Some Question of Transient Voltage Suppressor

Q: What is TVS?

TVS (Transient Voltage Suppressor) is a pressure-limiting overvoltage protector, which presses high voltage to a safe range to protect the circuit behind, with faster reaction time than other protective elements, which makes TVS available to protect rapid destructive transient voltage lighting, switching, ESD, etc.

Q: What is TVS applicable to?

TVS is widely used in the overvoltage protection of sensitive electronic parts, including computers, communications, industrial products, consumer electronics, and automotive markets.

Q: What is the difference between glass passivation and O pickling processes for TVS?

1. Both the glass passivation process and the pickling OJ process are used to protect the TVS PN junction surface from oxidation and corrosion.

2. TVS are usually made of silicon material, because the silicon material has many advantages, such as a lower measured current and a high voltage resistance. They can modulate the voltage threshold by varying the doping concentration of the material.

3. Glass passivation is a process of forming a layer of glass film on the surface of silicon, the purpose is to isolate the oxygen on the silicon surface and the air outside world, preventing oxidation and corrosion. The pickling OJ process is used to remove pollutants and an oxide layer on the surface of silicon, complete the crystal fixation process, coating the surface with a layer of white glue. (commonly known as white glue)

4. Glass passivation is formed by glass powder sintering, and the temperature is above 800 degrees Celsius; it has high-temperature resistance, stable performance, and a complex process. For the chip slice is not too friendly, and control is not easy to crack or hidden crack problems, potential failure risk.

5. Acid washing OJ process has high adhesive characteristics, which is easy to form bubbles and be affected by the environment. For the normal use of consumer products, the probability of failure can be accepted by users.

Why Should SiPos Material Be Added To PN Or Scribing?

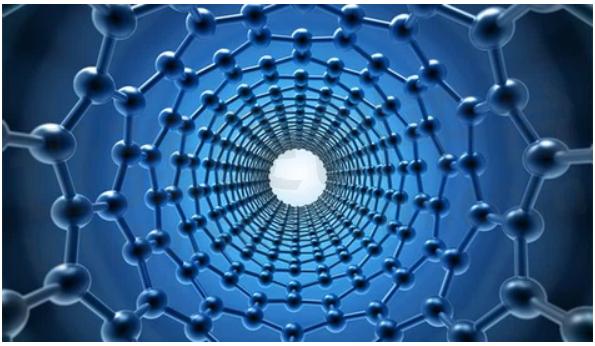

SiPos is a material used in the preparation of TVS transient suppression diodes, which is short for Silicon Passivated and is usually formed on SiO2 (silicon dioxide) films.

Q: What is the purpose of the inclusion of SiPos material?

1. Protect the structure of the diode: SiPos material can be covered on the surface of the diode, forming a protective layer to prevent oxygen and other harmful substances from entering the inside of the diode, reducing the external corrosion and pollution of the diode.

2. Improve electrical performance: SiPos material can improve the electrical performance of the diode, such as reducing the reverse leakage current and increasing the threshold voltage.

3. Enhance voltage resistance: SiPos material can enhance the voltage resistance of the diode and improve its ability to inhibit overvoltage.

- +1 Like

- Add to Favorites

Recommend

This document is provided by Sekorm Platform for VIP exclusive service. The copyright is owned by Sekorm. Without authorization, any medias, websites or individual are not allowed to reprint. When authorizing the reprint, the link of www.sekorm.com must be indicated.