Evolution of Performance and Package from Beginning to Present of protection ICs

This post would like to talk about how the performance and the package of protection ICs have changed.

1. Comparison and transition of performance

The most important performance of protection ICs is an accuracy of the detection voltage. In particular, the accuracy of the overcharge detection voltage significantly affects the safety and performance of Li-ion batteries.

Considering the safety of the battery, it is desirable to set the overcharge detection voltage as low as possible. On the other hand, in order to increase the capacity of batteries, it is desirable to set the charge voltage as high as possible. However, if the charge voltage becomes higher than the overcharge detection voltage, the function of overcharge protection will be activated every time the battery is charged, and it will not be possible to charge 100% of battery capacity. Therefore, it is necessary to manage each setting of the charge voltage and the overcharge detection voltage with high accuracy so that these are not set in reverse.

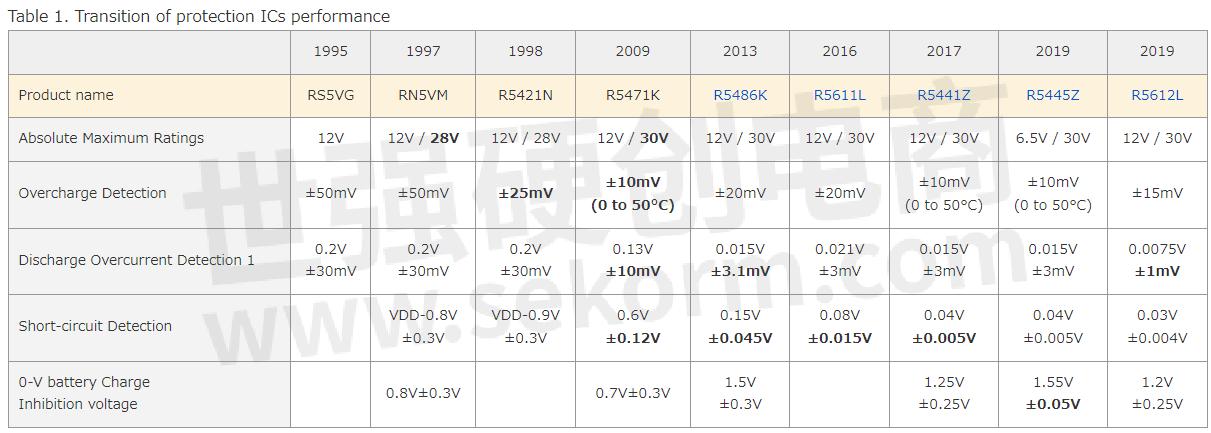

The accuracy of the overcharge detection voltage of the RS5VG, first protection IC, had ±50mV. The accuracy of a general voltage detector, as voltage detection ICs at that time, was ±2.5%. If a protection circuit was designed with this voltage detector, the accuracy of the overcharge voltage became ±106.25mV when the overcharge detection voltage was 4.25 V. The accuracy of the overcharge detection voltage of RS5VG was achieved more than twice as high as that of a general voltage detector at that time.

The accuracy of overcharge detection voltage has improved since that. In 1998, the R5421N achieved ±25mV, and in 2009, the R5471K achieved ±10mV under the temperature range of 0 to 50°C. It goes without saying that the evolution of technology in terms of both circuits and manufacturing processes had greatly contributed to the realization of ±10mV.

There is another important detection accuracy. It is overcurrent detection accuracy. In particular, the accuracy of discharge overcurrent detection has been emphasized.

The discharge overcurrent detection voltage of the RS5VG,first protection IC, was 0.2V±30mV. Because the discharge overcurrent function performs using an FET’s on-resistance and the FET is connected in series with the output line of the battery pack, the on-resistance of the FET directly affects the impedance of the battery pack. From the viewpoint of battery pack, it is desirable that the impedance become as lower as possible to flow a large current, therefore, the on-resistance of the FET has continued to decrease. Accordingly, the required value of the discharge overcurrent detection voltage of protection ICs also has decreased.

In 2009, the discharge overcurrent detection voltage of the R5471K achieved 0.13V with the accuracy of ±10mV. As explained in the previous column, with the adoption of overcurrent detection method using an external resistance instead of using on-resistance of FET, the overcurrent detection voltage dropped to 0.015V in 2013 at once by using a low external resistor. Accordingly, the accuracy improved to ±3.1mV. In 2019, the discharge overcurrent detection voltage and accuracy of the R5612L achieved 0.0075V±1mV.

As the discharge overcurrent has become lower and more accurate, the voltage and accuracy of short-circuit detection has also improved, as shown in Table 1.

In addition, the accuracy of the 0-V battery charge inhibition voltage also has improved. In 1997, the RS5VM had 0.8V±0.3V, and in 2019, the R5445Z achieved higher accuracy to 1.55V±0.05V. Some customers demand to use batteries until its voltage become a nearly limit voltage that can be safely used even the batteries are deeply discharged, therefore, they require high accuracy of the 0-V charge prohibition voltage.

