Nidec Provides Combined Units to Enhance Functionality and Develop a New Market for Logistics Solutions

Enhancing Functionality and Developing a New Market for Logistics Solutions

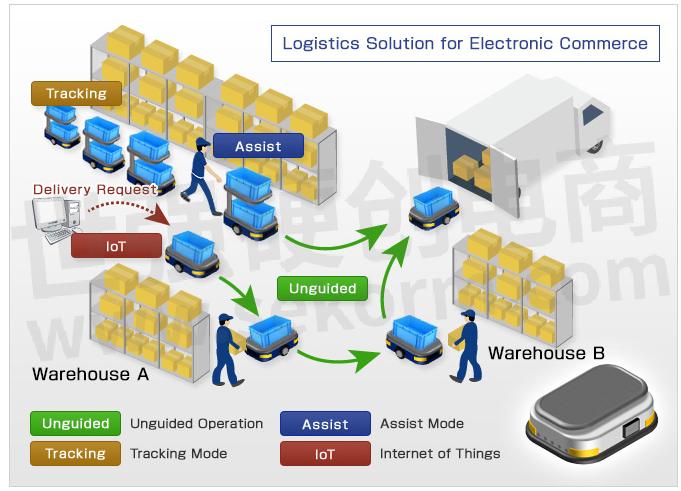

Although AGVs (Automatic Guided Vehicles) are currently mainly used in manufacturing-related applications, the market for AGVs specialized in logistics is expected to witness significant growth in the coming years. The trend of distribution centers—such as those of convenience stores and online shopping establishments—handling large varieties of different products in small quantities remains strong while labor costs are rising. At the same time, it is becoming increasingly difficult to staff warehouses. These factors combine to create an increase in demand for AGVs. AGVs used in distribution warehouses face different requirements than their manufacturing facility counterparts and need to be relatively small and silent as well as capable of unguided operation. As they are designed to substitute human labor, they carry loads of a few tens of kilograms as opposed to AGVs in the manufacturing industry expected to handle loads of several tons. Furthermore, they face higher constraints on acceptable noise levels due to their different operating environment. In addition, AGVs operating inside warehouses need to be flexible and capable of moving around freely, without relying on magnet tape attached to the floor, using laser radars and image recognition technology to detect and avoid obstacles.

We Also Offer Combined Units in Addition to Individual Components

The capabilities of the Nidec group allow us to supply not only individual components but also combined units, such as drive units, integrating brushless DC motors, high precision reduction gears, sensors, and other assets. Our brushless DC motors and high precision reduction gears, in particular, are the result of our leading-edge technology, and their high performance places us firmly ahead of the competition. Furthermore, we are also developing a new type of smart AGVs equipped with a number of advanced features such as the ability to track and follow other AGVs to move in convoys without physically being connected, an assist mode allowing the AGVs to work in tandem with humans, and the ability to predict and prevent breakdowns and suggest optimal operation settings by using IoT to collect and analyze position data, traveling data and vibration and noise pattern related data. Due to their low-noise properties, these new AGVs are also suited for operation in environments such as health facilities and museums as well, making the potential demand for them even higher.

Distribution Warehouses are Revolutionized as Smart AGVs Substitute Human Labor

- +1 Like

- Add to Favorites

Recommend

- What Batteries are Used for AGVs and AMRs?

- Nidec-Shimpo Newly Launches DC 24V Drive Modules with Two Allowable Load Capacities of 250kgf and 650kgf for AGVs and AMRs

- Robotics Specialist Innok Robotics Uses MTi-30 motion tracker from Xsens In its AGVs For Outdoor Space

- XSENS Motion Tracker Helps Innok Robotics Pioneers Sensor Fusion Agv Location In Complex Outdoor Terrains

- New VCSEL Module Technology: Increasing the Output of Spatial Recognition and Ranging Systems by 30% | ROHM

- ROHM’s New High Power 120W Laser Diode RLD90QZW8 for LiDAR: Increasing Measurement Range by Reducing Wavelength Temperature Dependence by 66%

- Melexis Sheds Light on Robotics and Mobility Technology at electronica 2024

- LEMON Photonics VCSEL Spot Laser Module Solution with Outstanding Performance

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.