Power Supply Stations Based on WIMA PowerBlocks Able to Withstand the Highest Current Pulses for Periods of Seconds

High current sources required as test devices or for transformation in metallurgy can now be designed by using WIMA PowerBlocks taking advantage of characteristics that have not been available before. The low internal resistance of double-layer capacitors which are offered by WIMA in cascaded construction makes them ideally suited to withstand the highest current pulses for periods of seconds.

Picture 1 presents a construction for discharge as of 230 V at 3000 A for 1.5 sec4 modules of 100 F/56 V each are vertically positioned and connected in parallel in the bottom area of the cabinet and thus represent 25 F altogether. The internal resistance of this array is lower than 33 mC This construction is provided with a copper terminal cross-section of 150 mm2. A commercially available charger with current limitations is used by the customer for charging. The module housings themselves are grounded.

Picture1: Current source with 25 F and 230V nominal voltage

For service purposes, during cabinet erection, the equipment is additionally fitted with an internal discharge device consisting of a power FET switch activating a discharge current of approx. 10 A when the non-release voltage is switched off at the switch in the door. Thus the discharge constant is about 8 minutes. Proper charging condition is signalized by a voltage display.

IF requested by the customer the modules can be supplied with active or with passive balancing. Moreover, a diagnostic signal for overvoltage or excess temperature can be provided.

Schematic design of a current source with a capacitance of 137 F and 600 V nominal voltage

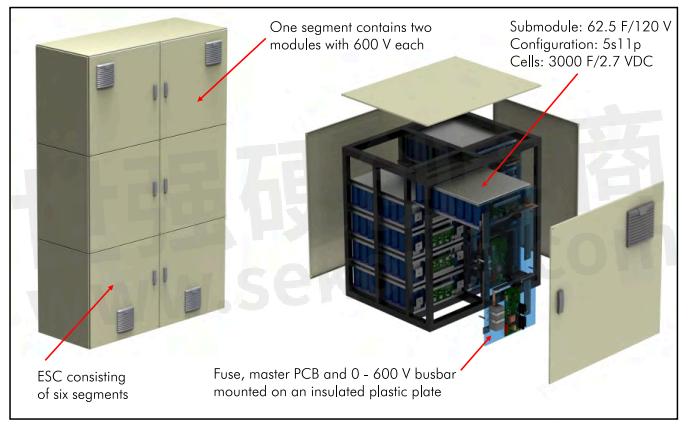

Picture 2 shows an energy storage with5 pcs.62.5 F / 120 V modules being connected in series to one rack of 600 V and 11 racks being connected in parallel to reach high capacitances. This construction serves to supply a power of 600 kW within 20 sec. During construction of the energy storage special emphasis was placed on:

●Maintenance friendliness (quick and easy replacement of individual modules within minutes only)

●Safety features (current/insulation monitoring,implementation of fuses,etc.)

●Monitoring of the individual string and cells(temperature, voltage)

●Compact design.

Picture2: Current source with 137 F and 600V nominal voltage

- +1 Like

- Add to Favorites

Recommend

- 6 Main Fields of Application for WIMA PowerBlock Module

- Start of Diesel Engine or A Micro-turbine Based on WIMA Powerblocks

- WIMA PowerBlocks Energy Storage Solutions with Long Lifetime >90,000 Hours

- Is a Custom Power Module Better than a General Power Module?

- SA356 High Power Transmission Module—A 48K Sampling Audio Transmission Module Featuring 3KM Transmission Distance and Low Latency

- Is a Custom Power Module Better than a Regular Power Module

- DC-DC Power Modules: Micro Power, Infinite Possibilities

- Neoway Cat.1 bis Modules Have No.1 Market Share in India Power IoT

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.