Voltage tolerance, which is described as ”Absolute maximum ratings” in the Table 1, is an important performance other than the accuracy. Regarding absolute maximum ratings, the RS5VG, our first protection IC, had 12V for all pins of this protection IC. From the RN5VM in 1997, by setting the voltage tolerance separately for pins connected with the battery voltage and pins connected with outside of battery pack such as battery chargers or system load, it achieved high voltage tolerant as an entire protection circuit including protection ICs, even if all pins of protection ICs did not consist of high voltage tolerant elements. With this technology, the RN5VM was released as a high voltage tolerant protection IC without affecting its chip size significantly. In the RN5VM, absolute maximum ratings of pins connected with the battery voltage were 12V and that of pins connected with outside of battery pack, such as, battery chargers were 28V. After that, in 2009, the higher one became 30V, which continues to this day.

As described above, the performance of protection ICs has developed mainly on the accuracy of the overcharge detection voltage and the discharge overcurrent detection voltage, but the requirement for accuracy may continue.

2. Comparison and transition of package

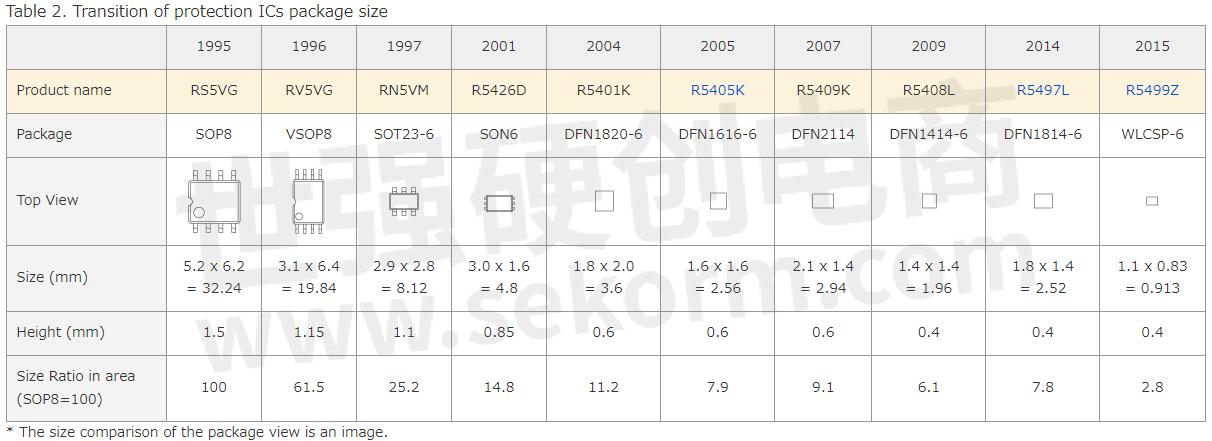

Li-ion batteries began to be used in portable video cameras in 1992, and they have grown significantly due to widespread use in mobile phones. Mobile phones have developed along with miniaturization, thinning, and weight reduction, battery packs have been also required to be smaller and thinner accordingly, and it has been also required to be smaller and thinner for protection ICs severely.

The package of the RS5VG, our first protection IC, was SOP8. The size of the package was 5.2 x 6.2 mm, which is unthinkable at present. Although, one year later, in 1996, it was packaged in VSOP8 and achieved a size reduction of nearly 40% compared to SOP8, unfortunately, evaluation by the market was not satisfactory. It didn't have significant impact on our customers.

One year later, in 1997, the RN5VM was packaged in SOT23-6 and achieved smaller size to less than 50% of the RV5VG, and 1/4 of the RS5VG. In addition, because this SOT23-6 package was used for common device such as transistors and was possible to keep cost down, it had a significant impact on the market in terms of both size and cost.

In 2004, the R5401K is packaged in the first leadless package, DFN1820-6. After that, miniaturization of the leadless package has been progressed. In 2015, the R5499Z adopted chip size package, WLCSP6, for the first time, and now the share of WLCSP in the market has increased.

The transition of protection ICs package size is shown in Table2.

In the 20 years from 1995 to 2015, the size of the package has been reduced to 2.8% in area, and the height of the package has also been reduced from 1.5 mm to 0.4 mm. Regarding the height, there are plans to make it further thinner in the future.

In recent years, Li-ion batteries have become widely used in small devices such as wearables and hearables equipment, and miniaturization and thinning are essential requirements in the market.

3. Conclusion

Basically, there are three parameters for managing battery safety: battery voltage, charge/discharge current, and battery temperature, therefore, I thought that the potential of function and performance for protection ICs was not so great when our first protection IC was developed, however, even now, more than 25 years after the emergence of protection ICs, new requirements from customers continue. Accordingly, we are making daily efforts to develop technology further and continue to develop evolved products.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.