Giving a Helping Hand to AC Servo Motors in Robots

Industrial automation is prevalent in various industries, factories, and our daily lives. For example, a robot that serves you in a restaurant, or trains you to play tennis. For these robots and automated machines to function, typically multiple motors need to be controlled in real-time. To achieve precise and synchronized motor control, the system master sends a message that passes through each node. The slave device reads the data and performs the actions requested. As the message passes from node to node, each node adds a delay. To eliminate this problem, Renesas offers MPUs like the RZ/T2M, RZ/N2L, or RZ/T2L, that incorporate high-speed, high-precision, real-time control with EtherCAT. This dramatically reduces delay times and incorporates industrial communication protocols including Ethernet/IP or Profinet RT/IRT on a single chip.

Renesas offers a comprehensive AC Servo Kit solution, using the RZ/T2L MPU, and features servo control with various communication protocols, as well as field sensors for data collection via remote IO to help speed up your motor control design.

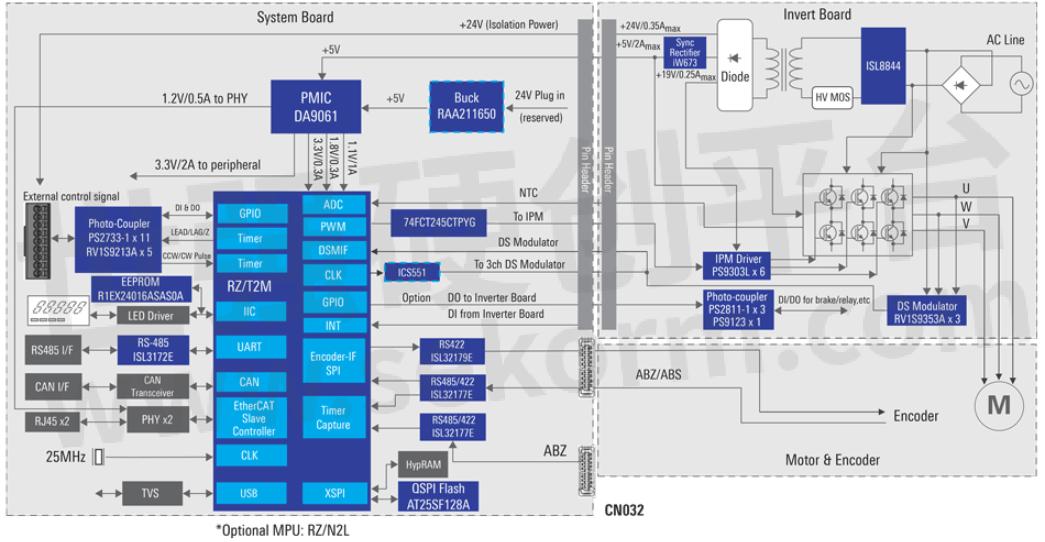

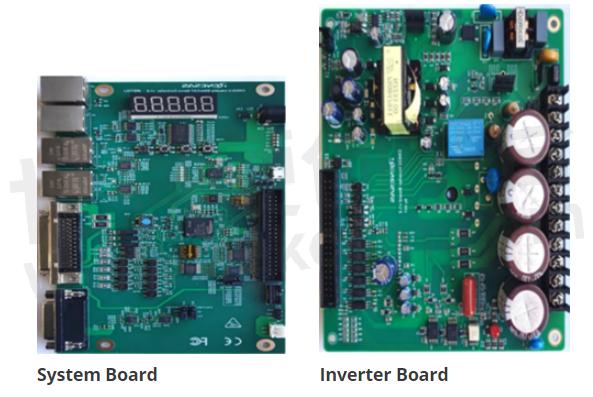

Figure 1. AC Servo Kit Solution

Renesas’ AC Servo Kit is an EtherCAT-compliant motor control solution that offers three key features for your evaluation.

· An EtherCAT software stack, that runs on the RZ/T2L MPU, and connects via TwinCAT®3.

· The motor board is connected via a high-speed RS-485 transceiver enabling a sub 1uS control loop time. The motor board features a Tamagawa encoder and a 200W servo motor and supports a sub 1uS current loop operation.

· Supports a partial CiA402 drive profile like profile position/cyclic synchronous position and velocity mode for motor control in EtherCAT communications.

Renesas evaluation kit includes all design documentation such as schematics, layout, source code, etc.

The AC Servo Kit's outstanding performance uses 11 high-performance Renesas devices. The core is a high-performance dual-core MPU RZ/T2L. The on-chip Cortex®-R52 800MHz processor easily handles industrial ethernet communications and motor control. The hardware encoder engine supports popular encoder protocols, like EnDat 2.2 (ENDAT), A-format (AFMT), ENDAT, BiSS-C, etc.

On the power side, the DA9061 high drive output PMIC simplifies the system power tree. Its 6A, 5ch output can power the main system and other peripherals. The RAA211450 synchronous buck regulator operates up to 42.5V input and is well suited to handle 24V servo system power rails.

Besides the MPU and power, the AC servo kit also incorporates versatile photocouplers, such as the PS2761B-1, PS2561D-1, PS8101, and RV1S9061A, for isolated communication or motor drive. The RV1S9353A, an optically isolated Delta–Sigma modulator, includes a 13.8-bit ENOB A/D converter, converts an analog voltage input into a 10MHz one-bit data stream, and quickly forwards current data for analysis.

The ISL32177E/ISL32179E RS-485 transceivers perform a key data transfer role with 20Mbps and ±16.5kV ESD protection.

The AT25SF128, a 128Mbit xSPI serial Flash memory with dual I/O, safely stores firmware and parameters. Finally, hardware and software open source is available to all customers.

- +1 Like

- Add to Favorites

Recommend

- Renesas’ New RZ/T2L Industrial MPU Enables Fast and Accurate Real-Time Control with EtherCAT Communication

- Renesas launches the RZ/T2M microprocessor that meet the needs of High-Performance and Multi-Functional Servo Motor

- Renesas DSP Solution on Renesas Lab on the Cloud, Input Analog Signals Directly From A Signal Generator To The Rx231 Microcontroller Evaluation Board

- Renesas‘ Semiconductor Manufacturing Factory (Naka Factory) Fire: Production Capacity Has Recovered to 88%

- Renesas Announces 10 New Winning Combinations Integrating Celeno and Renesas Products

- Renesas & Altran to Deploy First Social Distancing Wristwatch Using Ultra-Wideband Chipset with Low Rate Pulse

- Renesas and FAW Establish Joint Laboratory to Accelerate Development of Next-Generation Smart Vehicles

- Renesas Semiconductor Manufacturing Factory (Naka Factory)‘ Production Level Has Returned to 100%

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.