES,B600SC,N700PC,S700SC,E650SC,A750 SERIES,E600VC,S800PI,A750PI SERIES,I800PI,A600VC,A650SI,A650SC,N700 SERIES,S650SI,N750,N750PI,A800PI,A700PI,N700SI,N650 SERIES,E600SAA,N700SC,A750,N600SC,A600VC SERIES,E600SA,E650SI,E650SI SERIES,N750 SERIES,E700PIA,TR-03153,N600SI,S650,S650SC,E700PAA,N650SIA,E600SI,B600SC SERIES,S750SC,S600SIA,I700SC,N650SI,N600VI,E600SIA,E750PI,N650SC,N750PI SERIES,N600VC,I600SC,E750PC,S700PI,A650 SERIES,N650,N600 SERIES,N600VC SERIES,S650 SERIES,A650,AES-256,E700PI,A600SI,E750PI SERIES,N700PI,E700PA,S750,S750PI,E700PC,A600SC

AceTT: Conquering Digital Deserts With up to 18 Stages of Thermal Throttling

2025-09-28 - Technical Discussion By achieving thermal equilibrium, AceTT prevents SSDs from overheating, extends their lifespan, and ensures reliable operation in demanding conditions, especially in mission-critical environments where consistent performance and long-term reliability are essential.

SMART New M.2 2242, mSATA and Slim SATA Offer Options for a Wide Range of Applications

2021-09-15 - New Product Introduction SMART Modular Technologies has expanded its DuraFlash™ ME2 SATA SSD product family with the addition of M.2 2242 SATA, mSATA (MO-300A) and Slim SATA (MO-297A) that complement the current M.2 2280 and 2.5” SSD form factors in SMART’s DuraFlash portfolio.The new ME2 SATA SSD form factors are ideal for embedded computing, transportation, medical and industrial applications that require either smaller or legacy SSD form factors. Built with Triple-Level Cell (TLC) 3D NAND technology, they are available in both commercial (0 °C to 70 °C) and industrial (-40 °C to 85 °C) operating temperatures.

Designed Solutions Driven by Innovation Flash Storage Products

Company Portfolio/Products Applications Flash Storage Product Introduction 2.5” SATA M.2 SATA mSATA Slim SATA M.2 PCIe NVMe U.2 PCIe NVMe EDSFF / U.2 PCIe NVMe (Enterprise and Data Center SSDs) BGA eMMC 5.1 Memory Cards CF Cards/CFast Cards eUSB Flash Drives/USB Flash Drives RUGGED SSD LINE-UP

08.27.21 - Selection guide USB FLASH DRIVES,MICROSD CARDS,SD CARDS,M.2 2280 PCIE NVME,EMBEDDED SSDS,ENTERPRISE AND DATA CENTER SSDS,MSATA,M.2 PCIE NVME MODULE,固态驱动器,CFAST CARDS,USB FLASH DRIVES,BGA EMMC 5.1,MICROSD卡,SD CARDS,SOLID STATE DRIVES,SLIM SATA,CF CARDS,CF卡,CFAST卡,M.2 2280 SATA,MICROSD CARDS,SSD,M.2 PCIE NVME,M.2 PCIE NVME模块,M、 2个SATA,EUSB闪存驱动器,CFAST,ENTERPRISE/DATA CENTER SSD,2.5” SATA,MEMORY CARDS,EUSB,EMMC,SD CARDS,SD卡,存储卡,CFAST CARDS,EUSB FLASH DRIVES,固态硬盘,USB闪存驱动器,U.2 PCIE NVME,CF CARDS,EDSFF,2.5英寸SATA,NVME MODULES,超薄SATA,M.2 SATA,N200,R800,RU350,SP2800,S5E,RU150,T5E,M4,R800V,BGAE440,S1800,BGAE240,RD130M,ME2,M1HC,H9 CF,M1400,HU250E,M4P,T5EN,T5PFL,RU150E,N200V,T5PF,RD230M,MDC7000,XL+,RD230

Data on the Edge: Requiring A New Breed of SSDs Where Traditional Solutions No Longer Suffice

2025-09-18 - Product Introduction Edge computing refers to the processing and storage of data closer to the source, as opposed to centralized repositories like data centers. It enables data to be kept closer to its source or the network‘s edge. It speeds up access, processing, and response time by reducing the distance that the data must travel.

NVMe SSD Thermal Management: What We Have Learned from Marathons

2024-05-24 - Design Article NVMe solid state drives (SSDs) are known to run at blistering speeds. They are 4X faster than Serial ATA (SATA) drives! As such, they are prone to overheating, especially when installed in systems with limited airflow. This series of articles explores the considerations and thermal solutions offered by ATP, so NVMe SSDs can beat the heat and thus deliver reliable sustained performance over extended periods of time.

ATP Electronics Launches NVMe PCIe Gen4 DRAM-less SSDs With up to 18 Stage Adaptive Ace Thermal Throttling

2025-09-16 - Product Introduction ATP Electronics, a global leader in specialized storage and memory solutions, is excited to announce a new series of NVMe PCIe Generation 4 compact solid state drives (SSDs) equipped with self-engineered technology that overcomes the limitations of thermal throttling, delivers up to 40% power savings, and protects data with powerful security features.

HM82130 17-V Input 3-A Step-Down Power Module with Integrated Inductor

12/10/2024 - Datasheet

降压电源模块,STEP-DOWN POWER MODULE,HM82130

SMART’s DuraFlash CS210 SATA 2.5” Solid State Drives are Designed for General-purpose Industrial Applications

2022-01-28 - New Product Introduction SMART’s DuraFlash CS210 SATA 2.5” solid state drives are designed to meet the demand for a cost-effective solution in general-purpose industrial applications.

Simulating SSDs Payload Diversity and Realistic Usage

2025-09-12 - Technical Discussion ATP Electronics is committed to making sure that the SSDs customers get do not only look good on paper or on specification sheets. ATP can perform extended testing under conditions that simulate real-world workloads and stresses to ensure that the SSDs perform reliably within or even beyond their projected lifespan under the harshest operating conditions.

News | NAND Flash Storage Solutions for the Data-Driven 5G Era | ATP

2020-10-29 - Industry News Fifth-generation cellular network connection, or simply 5G, is the latest cellular technology iteration. ATP Electronics is ready and capable of meeting the data influx with its “Industrial Only” NAND flash memory and storage solutions.

Electronic Mall

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Auth. Dist.

Integrated Circuits

Discrete Components

Connectors & Structural Components

Assembly UnitModules & Accessories

Power Supplies & Power Modules

Electronic Materials

Instrumentation & Test Kit

Electrical Tools & Materials

Mechatronics

Processing & Customization